Cranford farm trailers for on or off the road

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

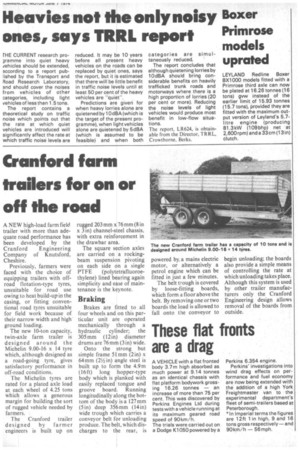

A NEW high-load farm field trailer with more than adequate road performance has been developed by the

Cranford Engineering Company of Knutsford, Cheshire.

Previously, farmers were faced with the choice of equipping trailers with offroad flotation-type tyres, unsuitable for road use owing to heat build-up.in the casing, or fitting conventional road tyres unsuitable for field work because of their narrow width and high ground loading.

The new 10-ton capacity, twin-axle farm trailer is designed around the Michelin 9.00-16 x 14 tyre which, although designed as a road-going tyre, gives satisfactory performance in off-road conditions.

The Michelin tyres are rated for a plated axle load at each wheel of 4.25 tons Which allows a generous margin for building the sort of rugged vehicle needed by farmers.

The Cranford trailer designed by farmer engineers is built up on rugged 203 mm x 76 mm (8 in x 3 in) channel-steel chassis, with extra reinforcement in the drawbar area.

The square section axles are carried on a rockingbeam suspension pivoting on each side on a single

PTFE (polytetrafluo roethylene) lined bearing again simplicity and ease of maintenance is the keynote.

Braking

Brakes are fitted to all four wheels and on this particular unit are operated mechanically through a hydraulic cylinder; the 305 mm (12in) diameter drums are 76 mm (3 in) wide.

Onto the strong but simple frame 51mm (2 in) x 64 mm (21,4 in) angle steel is built up to form the 4.9m (16ft) long hopper-type body which is planked with easily replaced tongue and groove board. Running longitudinally along the bottom of the body is a 127 mm (Sin) deep 356mm (14in) wide trough which carries a conveyor belt for unloading produce. The belt, which discharges to the rear, is

powered by, a mains electric motor, or alternatively a petrol engine which can be fitted in just a few minutes.

The belt trough is covered by loose-fitting boards, which form a floor above the belt. By removing one or two boards the load is allowed to fall onto the conveyor to begin unloading; the boards also provide a simple means of controlling the rate at which unloading takes place. Although this system is used by other trailer manufacturers only the Cranford Engineering design allows removal of the boards from outside.