Eaton double 'H' debut

Page 24

If you've noticed an error in this article please click here to report it so we can fix it.

EATON's 7200 Series transmission which is to be introduced at Frankfurt in September (CM June 29) will be fitted as standard with the double "H" control system for the range change. It is now being offered as an option on the 9500 and 12500 series.

Increasing demand for sim plified gear selection prompted Eaton to develop its system. Instead of using the usual separate pneumatic switch, range selection is carried out automatically as the gear lever is moved over a detent.

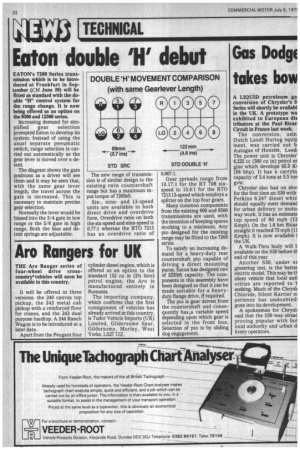

The diagram shows the gate positions as a driver will see them and it may be seen that, with the same gear lever length, the travel across the gate is increased. This is necessary to maintain precise gear selection.

Normally the lever would be biased into the 3/4 gate in low range or the 5/6 gate in high range. Both the bias and detent springs are adjustable. The new range of transmission is of similar design to the existing twin countershaft range but has a maximum input torque of 7201bft.

Six-, nineand 13-speed units are available in both direct drive and overdrive form. Overdrive ratio on both the six-speed and nine-speed is 0.77:1 whereas the RTO 7213 has an overdrive ratio of 0.867:1.

Gear spreads range from 10.17:1 for the RT 706 sixspeed to 15.4:1 for the RTO 7213 13-speed which employs a splitter on the top four gears.

Many common components from the existing 600 and 9500 transmissions are used, with the intention of keeping spares stocking to a minimum. Any pto designed for the existing range may be fitted to the 7200 series.

To satisfy an increasing demand for a heavy-duty rear countershaft pto capable of driving a direct mounting pump, Eaton has designed one of 3251bft capacity. The components in this assembly have been designed so that it can be made suitable for a heavyduty flange drive, if required.

The pto is gear driven from the countershaft and consequently has .a variable speed depending upon which gear is selected in the front box. Selection of pto is by sliding dog engagement.