Sentinel Light Six Scores on Trunk Haulage

Page 42

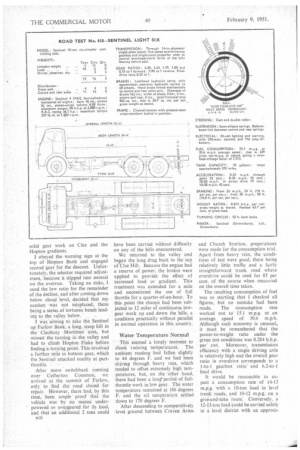

Page 43

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

says

L J. COTTON, M.I.R.T.E.

THE Sentinel light six-wheeler has a deceptive performance. From the cab, the engine has all the characteristics of a six

cylindered unit. Hills are climbed with ease and on level ground the overdrive gear can be employed to maintain a fast schedule with economy in fuel. My impression, early in the trials, was that the 10-ton load rating could be exceeded on normal trunk haulage without greatly affecting the performance, and the results of 100 miles' running proved this to be so.

The prototype embodied the chassis frame of the long-wheelbase four-wheeler, equipped with the units of the short-wheelbase model, and a trailing axle was added. The success of this arrangement prompted the maker to produce two similar models of 14-ft. Si-in. and 15-ft. 6i-in, wheelbase, powered by the standard horizontal fourcylindered 90 b.h.p. engine with the Ricardo Mark III combustion system

This power unit has already demonstrated its economy ,and, apart from a change in crankshaft material to a nitrided chromium RS molybdenum-steel die forging, and hardened gears driving the fuel pump, no other alteration has been made from the original design. Experience has shown that no greater wear occurs on the lower side of the cylinder bores, although the engine is horizbntally mounted. Further to prolong bore, life, the unit has Austenitic cast-iron liners, the inner surface of which is plated with a porous chromium deposit.

Transversely Mounted Pump

The fuel-injection pump is carried transversely at the front of the engine in an accessible position for maintenance, and is protected from dirt or water by a steel sheet which extends across the front of the unit. Injectors of pintle pattern are fitted, the spray angle being 12 degrees; heater plugs are provided for cold starting.

A new type of mounting, normally reserved for passenger vehicles. -is used for the power unit, which is accommodated amidships in the frame behind the cab. There are three Metalastik rubber-bonded pads at the front and two inclined pads of a similar type at the rear. The axis of suspension is on a line formed by the focal points of the front and rear mountings. In addition, there is a radial arm, attached to the frame through Metalastik units, to limit fore-andaft movement of the engine during accelerating or braking.. Buffer stops, acting against a cross-member, restrict angular movement during excessive torque reaction, such as engine oscillation, gear changing or stopping.

The engine is retained within the width of the frame, with the crankshaft offset from the centre line of the chassis. This makes the base or cylinder heads easily accessible from the sides of the vehicle. A skilled fitter and mate can strip the engine in position in two hours. It takes 7 rnins, to move the fuel pump and 45 mins. to take Off the complete tinung Cover to inspect rhe.chain arid gears.

The twin cylinder heads, with rocker gear and valve covers, can be rerrioved in 45 mins. and the four pistons and connecting rods withdrawn in 20 mins. If necessary, the complete engine, clutch and gearbox can be changed in approximately hours.

A single propeller shaft, with mechanically jointed couplings, transmits power to the central overhead-worm gear of the driving axle, which is a conventional fully floating unit with a sturdy forged case. The rear ends of the driving-axle springs are linked to the front of the trailingaxle springs by rocking beams. These are pivoted to proportion the load in the ratio of seven to five, the larger portion of the load being imposed on the driving axle.

The spring ratings are arranged for their respective loads and twin tyres are fitted to all four bogie wheels. The tyres of all wheels are of the same size and the brake components of the second and third axles are common, Girling units being fitted in all six drums.

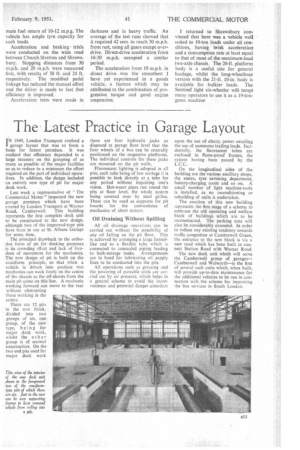

Lighter Pedal Effort A larger mastery cylinder, of 2-in. bore, is used in the Lockheed hydraulic brake servo system, in place of the unit formerly fitted, and the pedal linkage is changed to reduce the manual effort required for its operation. The hydraulic pump is driven from the gearbox output shaft and supplies fluid under pressure to an accumulator attached to a frame side member.

The vehicle supplied for test was the short-wheelbase version with a 20-ft. platform body. In registration condition, it weighed 5 tons 7 cwt., but with a full tank of fuel, accessories and tools, the unladen weight was 5 tons 11 cwt. Five 2-ton castings, secured against movement, were -then loaded and test equipment was attached to measure the performance.

As the chassis had not completed its running-in period, I planned the day's trial to add 80 miles before measuring acceleration or consump

tion rates. At first I rode as passenger from Shrewsbury to Ludlow. The works driver was new to this type of chassis, his particular liking being the larger six-cylindered trailer model. Nevertheless, he made perfect gear changes and full use of the gearbox overdrive.

The new engine suspension system makes a remarkable difference to the goods model, and apart from a slightly longer delay in gear changing, when compared with the 9.12litre engine, there was no indication in the cab that only a four-cylindered unit was installed. Second gear was engaged for a smooth start on level ground and the overdrive, which is as silent in use as direct drive, was brought into use at 25 m.p.h.

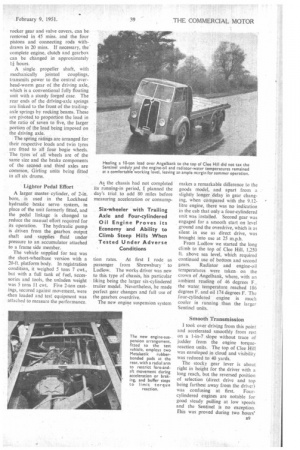

From Ludlow we started the long climb to the top of Clee Hill, 1;250 ft. above sea level, which required continued use of bottom and second gears. Radiator and engine-oil temperatures were taken. on the crown of Angelbank, where, with an ambient reading of 46 degrees F.. the water, temperature reached 186 degrees F. and oil 174 degrees F. The four-cylindered engine is much cooler in running than the larger Sentinel units.

Smooth Transmission took over driving from this point and accelerated smoothly from rest on a 1-in-7 slope without trace of judder from the engine torquereaction units. The top of Clee Hill was enveloped in cloud and visibility was reduced to 40 yards.

The stocky gear lever is about right in height for the driver with a long reach, but the reversed position of selection (direct drive and top being farthest away from the driver) was confusing at first. Fourcylindered engines are notable for good steady pulling at low speeds and the Sentinel is no exception. Ibis was proved during two hours' solid gear work on Clee and the Hopton gradients.

I obeyed the warning sign at the top of Hopton Bank and engaged second gear for the descent. Unfortunately, the selector required adjustment. because it slipped into neutral on the overrun. Taking no risks, 1 used the low ratio for the remainder of the decline, and after coming down below cloud level, decided that my caution was not misplaced, there being a series of tortuous bends lead ing to the valley below. , was aiming to take the Sentinel up Farlow Bank, a long, steep hill in the Cleobury Mortimer area, but missed the turning in the valley and had to climb Hopton Flake before finding a turning point. This involved a further mile in bottom gear, which the Sentinel attacked readily at partthrottle.

After more switchback running over Catherton Common, we arrived at the summit of Farlow, only to find the road closed for repair. However, there had, by this time, been ample: proof that the vehicle was by no means underpowered or overgeared for its load, and that an additional 2 tons could n10 have been carried without difficulty on any of the hills encountered.

We returned to the valley and began the long drag back to the top of Gee Hill. Because the engine had a reserve of power, the brakes were applied to provide the effect of increased load or gradient. This treatment was extended for a mile and necessitated the use of full throttle for a quarter-of-an-hour. To this .point the chassis had been subjected to 12 miles of continuous lowgear work up and down the hills, a condition practically without parallel in normal operation in this country.

Water Temperature Normal

This seemed a timely moment to check running temperatures. The ambient reading had fallen slightly to 44 degrees F. and we had been driving through heavy rain, which tended to offset extremely high temperatures, but, on the 'other hand, there had been a long period of fullthrottle work in low gear. The water temperature remained at 186 degrees F. and the oil temperature settled down to 170 degrees F.

After descending to comparatively level ground between Craven Arms and Church Stret ton, preparations were made for the consumption trial. Apart from heavy rain, the conditions of test were good. there being relatively little traffic and a fairly straightforward trunk road where overdrive could be used for 85 per cent. of the course when measured on the overall time taken.

The resulting consumption of fuel was so startling that I checked all figures, but no mistake had been made. The consumption rate worked out to 15.1 m.p.g. at an average speed of 30.6 m.p.h. Although such economy is unusual, it must be remembered that the power-to-weight ratio under the given test conditions was 0.284 b.h.p. per cwt. Moreover, transmission efficiency with a single driving axle is relatively high and the overall gear ratio in overdrive corresponds to a 1-to-1 gearbox ratio and 6.2-to-1 final drive.

It would be reasonable to expect a consumption rate of 14-15 m.p.g. with a 10-ton load in level trunk roads, and 10-12 mpg. on a give-and-take route. Conversely, a 12-13-ton load could be carried safely in a level district with an approxi

mate fuel return of 10-12 m.p.g. The vehicle has ample tyre capacity for such loads.

Acceleration and braking . trials were conducted on the wide road between Church Stretton and Shrewsbury. Stopping distances from 30 m.p.h. and 20 m.p.h. were measured first, with results of 58 ft. and 24 ft. respectively. The modified pedal linkage has reduced the manual effort and the driver is made to feel that efficiency is improved.

Acceleration tests were made in

darkness and in heavy traffic. An average of the test runs showed that it required 42 secs, to reach 30 m.p.h. from rest, using all gears except overdrive. Direct-drive acceleration from 10-30 m.p.h. occupied a similar period.

The acceleration from 10 m.p.h. in direct drive was the smoothest I have yet experienced in a goods vehicle, a feature which may be attributed to the combination of progressive torque and good engine suspension. I returned to Shrewsbury convinced that here was a vehicle well suited to 10-ton loads under all conditions, having brisk acceleration and a consumption rate at least equal to that of most of the maximum-load two-axle chassis. The 20-ft. platform body is a useful size for general haulage, whilst the long-wheelbase version with the 21-ft. 10-in, body is available for bulkier loads. The Sentinel light six-wheeler will tempt many operators to use it as a 19-tongross machine