FORD VAN POINTERS.

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

By R. T. Nicholson (Author of "The Book of the Ford").

NOW LET US get a little deeper into the subject. Up to now, I have been'clealing. mainly with easy jobs pretty regularly called for. I am now going to deal with bigger jobs, not often called for.

"Am I up to these big jobs? ',.you ask. I cannot tell you. If you have some mechanical gumption— if your fingers are not all thumbs—if you can use simple tools—you ought to be able to do these bigger jobs. It is not nso much a question of actually doing them as of knowing how ; and it is my job to tell you how : that is what I Am going to do, taking it for granted that you are not' a born mechanical fool, that you are a reasonablyhandy sort of person, and that you can use a wrench, pincers, hammer, screwdriver, and tools of that simple sort., Here goes.

125.—Taking Up the Bands.

This is a pretty simple job—hardly below the surface. It is needed whenever pressure on a pedal does not produce the desired result—whether it is a matter of picking up slow speed, or reversing, or braking. If pressure on a pedal gives weak results, or causes chattering, the remedy is usually to be found in taking up the band (though this will not do the trick in all circumstances, as the band may want relining, or the trouble may lie still deeper. I shall deal with relining later on).

126.--Foot Brake.

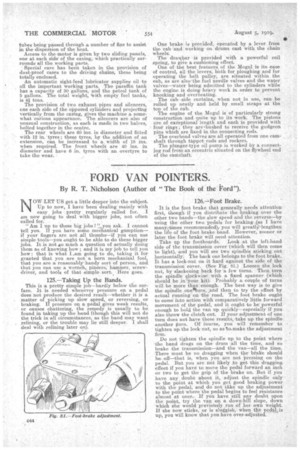

It is the foot brake that generally needs attention' first, though if you distribute the braking over the other two bands—the slow .speed and the reverse—by using the other two pedals for braking ,(as I have manyttimes recommended); you will greatly lengthen the life of the foot brake band. However, sooner or later the foot brake will need attention. Take up the footboards. Look at the left-hand side of the transmission cover (which will then come to light), and you will see two spindles sticking out horizontally: The back one belongs to the foot brake. It has a lock-nut on it hard against the side of the transmission cover. (See Fig. 81.) Loosen the lock nut, by slackening back for 'a few turns. Then turn the spindle ,glockwise with a fixed spanner (which . should be in 'Your kit). Probably a couple of turns will be more than enough. The best way is to give the spindle onesturn, ,and then to try the effect by actual running on the road. The foot brake ought to come into action with comparatively little forward movement of the pedal, and it ought to be powerful enough to hold the van up quickly—especially if y.ou also throw the clutch out. If your adjustment of one turn does not have these results,.take -up the spindle another turn. Of Course, you will remember to tighten up. the lock nut, so as too-nake the adjustment firm..

Do not tighten the spindle up to the point where the band drags on the drum all the time, and so brake the transmission—and the van—all the time. There must be no dragging when the bake should beoff—that is, when you are not pressing on the pedal. But you are not likely ,to get this dragging. effect if you have to move the pedal forward an inch or two to get the grip of the brake on. But if you have any doubt about it, adjust the spindle only to the point at which you get good braking power with the pedal, and do not •thke up the adjustment to the point where the pedal begins to feel resistance almost at once. If you have still any doubt upon the point, try the van on a down-hill slope, down which she would wevidusly run of her own weight. If she now sticks, or is sluggish,when the pedat is up, you will know that you have over-adjusted.

127.—Clutch.

Your clutch calls for adjustment whenever tne transmission slips under load—for instance, in picking 'up the high speed from slow, -or in climbing hills. When your high speed is right home, there should be no slip in any circumstances : the clutch ought then

to be quite positive, and not slithery. .

The adjustment of the clutch is rather finicking. It needs care in several respects.

Take your transmission cover door off, as before, as shown in Fig. 82: A clutch finger will now come into view. There are three such clutch fingers. In Fig. 82 the adjusting screw in one of these three clutch fingers is being turned. As the engine turns, with the clutch in these three fingers turn with the transmission and, with the engine. When the clutch is out, the fingers do not turn. YOU can bring all three fingers into sight if you ,will first jack up one back wheel, and put tho brake lever into forward position, and then get Somebody to turn the starting handle slowly. (Unless you so jack up, the starting handle cannot, of course, be turned.)

In each clutch finger is a set screw at its top end. The object of this set screw is to regulate the amount of movement of the clutch finger at the opposite end. The farther the screw is set in, the more positive does the clutch become. On the other hand, if the screw is set too far in, the clutch will not be free when it should be—when the hand-brake lever is right back, or when it is in neutral, or when the clutch pedal is depressed. Therefore the set screws must be rightly adjusted, to secure positive action of the clutch on the one hand, and its freedom on the other.

The adjustment of the set screws is necessary to compensate for wear on the clutch plates. As these wear thinner in use, the set screws must be turned farther in. In the very long run, there is a limit to the set screw adjustment, and it becomes better to add an extra clutch plate : that, however, is another story. A clutch 'Will take a lot of adjustment during a good many years, before it becomes necessary to insert another plate.

Bring one of the clutch fingers to such a point that you can use a screwdriver on its set screw. The most convenient position is when the screw is at the highest possible point. You can get it there by throwing the hand brake lever right forward, and then, getting somebody to turn the starting handle, stopping when you say " Stop!" Use a rather short, broad-bladed screwdriver, and tie it up with a piece of string, as recommended earlier.

Through the set screw a split pin passes. Your first job is to remove the split pin. Now do be careful, or you will be in trouble. Bend the legs straight, and see that they do not break off. If they do break off, do not let any bits fall into the 'transmission. Through the eye of the split pin pass as big a piece of wire as -will go—Bowden cable preferred--and then pull out the split pin with the wire. That method makes it sure that you will not let the split pin fall into the transmission.

You can now turn the set screw. How much'? If the slipping of the clutch has been very bad, give it a full turn : if it has only been slight, give it half a turn. Turn clockwise—the regular way in which you turn a screw home. Replace split pin, bend the legs back, and mark the part in some _way so that you will know that you have adjusted it : tie it round with a small piece of string, or dab it with paint,. Then get the engine turned by the starting handle till another set screw comes upper-Most_ Treat that exactly in the same way. Whatever amount of turn you gave to the first set screw you must give to this one : if it was a half-turn, give this a halt-turn: if it was a whole turn, give it a whole turn. Insert split pin, mark, and then have the third finger brought up. 'Treat that in exactly the same way.

The reason why I told you to mark each finger as adjiiste,c1 was that you might know which had been

adjusted. Sometimes, when the starting handle is turned, it is turned too quickly, and then the set screws rush by, and you lose count; and do not know which one has been adjusted, unless you mark it somehow. And it-is of the greatest importance that each set ,screw should be taken up to exactly the same amount—that' is, with the same amount-'of "turning. Otherwise the clutch will not work under even pressure, but will get it all on one side. I have known much damage done by overturning one set screw, as-id hot turning one of the others at all.

And do be sure not to drop split pins, whole or in parts, into the transmission. In inserting, it is best to pass. a length of string' through the eye of the new set screws, so that if it slips from your fingers (and split pins are easily dropped—particularly when oily), you can recover it. Finally, use new split pins after adjustment. Do not put the old ones back, even if you can. They will probably'break off later if you do, and you Must positively have no stray metal in that transmission. If it does nothing worse, it cap short-circuit the magneto • and you do not want that. You need not, by the way; have help in turning the starting handle if you will mark the fingers as adjusted. You can go from the transmission to the

starting, handle and turn—though you cannot see what you are doing as regards moving the 'fingers -when you are there. You can, however, judge, and it does not,matter if you overturn the starting handle 'if you are quite sure which finger has been adjusted : you can go on turning till the finger that, you want to attack comes uppermost again. It is much more convenient, however, to have help. I will,finally say that there. is one good test as to whether you have got your clutch finger screws too tight. When the hand brake lever is pulled back, all the clutch fingers ought to ,be quite free—that is to say, you ought to be able to 'move these fingers with your fingers forward and backwards slightly. If you put the hand 'brake lever hard forward, you will (or should) find that they are no longer free you stiff 111 engagement. Now, whileetheir stiffness -when the clutch is in, is,no guide as to the proper stiffness,

of the set screws, their looseness when the hand trake lever is hard baclois a guide as to •tha,set screws not being too far in. So longats the fingers are free when thellaand brake is on, that indicates that. the clutch is really out—as it should be. If you have got the set screws too far in, you would find that thefingers would not get free, and that 'thus the clutch would not he really free. The only test of the effectiveness of the clutch, however, is, as before, trial on th.e road.