England' s Latest Standard 6-ton Wagon.

Page 6

Page 7

If you've noticed an error in this article please click here to report it so we can fix it.

The Ripe Experience of the Yorkshire Patent Steam Wagon Company is Embodied in a New Model.

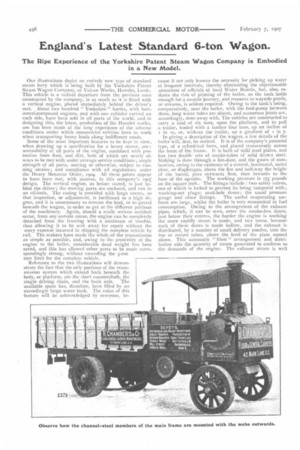

Our illustrations depict an entirely new type of standard steam lorry which is being built by the Yorkshire Patent Steam Wagon Company, of Vulcan Works, Hunslet, Leeds. This vehicle is a radical departure from the previous ones constructed by the company, in as much as it is fitted with a vertical engine, placed immediately behind the driver's seat. About two hundred " Yorkshire " lorries, with horizontal-compound engines, and with one cylinder carried on each side, have been. sold in all parts of the world, and in designing this, the latest, production of the Hunslet works, use has been made of the long experience of the adverse conditions under which commercial vehicles have to work when transporting heavy loads along indifferent roads.

Some of the most important features to be kept in view, when drawing up a specification for a heavy motor, are : accessibility of all parts of the engine, combined with protection from dust, and dirt, both of which are nearly always to be met with under average service conditions; ample strength of all parts, moving or otherwise, subject to running strains ; and compliance with all regulations under the Heavy Motorcar Order, 1904. All these points appear to have been met, with success, in this company's 1907 design. The vertical engine, as before stated, is just behind the driver; the moving parts are enclosed, and run in an oil-bath. The casing is provided with large covers, so that inspection, or adjustment, is facilitated to a high degree, and it is unnecessary to remove the load, or to grovel beneath the wagon, in order to get at the different portions of the machinery. Again, should a really serious accident occur, from any outside cause, the engine can be completely detached from the framing with a minimum of trouble, thus allowing it to be sent away for repair without the heavy expense incurred in shipping the complete vehicle by rail. The makers have made the whole of the transmission as simple as possible, and, owing to the proximity of the engine to the boiler, considerable dead weight has been saved, and this has allowed other parts to be made correspondingly strong, without exceeding the 5-ton tare limit for the complete vehicle.

Reference to the two illustrations will demonstrate the fact that the only portions of the transmission system which extend back beneath the body, or platform, are the short countershaft, the single driving chain, and the hack axle, The available space has, therefore, been filled by an exceedingly large water tank. The value of this feature will be acknowledged by everyone, be

cause it not only tesseus the necessity for picking up water aL frequent intervals, thereby eliminating the objectionable attentions of officials of local Water Boards, but, also, reduces the risk of priming of the boiler, as the tank holds enough for a 20-mile journey, and recourse to waysIde ponds, or streams, is seldom required. Owing to the tank's being, comparatively, near the boiler, with the feed-pump between them, long water tubes are absent, and numerous joints are, accordingly, done away with. The vehicles are constructed to carry a load of six tons, upon the platform, and to pull a trailer, loaded with a further four tons, up an incline of .1 in to, or, without the trailer, up a gradient of i in 7. In giving a description of the wagon, a few details of the boiler will, first, be noticed. It is of the company's patented type, of a cylindrical form, and placed transversely across the front of the frame. It is built of mild steel plates, and has two double sets of smoke-tubes of solid drawn steel. Stoking is done through a fire-door, and the gases of combustion, owing to the existence of a central, horizontal, metal plate, or diaphragm, above the fire and half-way the height of the barrel, pass outwards first, then inwards to the base of the up-take. The working pressure is 175 pounds on the square inch.. The fittings include : two safety valves, one of which is locked to prevent its being tampered with ; washing-out plugs ; mud-hole doors; the usual pressure gauge and other fittings. The useful evaporating surfaces are large, whilst the boiler is very economical in fuel consumption. Owing to the arrangement of the exhaust pipes, which, it can be seen, enter the smoke-box doors, just below their centres, the harder the engine is working the more rapidly steam is made, and vice versa, because each of these doors is made hollow, and the exhaust is distributed, by a number of small delivery nozzles, into the top or return tubes, above the level of the plate named above. This automatic " blast " arrangement and distribution aids the quantity of steam generated to conform to the demands of the engine. The exhaust steam is well superheated, thus tending to do away with visible vapour, except on very cold days, when it is impossible to avoid showing a small amount of steam from the funnel of any steam vehicle. This design of generator allows of a compact yet roomy foot plate, whilst most of the fittings can be put in a very convenient position. The feed-water is passed to the boiler by two injectors, which are placed in front of the driver's seat. The tank is fitted with strainers, and the steam water-lifter is lilted with a 3o-foot length of hose piping.

The engine is a vertical compound one, having cylinders 4.L inches and 7i inches in bore, with a piston stroke of 7i inches. Link-motion reversing gear is provided, and . all the bearing parts are case-hardened, and ground. The right-hand end of the crankshaft has a heavy fly-wheel, and an auxiliary valve enables high-pressure steam to be admitted to both cylinders, to give additional power when starting the wagon on a hill, or upon soft ground. The gears, those on the crankshaft as well as on the secondmotion shaft, are of cast steel, those for the high speed being machine cut, whilst the ratios are, respectively, three and six miles per hour. The crankshaft has a diameter of 21 inches, whilst the second-motion shaft is 3 inches in diameter. A Hans Renold roller chain transmits the power, from a central chain wheel carried, between the two spur wheels, on the short second-motion shaft, to the differential gearing upon the back axle; this axle is 41 inches in diameter, and is of the best grade of Yorkshire iron. The differential gearing is of the bevel pinion type, and is of very strong and heavy construction. The radius rods are of mild steel, and have long, adjustable, sleeve nuts.

The front axle, which is a steel forging, is supported by a transverse laminated spring, and is free to rock, thus allowing the front wheels to move over obstacles with ease; the vehicle, owing to this design, is carried upon a threepoint suspension. The details of the steering mechanism are well thought out, and all pins, and joints, are suitably case-hardened. The journals upon which the front, and back, wheels revolve are hardened, and ground, and the hubs are provided with long phosphor-bronze bushes. The framework is constructed of channel steel, having a section of 6 inches, by 3 inches, by inch, and it will be noticed that the open side of the section faces outwards ; this disposition has been adopted so that the bolts, by which the springs, radius rods, and other parts are attached to the main side members, are very accessible for examination, or tightening, should this be necessary. The cross members of the frame are, also, channel steel, but of a slightly less section, and these are connected to the main frame members by angle plates, and gusset pieces, whilst all the rivets are closed when hot. The company has paid much attention to the framework, as its years of experience have shown that, no matter how good is the workmanship, and material, put into the transmission system of a vehicle, the repair bill, unless the frame is calculated to stand the vibration and strains set up by travelling over rough roads, will, most certainly, be considerably increased, and a corresponding reduction in profits will have to be encountered. The springs are of the usual semi-elliptic pattern, and the back ones slide in brackets, which are fitted with grease cups : the front spring is, as mentioned before, placed in a lon gitudinal position over the front axle, and is held at its centre by a bridle piece; its ends bear upon the axle between the

two horn-plates, which allow for the vertically-reciproeatino action of the axle. The wheels are of the artillery type, an'-d are constructed from the best quality of winter-felled timber;

the front wheels are 3 feet in diameter, and 5 inches on the tread, whilst the back ones are 3 feet 3 inches in diameter, and have a tread of icq inches. Steel wheels will be supplied, to order, if desired. The brakes are powerful, and the connecting rods, and joints, are made with a high factor of safety. The back brake is of the screw down block pattern, whilst a second

one, of the band type, will hold the vehicle,fully loaded, upon any reasonable gradient. The reversing gear upon the en gine can, also, be used as a brake if desired, although the too sudden use of this is rather to be deprecated. Very neat provision for applying a trailer brake, as fitted to a 6-ton wag-on of Marriage, Neave and Company, Limited, has been devised by the makers.

The bodies will be built to any purchaser's requirements, but the one which is recommended, having a flat table, is constructed of best red pine, framed with oak, and is 13 feet long by 6 feet 6 inches in width. The cab over the driver is supported, at the back, by four stout uprights, whilst the front end rests upon two steel rods which are bolted to the top of the boiler shell.

The approximate dimensions of the vehicle are : overall length, 19 feet ; overall width, 6 feet 6 inches; wheel base, feet 9 inches; width over edge of tire, 6 feet ; and height over chimney, 9 feet. The tare weight is 4 tons 19 cwt.

The company will send a competent driver with a wagon, when it is purchased, free of wage charges, so that the future driver can get a thorough grasp of the manner in which the boiler, engine, and vehicle generally, should be handled. The outfit consists of head and tail lamps, gauge lamps, firing tools, screw jack, and a tube expander. This last-named article, by the way, is rather a dangerous tool to give into the charge of a " raw" hand, as much harm can be done to a boiler by its injudicious use. Oil cans and feeders, spanners, etc., are, also, included in the kit.

The company guarantees that every part of the wagon is built of the highest possible grade of material, and, in each case, of that most suitable for any particular part, and will, within four months from the time of purchase, replace any portion that may be broken, if any such breakage is due to defective material.