Service on demand

Page 90

If you've noticed an error in this article please click here to report it so we can fix it.

• More details of the MercedesBenz Flexible Service System (FSS), reported in Workshop last October, have become available and it will be an option on the 1748LS tractive unit next year. Mercedes says that operators using FSS will be able to match their servicing requirements to the demand they make on their vehicles.

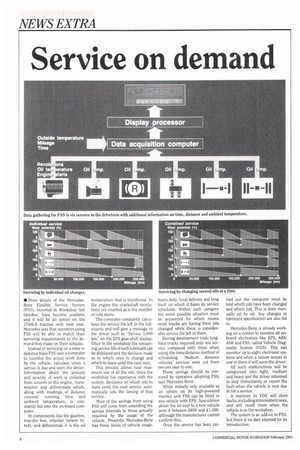

Instead of servicing on a time or distance basis FSS uses a computer to monitor the actual work done by the vehicle, calculate when a service is due and warn the driver. Information about the amount and severity of work is collected from sensors in the engine, transmission and differentials which, along with readings of distance covered, running time and ambient temperature, is constantly fed into the on-board computer.

In components like the gearbox, transfer box, retarder (where fitted), and differentials it is the oil

temperature that is monitored. In the engine the crankshaft revolutions are counted as is the number of cold starts.

The computer constantly calculates the service life left in the lubricants and will give a message to the driver such as -Service 3,000 km" on the EPS gear-shift display. Once in the workshop the remaining service life of each lubricant can be displayed and the decision made as to which ones to change and which to leave until the next visit.

This process allows near maximum use of all the oils. Once the workshop has experience with the system, decisions on which oils to leave until the next service automatically sets the timing of that service.

Most of the savings from using FSS will come from extending the service intervals to those actually required by the usage of the vehicle. Presently Mercedes-Benz has three levels of vehicle usage, heavy duty, local delivery and long haul, on which it bases its service schedules. Within each category the worst possible situation must be accounted for which means most trucks are having their oils changed while there is considerable service life left in them.

During development trials longhaul trucks required only one service compared with three when using the time/distance method of scheduling. Medium distance vehicles' services were cut from two per year to one.

These savings should be mirrored by operators adopting FSS, says Mercedes-Benz.

While initially only available as an option on its high-powered tractive unit FSS can be fitted to any vehicle with EPS. Speculation about the on-cost to a new vehicle puts it between £600 and £1,000, although the manufacturer cannot confirm this.

Once the service has been car ried out the computer must be told which oils have been changed and which not. This is done manually oil by oil. Any changes in lubricant specification are also fed in.

Mercedes-Benz is already working on a system to monitor all onboard electronics like EPS, ABS/ ASR and FSS, called Vehicle Diagnostic System (VDS). This can monitor up to eight electronic systems and when a failure occurs in one of them it will warn the driver.

All such malfunctions will be categorised into light, medium and heavy and the driver informed to stop immediately or report the fault when the vehicle is next due in for a service.

A memory in VDS will store faults, including intermittent ones, and will recall them when the vehicle is in the workshop.

The system is an add-on to FSS, but there is no date planned for its introduction.