THE FORD ONE-TON CHASSIS.

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

A Design which Incorporates the Weil-known Ford Power and Gear Unit.

VOR YEARS the poor Ford has had to suffer in ailence whilst numerous attempts were made by interested per. sons, other than its manufacturers, to convert it into a lorry. Some of the converters produced reflected credit on the ingenuity of their inventors, and are doing useful work, but others were hopeless from the commencement. The most successful type is that in which another practically complete frame is bolted to the existing Ford frame. In nearly every type the existing Ford bevel drive and differential gearing have been retained, and therein lie the weak points.

Some few months ago the Ford Co. decided to take the bull by the horns and meet the demand for a cheap and serviceable chassis to carry loads up to one ton by making a chassis themselves, using the • standard Ford power and changtespeed gear unit, combined with a, lorry frame and a heavier axle. This model is called the Ford Model " T" one-ton truck.

The frame of this vehicle is of pressed channel-sectioned steel, tapered to the front and rear, and of fle in. thickness. It allows for a wheelbase of 124 ins., and the chassis will turn in a 46 ft. circle.

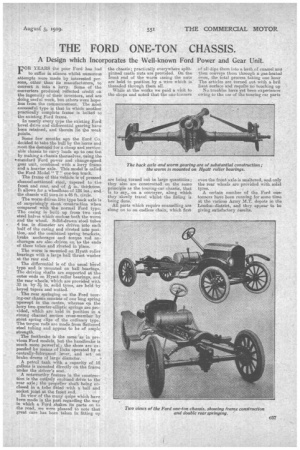

The evorm.driven live type back axle is of surprisingly stout construction when compared with the normal Ford type. The casing is built, up from two east steel halves which enclose both the worm and the wheel. Solid-drawn steel tubes 4 ins, in diameter are driven into each half of the casing and riveted into position, and the combined spring brackets, ',rake anchorages and torque rod anchorages are also_ driven an to. the ends of these tubes and riveted in 'place. .

The worm is mounted on Hyatt roller bearings with a large ball thrust washer at the rear end.

The differential is of the usual bevel type and is mounted on ball bearings. The driving shafts are supported at the outer ends on Hyatt roller bearings, and the rear wheels, which are provided with 32 in. by 3i in. solid tyres, are held by keyed tapers and nutted.

The rear springing on the Ford touring-ear chassis consists of one long spring upswept in the centre, whereas on the lorry two quarter-elliptic epriegs are iprosided, which are held in position n a strong channel section cross-member by stout spring clips of the ordinary type. The torque rods are made from flattened steel tubing and appear to be of ample strength. The footbrake is the same as in previoni Ford models, but the handbrake is much more powerful ; the shoes are expanded by means of links operated by a centrally-fulerumed lever, and act on brake drums of large diameter. A petrol tank with a capacity of 10 gallons is mounted directly on the frame under the driver's seat.

A noteworthyfeature in the construction is the entirely enclosed drive to the rear axle; the propeller shaft being enclosed in a tube fitted with a ball and

socket joint at the front end. •

In view of the many quips which have teen made in the past regarding the way in which a Ford shakes its parts on to the road, we were pleased to note that great care has been taken in fitting up

the chassis; practically everywhere splitpinned castle nuts are provided. On the front end of the worm casing the nuts are held in position by a wire which is threaded through them all. While at the Works we paid a visit to the shops and noted that the ene-tonners

are being turned out in large quantities; they also are constructed on the same principle as the touring-ear chassis, that is to say, on a conveyer, along which they slowly travel whilst the fitting is being done.

All parts which require enamelling are slung on to an endless chain, which first

of all dips them into a bath ,of enamel ana then conveys them through a gas-heated oven, the total process taking one hour The articles are turned out with a bril liant surface and require no touching up No troubles have yet been experience( owing to the use of the touring car parts

even the front axle is unaltered, and only the rear wheels are provided with.solid tyres.

A certain number of the Ford onetonners have been running for some time at the various Army .M.T. depots in the London, district, and they appear to be giving satisfactory results.