For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN ShILLIIVOS is awarded sack week to the sender of the best letter which we publish on this page; all others are paid for at the rate of a pemy a lane, with an allowance for photographs. All notes are edited before being published, Mention pour employer's name, in confidence, as evidence of good faith. Address, D., M. and F„, "The Commercial Motor," 7-15, Rosebery Avenue, London, E.G. 1.

Lamps Alight.

On Saturday, August 9th, light your lamps at 9.4 in London, 10.12 in. Edinburgh, 9.32 in Newcastle, 9.32 in Liverpool, 9.21 in Birmingham, 9.42 in Bristol, and 10.15 in Dublin.

A Finicking Boiler Repair.

The sender of the following communication has been awarded the 10s. prize this week.

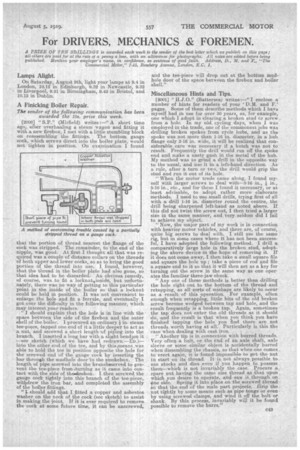

[2000] " S.P.'' (Mirfield) writes :—" A short time, ago, after overhauling a steam wagon and fitting it with a, new firebox, I met with a little stumbling block on reassembling the fittings. The bottom gauge cock, which screws direct into the boiler plate, would not tighten in position. On examination I found

that the portion of thread nearest the flange of the cock was stripped. The remainder, to the end of the

was good. At first I thought all that was required was a couple of distance collars on the threads of both upper and lower cocks, so as to bring the good portion of the thread into use. I found, however, that the thread in the boiler plate had also gone, so that idea had to be discarded. An obvious remedy, of coarse, was to fit a locknutlinside, but unfortunately, there was no way. of getting to this particular point in the inside of the boiler so that a locknut could be held in position. It was not convenient to enlarge the hole and fit a ferrule, and eventually got.over the difficulty in the following manner, which may interest your readers.

"I should explain that the hole is in line with the space between the side of the firebox and the outer shell of the boiler. I procured an ordinary .1 in. steam tee-piece, tapped one end of it a little deeper to act as a nut, and screwed a short length ofpiping into the branch. I inserted a long bar with a slight bendion it —see sketch (which we, have had redrawn.—ED.)— into the other end of the tee, and by thisimeana,was able to hold the tee in position opposite the hole for the screwed end of the gauge cock by inserting the bar through the mudhole door 'in the smokebo*. The length of pipe screwed into the branchesserved tk) prevent the tee-piece from .turning as it came into contact with the side of the..firebox. I then •screwed the gauge cock tiKlitly into this branch of the tee-piece, withdrew the iron bar, and completed the assembly of the boiler fittings.

"I should add that I fitted a. copper and asbestos washer on the neck of the cock (see sketch) to assist in making the joint. If it is ever required to remove the cock at some future time, it can be unscrewed, and the tee-piece will drop out at the bottom mudhole door of the space between the firebox and boiler shell."

Miscellaneous Hints and Tips.

[2001] " H.J.0." (Battersea) writes:—" I enclose a number of hints for readers of your 'D.A.. and F.' pages. Some of them describe methods which I have myself had in use for over 30 years, as, for example, one which I adopt in clearing a broken stud or screw from a hole. In my old cycling days, when I was employed in the trade, one of the commonest jobs was drilling broken spokes from cycle hubs, and as the spoke was not more than 1-16 in. diameter, in a hub flange only 3-16 in. wide, it will be realized that considerable care was necessary if a botch was not to result. Frequently the drill would run off the spoke end and make a nasty; gash in the metal of the hub. My method was to grind a drill in the opposite way to the 'usual, and use it in a left-hand direction. As a rule, after a turn or two, the drill would grip the stud and run it out of its hole.

"When the motor trade came" along, I found myself with larger screws to deal with-3-16 in., 5-16 in.' etc., and for these found it necessary, or at least advisable, to adopt rather more elaborate methods. I used to use small drills, trying first of all with a drill 1-16 in. diameter round the centre, the drill being sharpened left-hand as noted above. If this did not twist the screw out, I then tried a larger size in the same manner, and very seldom did I fail to achieve my object. "Now, the major part of my work is in connection with heavier motor vehicles, and there are, of course, quite big screws to deal with. I still use the same rig, but in Some cases where it has not been successful, I have adopted the following method. I drill a comparatively large hole in the broken stud, adopting the above device in the hope of removing it. If it does not come away, I then take a small square file

and square the hole ; take a piece of rod and file a square end to it so that it will then act as a key for turning out the screw in the same way as one operates the familiar three-jaw chuck.

"Any one of these methods is better than drilling the hole right out to. the bottom of the thread and retapping, as all sorts of mishaps are likely to occur as a result of this ;operation. For example, often enough when retappmg, little bits of the old broken screw become wedged -between tap and hole, and the result frequently is a broken tap. Again, sometimes the tap does not enter the old threads as it should 'do, and the result is that when you think you have finished tapping the hole you find there are not threads worth having at all. Particularly is this the case when dealing with east iron. "Another tip is in connection with burred threads. Very often a bolt, or the end of an axle shaft, axle sleeve or some similar object is accidentally burred when dissembling the chaasis, so that when one comes. to erect again, it is found impossible to get -the nut to start on its thread. It is not always possible to. use stocks and dies even if you happen to possess them—which is not invariably, the case. . Procure a. spare nut having the same size, thread as that upon.. which you desire to operate, and saw it through on .ane side. Spring it into place on the screwed thread o that the end of the male part projects. Grip the. nut tightly by some means such as pipe tongs or even by using screwed clamps, and wind it off the bolt or shank. By this process, invariably will it be. fonncl possible to remove the burrs."