Novel engine position o n n ew Bristol chassis

Page 56

Page 57

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

By A. J . P. Wilding

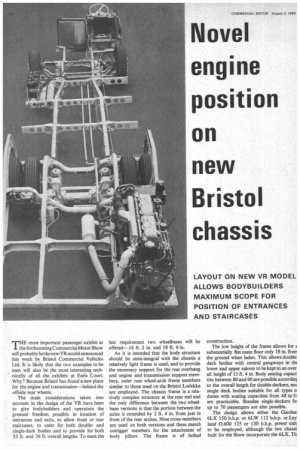

AMIMechE, MIRTE THE most important passenger exhibit at the forthcoming Commercial Motor Show will probably be the new VR model announced this week by Bristol Commercial Vehicles Ltd. It is likely that the two examples to be seen will also be the most interesting technically of all the exhibits at Earls Court. Why? Because Bristol has found a new place for the engine and transmission—behind the offside rear wheels.

The main considerations taken into account in the design of the VR have been to give bodybuilders and operators the greatest freedom possible in location of entrances and exits, to allow front or rear staircases, to cater for both doubleand single-deck bodies and to provide for both 33 ft. and 36 ft. overall lengths. To meet the last requirement two wheelbases will be offered-16 ft. 2 in. and 18 ft. 6 in.

As it is intended that the body structure should be semi-integral with the chassis a relatively light frame is used, and to provide the necessary support for the rear overhang and engine and transmission support members, outer rear wheel-arch frame members similar to those used on the Bristol Lodekka are employed. The chassis frame is a relatively complex structure at the rear end and the only difference between the two wheelbase versions is that the portion between the axles is extended by 2 ft. 4 in. from just in front of the rear arches. Nine cross-members are used on both versions and these match outrigger members for the attachment of body pillars. The frame is of bolted construction.

The low height of the frame allows for g substantially flat main floor only 18 in. frorr the ground when laden. This allows double• deck bodies with central gangways in di( lower and upper saloon to be kept to an over all height of 13 ft. 4 in. Body seating capaci. ties between 80 and 90 are possible aecordit.q to the overall length for double-deckers, an single deck bodies suitable for all • types o duties with seating capacities from 48 to are practicable. Standee single-deckers fa up to 70 passengers are also possible.

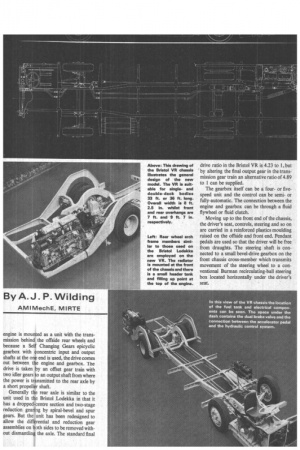

The design allows either the Gardne: 6LX 150 rb.h.p. or 6LW 112 b.h.p. or Ley land 0.600 125 or 130 b.h.p. power unit to be employed, although the two chassi built for the Show incorporate the 6LX. Th engine is mounted as a unit with the transmission behind the offside rear wheels and because a Self Changing Gears epicyclic gearbox with concentric input and output shafts at the one end is used, the drive comes out between the engine and gearbox. The drive is taken by an offset gear train with two idler gears to an output shaft from where the power is transmitted to the rear axle by a short propeller shaft.

Generally the rear axle is similar to the unit used in the Bristol Lodekka in that it has a dropped-centre section and two-stage reduction gearing by spiral-bevel and spur gears. But the unit has been redesigned to allow the differential and reduction gear assemblies on both sides to be removed without dismantling the axle. The standard final drive ratio in the Bristol VR is 4.23 to 1, but by altering the final output gear in the transmission gear train an alternative ratio of 4.89 to 1 can be supplied.

The gearbox itself can be a fouror fivespeed unit and the control can be semior fully-automatic. The connection between the engine and gearbox can be through a fluid flywheel or fluid clutch.

Moving up to the front end of the chassis, the driver's seat, controls, steering and so on are carried in a reinforced plastics moulding raised on the offside and front end. Pendant pedals are used so that the driver will be free from draughts. The steering shaft is connected to a small bevel-drive gearbox on the front chassis cross-member which transmits movement of the steering wheel to a conventional Burman recirculating-ball steering box located horizontally under the driver's seat. An advantage of this design, apart from the freedom given to the chassis designer, is that the length of the drag link is reduced without the need for a relay lever. Powersteering is not included in the standard specification, but this can be incorporated without difficulty.

Braking is by a split-circuit air-pressure system, the feed to the front and rear axles being independent. There are three air reservoirs, one for each of the brake circuits and one for auxiliaries such as the gearbox and any door-opening equipment that may be fitted in the body. A twin-cylinder compressor is mounted on the engine and this is driven in the case of the Gardner 6LX by a Ferodo Poly-V belt. Girling brake units are employed, the brake drums being 15.5 in. all round and the shoes 6 in. wide at the front and 8 in. at the rear. Total frictional area is 848 sq. in.

Standard suspension is by semi-elliptic springs, 3.5 in. wide all round and 50 in. long at the front and 57 in. at the rear. It is likely that alternative suspension systems, such as air, will be offered at a later date.

The engine-cooling system includes a cross-flow radiator located at the extreme front end of the chassis and the diameter of the pipes to the engine is 1.25 in. Following Bristol practice on other models a fan is not fitted as standard, it having been found that ram effect is sufficient. In circumstances where it could be desirable, a thermostatically controlled electric-motor-driven fan could be fitted.

A rectangular fuel tank with a capacity of 36 gal. is mounted on the offside of the vehicle forward of the front axle, and according to the body fitted, the tyres can be 9.00 or 10.00-20, 12, 14 or 16-ply. The electrical system includes an alternator and the starter is mounted on the gearbox; it is on the offside of the engine, as is the alternator. It is intended that the batteries are positioned in the body above the nearside front wheel arch where they can be under a longitudinal seat. Lead acid batteries with a capacity of 140 ah. are standard, but alkaline batteries can be supplied.

One of the most important points that has been taken into account in designing the VR is maintenance. Here, purchasers get the advantages of dealing with a company which has had close links with an operating organization. Most work can be done from outside the vehicle without using a pit. All engine auxiliaries are accessible through an inspection panel at the rear of the body on the offside and the engine and transmission can be removed as a unit from the rear.

Similar access panels at the front offside corner will facilitate maintenance of electrical components and fuses (on the side) and the hydraulic accelerator control and dual brake valve, both of which are in a space above the pedal mountings.

Taken altogether the Bristol VR chassis appears a very good design with considerable attention paid to detail and service

ability. There are many praiseworthy features and about the only thing that looked out of place was an old-fashioned handbrake lever which lies horizontally on the right of the driver's seat. This point could be revised, as I understand that spring brakes are being considered to fulfil the parking requirements, and if these become legal a small hand lever could replace the present unit.

As with other rear-engined p.s.v., recent changes in the Construction and Use Regulations have made the design used by Bristol possible. This is particularly true of the increased axle load permitted-10 tons as against 9 tons. And with a rear overhang of 9 ft. 7 in. the VR is just within the latest 60 per cent of wheelbase limit in the case of the 16 ft. 2 in. model. This dimension and the front overhang of 7 ft. are the same on the 16 ft. 2 in. and 18 ft. 6 in. chassis.

At first sight many people will think that there must be some problem of weight distribution on a chassis which has an engine and gearbox weighing in all about 1.25 tons mounted at the rear corner. But it has been calculated that with a laden double-decker the weight difference between the offside and nearside wheels is only 7 cwt. and that this will mean that the body floor is horizontal whenever the vehicle is travelling on a normal cambered road.

No weight figures are yet available for the Bristol VR when laden, but for the bare chassis the front axle carries 1 ton 6 cwt. and the loading at the rear is 4 tons.