The Sanford One-ton Motor Truck.

Page 8

Page 9

If you've noticed an error in this article please click here to report it so we can fix it.

First Details of an American-built Machine Now on the English Market.

Following closely upon our description. of the Pierce-Arrow truck, published in the issue of TEE COMMERCIAL Moron dated the 11th of last month, we are in a position to place before our readers particulars and illustrations of a smaller American-built industrial machine. This is the " Model K ". Sanftrad truck, which is being introduced into this country by the Universal Agency Co., 14a, Newcastle Street, Farringdon Street, EX. It has been sent over from America by the Sanford Truck Co., Syracuse, New York, who are manufacturing the machine in considerable numbers. A representative of this journal recently inspected the first truck to reach this country during its stay at the London bodybuilders, and found several commendable constructional features embodied in the model which at once showed that the machine is substantially built to withstand real hard work.

Two models are being turned out at the Syracuse factory ; they have a one-ton and V,--ton load capacity, respectively. It is the smaller model with which we are at present concerned, as being the only one which is marketed in this country for the time. being. At the outset, we must say that, although the truck is stated by the makers to be a one-tonner; the substantial nature of its build, in order to withstand the arduous work imposed upon the chassis by the average indifferent American roads, renders the model quite capable of handling loads in this country reasonably in excess of the catalogued one-ton.

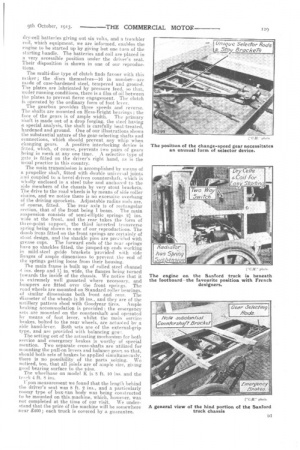

As one of our illustrations shows, the chassis is of the over-type construction, the engine being mounted underneath the footboaads. This feattsee allows for ample body space for a relatively short wheelbase, which latter point enables the machine to be handled very readily in traffic.. The engine is composed of four vertical cylinders, which are cast in pairs, the bore being 4 ins, and the length of stroke 41 ins. The engine, clutch and gearbox, as a selfcontained unit, are mounted on the three-point suspension principle, the housing for the gearbox and

clutch being directly bolted to the engine crank chamber. The unit is supported at its front end. with two lugs bolted to a transverse cross member of the frame, of rolled steel " I" section, the third point of suspension being effected behind the gearbox by means of a lug bolted to a transverse tube of ample diameter. The engine-control finger levers are mounted over the steering wheel ; regulation for both, spark and throttle is provided. The valves, which are interchangeable, are fitted with adjustable tappets, and the whole of the mechanism is enclosed in oil-tight doors, which are bolted flush with the cylinders.

We were particularly struck by the evidence of forethought. on the part of the designer to provide for easy access to the crankshaft bearings and reciprocating parts. This is accomplished by being able to completely remova one side of the crankcase, leaving the whole of the mechanism exposed. This plate is bolted to the near-side of the crank chamber. On the off-side there are two large sight doors fitted. The cooling

circulated by means of a centrifugal pump disposed on the near-side. Thc large cellular radiator is mounted on coil springs in order to damp out road shocks. The shaft which drives the pump also serves to actuate a Bosch high-tension magneto, a leather coupling disc being fitted where the two spindles join. Lubrication of the main bearings and big-ends is accomplished by a small rotary gear pump, which is driven off the end of the timing shaft. The. carburetter on the model which we saw w.a.s oil the Schebler make.

A special feature to be noted at this point is the compact and totally-enclosed governor mechanism which is fitted. This actuates the throttle and limits the speed of the machine to 16 miles an hour. The governor -can be operated independently of the carburetter, and it can be set to actuate the throttle at a predetermined speed, which setting can be sealed, so that it cannot be interfered with by the driver.

As showing the trend of American practice, means are provided for easy starting by the fitting of four re Ii.' dry-cell batteries giving out six volts, and a trembler coil, which equipment., we are informed, enables the engine to be started up by giving but one turn of the starting handle. The batteries and coil are placed in a very accessible position under the driver's seat. Their disposition is shown in one of our reproductions.

The multi-disc type of clutch finds favour with this maker; the discs themselves-16 in number—are made of case-hardened steel, tempered and ground. The plates are lubricated by pressure feed, so that, nudes running conditions, there is a film of oil between the plates to prevent fierce engagement. The clutch is operated by the ordinary form of foot lever. The gearbox provides three speeds and reverse. The shafts are mounted on Hess-Bright bearings ; the face of the gears is of ample width. The primary shaft is made Out of a drop forging, the steel having a special analysis, the shaft is carefully heat-treated, hardened and ground. One of our illustrations shows the substantial nature of the gear-selecting shafts and connections, which should prevent any whip when changing gears. A positive interlocking device is fitted, which, of course, prevents two pairs of gears 'being in mesh at any one time. A selective type of gate is fitted on the driver's right hand, as is the usual practice in this country.

The main transmission is accomplished by means of a propeller shaft, fitted with double universal joints and coupled to a beveldrive.n countershaft, which. is Wholly enclosed in a steel tube and anchored to the side members of the chassis by very stout brackets. The drive to the road wheels is by means of side roller chains, and we notice there is no excessive overhang of the driving sprockets. Adjustable radius rods are,

of course. fitted. The rear axle is of rectangular section, that of the front being I beam. The main suspension consists of semi-elliptic springs 214ins.

wide at the front, and the rear takes the form of tie ee-point support, the third inverted trensverse spring being shown in one of our reproductions. The dumb irons fitted on the front springs are certainly of stout design, and the shackle pins are pec,:sided with grease cups. The forward ends of the rear springs have no shackles fitted, the jumped-up ends working in mild-steel guide brackets provided with side naives of ample dimensions to prevent the end of the springs getting loose from their housing.

The main frame is built up of rolled steel channel 4 ins, deep and 1:; in. wide, the flanges being turned

towards the inside of the chassis. We notice that it is extremely well gusseted where necessary, and bumpers are fitted over the front springs. The road wheels are mounted on Standard roller bearings, or similar dimensions both front and rear. The diameter of the wheels is 36 ins., and they are of the urtillery pattern shod with Goodyear tires. Ample braking accommodation is provided the emergency sets are mounted on the countershaft and operated

by means of foot lever, whilst the main service brakes, bolted to the rear wheels, are aetuF>ted by a side hand-lever. Both sets are of the external-grip type, and are provided with balancinggety7.

The setting out of the actuating mechauism for both service and emergency brakes is worthy of special mention. Two separate cross-shafts are utilized for mounting the pulleon levers and balance gear; so that, should both sets of brakes be applied simultaneously,

there is no possibility of the parts seizing.Wc noticed, too, that all joirifs are of ample size, giving good bearing surface to the pins.

The wheelbase on model K is 8 ft. 10 ins, and the ti.:Ir!k 4 it. S Vpon measurement we found that the length behind the driver's seat was 8 ft. 2 ins., and a particularly

roomy type of box-van body was being cosistructed to be mounted on thisenachine, which, however, was not completed at the time of our visit. We understand that the price Of the machine will be somewhere near £400; each truck is covered by a guarantee.