BRAKE CONTROL BY THE ACCELERATOR.

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

A Novel System in which the Four-wheel Brakes are Operated Through the Medium of a Suction-controlled Servo Cylinder.

TEIF suotion-operated servo motor which employs the depression created in the inlet manifold of a petrol engine, when the throttle is closed, to augment the driver's efforts in applying the brakes, has become very popular on commercial vehicles during the past two years. This is particularly so on those chassis which are designed for high-speed passenger work.

Consequently it is very interesting to record the evolution of a new way of utiliziug this servo principle, which is the invention of a Swiss engineer.

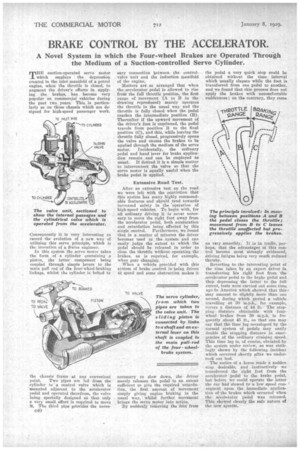

In this system the servo motor takes the form of a cylinder containing a piston, the latter • component being coupled through, simple levers to the main pull rod of the font-wheel-braking linkage, whilst. the cylinder is bolted to

the chassis frame at any convenient point. Two pipes are Jed from the cylinder to 'a control valve which is mounted adjacent to the accelerator pedal and operated therefrom, the valve being specially designed so that only a very small effort is required to move it. The third pipe provides the neces 040 sary connection between the controlvalve unit and the induction Manifold of the engine.

Natters are so arranged that when the accelerator pedal is allowed to rise from the full throttle position, the first range of movement (A to B in the drawing reproduced) merely operates the throttle in the usual way and the throttle is fully closed when the pedal reaches the intermediate position (B). Thereafter if the upward movement of the driver's foot is continued, the pedal travels from position B to the final position (C), and thie, while leaving the throttle fully closed, progressively opens the valve and causes the brakes to be applied through the medium of the servo motor. Incidentally, the ordinary pedal and hand lever for brake application remain and can be employed as usual. If desired it is a simple matter to interconnect the valve so that the servo motor is equally useful when the brake pedal is applied..

Extensive Road Test.

After an .extensive test on the road we were left with the conviction that this system has many highly commendable features and should tend towards increased safety in the 'operation of high-speed vehicles. To begin with, for all ordinary driving it is never necessary to move the right foot away from the accelerator pedal, both acceleration and retardation being effected by this single control. Furthermore, we found that in a matter of minutes the driver becomes need to the system and can easily judge the extent to which the pedal should be released in order to close the throttle without operating the brakes, as is required, for example, when gear changing.

When a vehicle provided with this system of brake control is.heing driven at speed and some obstruction makes it

necessary to slaw down, the driver merely releases the pedal to an extent sufficient to give the required -retarda-tion, the first amount of movement simply giving engine braking in the usual way, whilst further movement brings the servo .motor inte action. .

By suddenlyremoving the foot from

the pedal a very quick stop could be obtained without the time interval which usually elapses while the foot is transferred from one pedal to another, and we found that this process does not apply the brakes with uncomfortable suddenness ; on the contrary, they come on very smoothly. It is in traffic, perhaps, that the advantages of this con.trol become most strongly evidenced, driving fatigue being very much reduced thereby.

. Reverting to the interesting point of the time token by an expert driver in transferring his .right foot from the „ accelerator pedal to the brake pedal and then depressing the latter to the full extent, tests were carried out some time ago in America which showed that this May amount to slightly mere than One second, during which period a vehicle travelling at 30 M.p.h., for example, covers a distance of 44 ft. The stopping distance obtainable with fourwheel brakes from 3() m,p.h. is. frequently about 45 ft., so that one may say that the time lag occasigned by the normal system of pedals may easily double the stopping distance in emergenciet at the ordinary cruising speed. This time lag is, of Course, obviated-by the system under review, as was strikingly shown by the following incident which occurred shortly after we undertook our test.

The antics of a horse made a sudden stop desirable, and instinctively we transferred the right foot from the accelerator .Pedal to the brake pedal, but before we could operate the latter the car had 'slowed to a low speed consequent upon the immediate application of the brakes which occurred when the accelerator Pedal was released. This showed clearly the safe nature of the new system. A point that does not occur to anyone, until he has tried the system is the case with which it enables a -vehicle to be stopped and restarted up hill, because it is quite unnecessary to operate either the brake pedal or hand lever. In order to come to a standstill the driver simply releases the accelerator pedal, allowing the gradient and the servo motor to stop the car while he declutches and slips the gear lever into neutral. Thereafter, the idling engine maintains the braking and holds the vehicle so long as the accelerator pedal is not operated.

Here we thought an element of risk might arise if, so soon as the vehicle came to a stop, the engine were inadvertently allowed to stop also, but we forind that the valve would then hold the vacuum for some time, so that not until half a minute or so had elapsed did the brakes begin to slip. In this period of time the driver can, of course, apply the hand brake, chock the rear wheels, or restart the engine, without difficulty.

Restarting on a hill is very simple, because, after engaging first gear, the driver has only to depress the accelerator pedal while letting in the clutch; this simple process releases the brakes concurrently with the speeding up of the engine, and it is not necessary to make use of the hand brake.

We also tested the brakes with the vehicle running in neutral and the engine switched off so as to cut out the servo action, but found that adequate retardation could be obtained by using the brake pedal or the hand lever.

The sectioned drawings which we re produce make the principle of the device quite clear, and it will be seen that the valve itself consists of a hardened-steel rod, turned to two diameters, which slides in a hole bored in a bronze casting. It is controlled by light springs and by an L-shaped lever coupled to the accelerator pedal. When the Pedal is fully released the valve provides a connection between the servo cylinder and the inlet pipe, whilst -upon depressing the pedal this connee. tion is broken and an atmospheric connection established which balances the pressures on each side of the servomotor piston.

This interesting mechanism is being developed in England by Badertscher Va.cuumbrake, Ltd., North°lt Road, South Harrow, Middlesex, which concern is making the servo motor in sizes suitable for various weights of private car and commercial vehicle, The prices are moderate and fitting the device to an existing chassis is, we are told, a very simple matter, occupying not more than 45 hours. The system is :certainly one of considerable interest.