A Heating Unit with No Moving Parts

Page 35

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

An Automatically Controlled Self-contained Vehicle-heating Device that Gives 20,000 B.Th.t.l.s for Every 1.23 Pints of Fuel Consumed

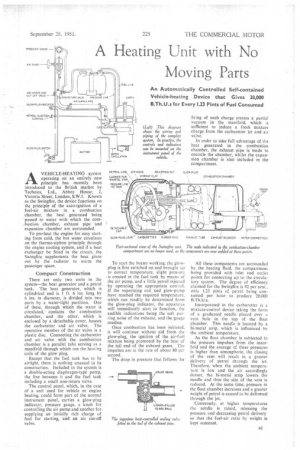

AVEHICLE-HEATING system operating on an entirely new principle has recently been introduced to the British market by Technics, Ltd., Abbey House. 2, Victoria Street, London, S.W.1. Known as the Swingfire, the device functions on the principle of the auto-ignition of a fuel-air mixture in a combustion chamber, the heat generated being passed to water with which the com-bustion chamber, exhaust pipe and expansion chamber are surrounded.

To pre-heat the engine for easy starting from cold, the hot water circulates on the then-no-siphon principle through the engine cooling system, and if a heat exchanger be fitted in the circuit, the Swingfire supplements the heat given out by the radiator to warm the passenger space.

Compact Construction

There are only two units in the system—the heat generator and a petrol tank. The beat generator, which is cylindrical and is 1 ft. 6 ins, long by 6 ins, in diameter, is divided into two parts by a water-tight partition. One of these, through which the water is circulated, contains the combustion chamber, and the other, which is enclosed by a detachable cover, houses the carburetter and air valve. The operative member of the air valve is a plastic disc. Connecting the carburetter and air valve with the combustion chamber is a parallel tube serving as a manifold through which run the healing coils of the glow plug.

Except that the fuel lank has to be airtight, there is nothing unusual in its construction. Included in the system is a double-acting diaphragm-type pump, the line between it and the fuel tank including a small non-return valve.

The control panel, which, in the case of a unit used for vehicle or engine heating, could form part of the normal instrument panel, carries a glow-plug indicator, pressure gauge, a knob for controlling the air pump and another for supplying an initially rich charge of fuel for starting, and an air cut-off valve. To start the heater working. the glowplug is first switched on and brought up to correct temperature, slight pres,ure • is created in the fuel tank by means of the air pump, and a little petrol injected by operating the appropriate control. If the vaporizing coil and glow-pump have reached the required temperature, which can readily be determined from the glow-plug indicator, the apparatus will immediately startto function, the audible indications being the soft purring noise of the exhaust, and the gauge reading.

Once combustion has been initiated, it will continue without aid from the glow-plug, the ignition of the air-fuel mixture being promoted by the heat of the tail end of the exhaust gases. The .impulses are at the rate of about 80 per second.

The drop in pressure that follows the tiring of each charge creates a partial vacuum in the manifold, which is sufficient to induce a fresh mixture charge from the carburetter jet and air valve.

In order to take full advantage of the heat generated in the combustion chamber, the exhaust pipe is made to encircle the chamber, whilst the expansion chamber is also included in the compartment.

All these components are surrounded by the heating fluid, the compartment being provided with inlet and outlet points for connecting up to the circulatory system. The degree of efficiency claimed for the Swingflre is 92 per cent., only 1.23 pints of petrol being consumed per hour to produce 20,000 11.Th.11,s.

Incorporated in the carburetter is a

mixture-control device taking the form of a graduated needle placed over a vent hole in the top of the float chamber. This needle is located by a hi-metal strip, which is influenced by the ambient temperature.

As the float chamber is subjected to the pressure impulses from the manifold and the average of these pressures is higher than atmospheric, the closing of the vent will result in a greater delivery of petrol through the jet. Therefore, when the ambient temperature is low and the air accordingly denser, the hi-metal strip lowers the needle and thus the size of the vent is reduced. At the same time, pressure in the float chamber increases and a greater weight of petrol is caused to be delivered through the jet.

Conversely, at higher temperatures the needle is raised, releasing the pressure and decreasing petrol delivery so that the fuel-air ratio by weight is kept constant. Another ingenious device is a springloaded valve arranged in the tail-pipe of the exhaust. Under normal conditions this valve is held off its seating by a liquid-filled glass ball anchored to the base against which the spring abuts, In the event of the exhaust gases exceeding a predetermined temperature, the liquid in the ball expands, the ball bursts, the spring snaps on to its seating, and the device immediately stops.

The beat-generating unit can be installed either vertically or horizontally, but the carburetter, which has a normal float chamber, must be arranged vertically. This presents no difficulty as it is mounted on a large-diameter spigot,

around which it can be moved and secured in any position desired. Cornplcte with tank, starter, fixing brackets etc., the heating unit weighs 26 lb. The weight of a standard Swing-fire tient exchanger, less fluid, is about 40 lb.

Such a device is particularly suitable for vehicle heating. but it has numerous applications where an independent source of heat may be required in circumstances where mains gas or electricity are not available.

When used for vehicle heating with heat exchangers in operation, the air supply to the exchangers can be taken either from inside or outside the vehicle. In the case of buses or coaches already equipped with a heating system in which engine heat is utilized, the installation of the Swingfire to supplement the engine heat presents no difficulties.

A normal location for the heating unit would be under the floor of the vehicle, connections being taken to one or more heat exchangers fixed under the seats.

"The Commercial Motor" understands that the Clayton Dewandre Co., Ltd., which is making heat exchangers to go with the Swingfire unit, is also installing the complete system in the passenger vehicle used by that company for experimental purposes.