IT 1117M JiBE

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

.■■■

TTICRLI pL LrmaNd

by George E. Toles

EN before the fuel crisis the US ivy truck industry was making an out effort to lose weight by going a high-aluminium diet, and now t vehicle fuel is both scarce and tly the higher price of light alloys I be regarded as less of a restraint their wider use.

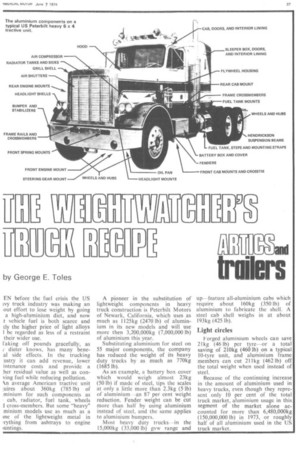

Caking off pounds gracefully, as v dieter knows, has many beneal side effects. In the trucking ustry it can add revenue, lower intenance costs and provide a her residual value as well as conving fuel while reducing pollution. kn average American tractive unit uires about 360kg (785 lb) of minium for such components as cab, radiator, fuel tank, wheels cross-members. But some "heavy" minium models use as much as a inc of the lightweight metal in Tything from ashtrays to engine luntings. A pioneer in the substitution of lightweight components in heavy truck construction is Peterbilt Motors of Newark, California, which uses as much as 1 25kg (2470 lb) of aluminium in its new models and will use more then 3,200,000kg (7,000,000 lb) of aluminium this year.

Substituting aluminium for steel on 55 major components, the company has reduced the weight of its heavy duty trucks by as much as 770kg (1685 lb).

As an example, a battery box cover which would weigh almost 23kg (50 lb) if made of steel, tips the scales at only a little more than 2.3kg (5 lb) of aluminium -an 87 per cent weight reduction. Fender weight can be cut more than half by using aluminium instead of steel, and the same applies to aluminium bumpers.

Most heavy duty trucks -in the 15,000kg (33,000 1b) gvw range and up—feature all-aluminium cabs which require about 160kg (350 lb) of aluminium to fabricate the shell. A steel cab shell weighs in at about 193kg (425 lb).

Light circles

Forged aluminium wheels can save 21kg (46 lb) per tyre--or a total saving of 210kg (460 lb) on a typical 10-tyre unit, and aluminium frame members can cut 211 kg (462 lb) off the total weight when used instead of steel.

Because of the continuing increase in the amount of aluminium used in heavy trucks, even though they represent only 10 per cent of the total truck market, aluminium usage in this segment of the market alone accounted for more than 6,480,000kg (150,000,000 lb) in 1973, or roughly half of all aluminium used in the US truck market.