The•Latest Practice in Garage Layout

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

I N 1949, London Transport evolved a garage layout that was to form a basis for future premises. It was realized that efficiency depended in a large measure on the grouping of as many as possible of the major facilities so as to reduce to a minimum the effort required on the part of individual operatives. In addition, the design included an entirely new type of pit for major dock work.

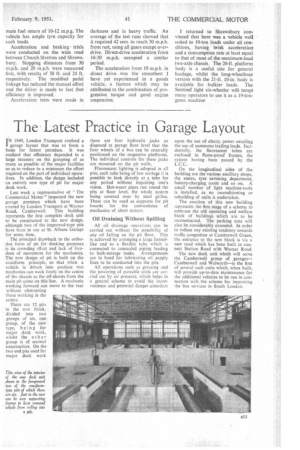

Last week a representative of "The Commercial Motor" inspected the new garage premises which have been erected by London Transport at Warner Road, Camberwell. This building represents the first complete dock unit to be constructed to the new design, although two of the improved-type pits have been in use at St. Albans Garage for some time.

The principal drawback to the orthodox form of pit for docking purposes is its crowding effect and lack of freedom of movement for the mechanics. The new design of pit is built on the cruciform principle, so that when a vehicle is driven into position two mechanics can work freely on the centre of the chassis as the off-shoots from the main pit come on this line. A mechanic working forward can move to the rear without obstructing those working in the centre.

There are 12 pits in the new block, divided into two groups of six, one group, of the new type, being for major dock work, whilst the other group is of normal construction. On the two end pits used for major dock work there are four hydraulic jacks so disposed at garage floor level that the four wheels of a bus can be centrally positioned. on the respective platforms. The individual controls for these jacks are mounted on the pit walls.

Fluorescent lighting is adopted in all pits; each tube being of low wattage it is possible to look directly at a tube for any period without impairing one's vision. Hot-water pipes run round the pits at floor level, the whole system being covered over by steel grilles. These can be used as supports for pit boards for the convenience of mechanics of short stature.

Oil Draining Without Spilling

All oil drainage operations can be carried out without the possibility of any oil falling on the pit floor. This is achieved by arranging a large tunnellike end to a flexible tube which is connected to concealed piping leading to bulk-storage tanks. Arrangements are in hand for lubricating oil supply lines to be conducted into the pits.

All operations such as greasing and the powering of portable tools are ear.ried out by air pressure, which helps in a general scheme to avoid the inconvenience and potential danger attendant upon the use of power entailing the use of numerous trailing leads. Incidentally, the fluorescent tubes are enclosed in flame-proof frames, the .system having been passed by the

On the longitudinal sides of the building are the various ancillary shops, the stores, tyre servicing department, battery-charging room and so on. A small number of light machine-tools is installed, as no reconditioning or rebuilding of units is undertaken.

The erection •of this new building represents the first stage of a scheme to embrace the old operating and welfare block of buildings which are to be reconstructed. The parking area will also be considerably extended. In order to reduce any existing tendency towards traffic congestion at Camberwell Green, the entrance to the new block is via a new road which has been built to connect Station Road with Warner Road.

The new dock unit which will serve the Camberwell group of garages— Camberwell. and Walworth—is the first of several such units which, when built, will provide up-to-date maintenance for the additional vehicles to be run in connection with the scheme for improving the bus services in South London.