by Johnny Johnson

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

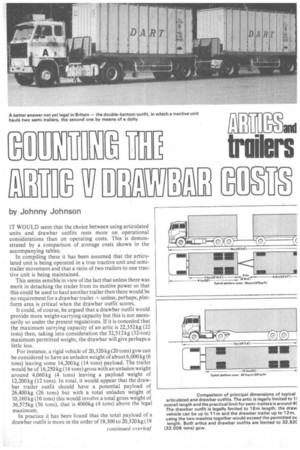

IT WOULD seem that the choice between using articulated units and drawbar outfits rests more on operational considerations than on operating costs. This is demonstrated by a comparison of average costs shown in the accompanying tables.

In compiling these it has been assumed that the articulated unit is being operated in a true tractive unit and semitrailer"movement and that a ratio of two trailers to one tractive unit is being maintained.

This seems sensible in view of the fact that unless there was merit in detaching the trailer from its motive power so that this could be used to haul another trailer then there would be no requirement for a drawbar trailer = unless, perhaps, platform area is critical when the drawbar outfit scores.

It could, of course, be argued that a drawbar outfit would provide more weight-carrying capacity but this is not necessarily so under the present regulations. If it is conceded that the maximum carrying capacity of an artic is 22,352 kg (22 tons) then, taking into consideration the 32,512 kg (32-ton) maximum permitted weight, the drawbar will give perhaps a little less.

For instance, a rigid vehicle of 20,320 kg (20 tons) gvw can be considered to have an unladen weight of about 6,000 kg (6 tons) leaving some 14,200 kg (14 tons) payload. The trailer would be of 16,250 kg (16 tons) gross with an unladen weight around 4,060 kg (4 tons) leaving a payload weight of 12,200 kg (12 tons). In total, it would appear that the drawbar trailer outfit should have a potential payload of 26,400 kg (26 tons) but with a total unladen weight of 10,160 kg (10 tons) this would involve a total gross weight of 36,575kg (36 tons), that is 4060kg (4 tons) above the legal maximum.

In practice it has been found that the total payload of a drawbar outfit is more in the order of 19,300 to 20,320 kg (19 to 20 tons) taking into account axle load restrictions.

To return to the costs. In compiling these it has also been assumed that the only standing cost factor which would be affected by the second trailer would be that of "interest". This has been calculated on an interest rate of 12 per cent on the capital cost of £2,000 for a single-axle box trailer.

So far as running costs are concerned, an amount of 0.01 p has been added for lubrication and 0.78 p has been added for tyres based on four tyres at £118 each (£472) divided bra mileage life of 60,000. An estimated 0.50 p has been included for extra maintenance, and the depreciation cost of 0.63 p is based on the cost of the trailer less tyres divided by a mileage life of 240,000.

Additional responsibility Assuming an average weekly mileage of 1000, this gives the weekly standing cost divided by 1000 plus the running cost per mile, or a total operating cost of 30.50p a mile.

The extra costs for a drawbar trailer outfit are self-explanatory though it should be noted that an extra weekly amount of £.5 has been included for wages. This is not intended to represent the cost of a mate because such staff are not now mandatory on drawbar outfits. Rather is it intended to represent an additional payment to the driver which would be reasonable in view of his additional responsibility, Thus, on the basis of a hypothetical 1000 miles a week of operation, the total operating cost works out at 30.09p a mile. Therefore for a week of operation the artic would cost £305 and the drawbar outfit £300.90 a minimal difference of £4.10.

However, the operating advantages remain quite indisputably with the drawbar outfit when straightforward trunking with local deliveries at the end is involved.

After all, to trunk with a drawbar is equivalent to completing two trunking movements in one, for both tractor vehicle and trailer are loaded with freight.

An ideal drawbar operation would be for the trailer to carry one drop so that it could be left at the consignee's premises while the rigid unit made a number of drops before picking up the trailer for return. However, such ideals are very rarely found and drivers seem to have little difficulty in using the whole outfit to make a number of drops.

In contrast, the artic tractive unit draws but the one freight-carrying semi-trailer and is assumed to be used in conjunction with another semi-trailer which it must pick up at the end of the trunk.

Probably more useful and economical than either would be the as-yet illegal "double bottom". This would add to the cost of operating an artic unit and two semi-trailers (used in turn) by the cost of the dolly say about £700 in initial cost, or about £2 a week in the standing cost interest factor and about 0.30 p a week in depreciation running cost. In terms of total operating cost, say, 0.32p a mile or about £3 a week. Extra would be the cost of the additional road fund licence.

Unfortunately the present regulations preclude an articulated vehicle drawing another trailer even if one discounts the uncertain status of the dolly under the Construction and Use Regulations.