Anyone connected with road transport who hasn't heard of

Page 40

Page 42

Page 43

Page 44

Page 45

Page 46

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

the Renault AE has either been visiting relations off-planet or is dead.

Following the ballyhoo over Renault's futuristic towering tractor it inevitably stole the show at the NEC — the queue of operators waiting to climb into the cab would have done justice to the local Roxy on a wet Saturday night.

Born out of Renault's Virages concept tractor (featured by CM back in 1985) AE prototypes unconvincingly camouflaged in olive drab have been trundling around the Continent and the UK for several months now. The finished product has been well worth waiting for.

For once marketing claims like "revolutionary" and "trend setting", which we usually take with a healthy pinch of salt, are fully justified because the AE takes traditional tractive unit design and stands it on its head. While other manufacturers have been agonising over how to make their artics smaller and less conspicuous, Renault has come up with a tractor that stands head and shoulders above the crowd at an awesome 3.77 metres.

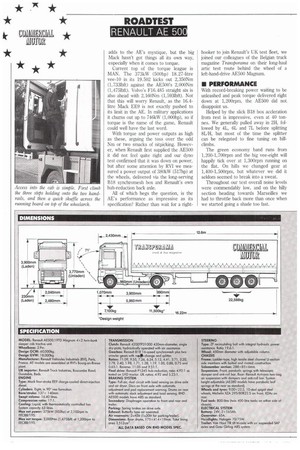

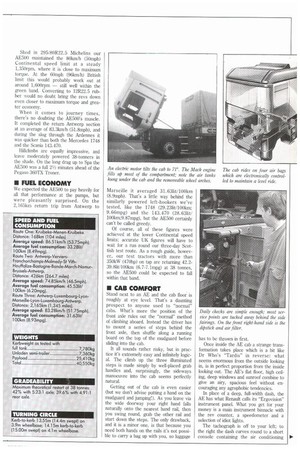

Renault has not bucked the environmentally friendly trend just for the hell of it. Its cab has been made completely separate from the driveline, which sits in its own encapsulated pocket within the chassis. This obviously facilitates thermal and acoustic insulation. More importantly, it finally gives drivers a flat floor to move around on: no engine hump, no transmission tunnel, just 2. 72m2 of unobstructed floorspace and a 1.87m ceiling height. If you haven't yet been metricated, that means that a strapping six-footer will be able to walk around without ducking.

The cab is suspended on four air bags with dampers and is attached to the chassis, (or "technical module" as Renault likes to call it) by two panhard rods and an anti-roll bar at the front and a reaction rod at the rear. Three levelling valves (one at each front corner, one at the rear) constantly adjust the air pressure to keep the cab level under all load and road conditions. Reaction time will vary with the load, but is said to average only a couple of seconds.

New cab, new construction. More than 60% of the body panels used on the AE Integrale cab are made from composite materials hung on a steel subframe. Only the rear cab panel and floor pan are conventional steel pressings.

The height of the cab makes roof deflectors redundant; its shape has been designed to smooth the air flow past a fullheight semi-trailer.

Like typical American forward-control tractors, the AE's steered axle is placed well to the fore. Renault says that this improves road holding and prevents cars from becoming wedged under the cab in the event of a front-end collision. Which is nice to know if you're planning to drive into the front of an AE.

More surprises lie in wait below that flat floor, but they are unlikely to offend even the most conservative operators.

• DRII/ELINE

The Ali comes with two engine options: the familiar 275kW (375hp) 12-litre Renault straight six, from the R range; and a fire-breathing vee-eight rated at 375kW (503hp) courtesy of US truck manufacturer Mack, which seems destined to become a wholly owned subsidiary of Renault.

Being the first European production-line artic to break the 500hp barrier obviously adds to the AE's mystique, but the big Mack hasn't got things all its own way, especially when it comes to torque.

Current top of the torque league is MAN. The 373kW (500hp) 18.27-litre vee-10 in its 19.502 kicks out 2,350Nm (1,7331bft) against the AE500's 2,000Nm (1,4751bft). Volvo's F16,485 straight six is also ahead with 2,160Nm (1,5931bft). Not that this will worry Renault, as the 16.4litre Mack EE9 is not exactly pushed to its limit in the AE. In military applications it churns out up to 746kW (1,000hp), so if torque is the name of the game, Renault could well have the last word.

With torque and power outputs as high as these, arguing the toss over the odd Nm or two smacks of nitpicking. However, when Renault first supplied the AE500 it did not feel quite right and our dyno test confirmed that it was down on power, but after some attention by RVI we measured a power output of 380kW (517hp) at the wheels, delivered via the long-serving B18 synchromesh box and Renault's own hub-reduction back axle.

All of which begs the question, is the AE's performance as impressive as its specification? Rather than wait for a right hooker to join Renault's UK test fleet, we joined our colleagues of the Belgian truck magazine Transporama on their long-haul artic test route behind the wheel of a left-hand-drive AE500 Magnum.

• PERFORMANCE

With record-breaking power waiting to be unleashed and peak torque delivered right down at 1,200rpm, the AE500 did not disappoint us.

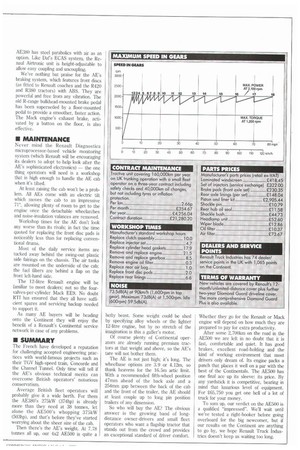

Helped by the slick B18 box accleration from rest is impressive, even at 40 tonnes. We generally pulled away in 2H, followed by 4L, 6L and 7L before splitting 8L/H, but most of the time the splitter can be relegated to fine tuning on hillclimbs.

The green economy band runs from 1,2001,700rpin and the big vee-eight will happily tick over at 1,300rpm running on the flat. On hills we changed gear at 1,400-1,500rpm, but whatever we did it seldom seemed to break into a sweat.

Throughout our test overall noise levels were commendably low, and on the hilly section heading towards Marseilles we had to throttle back more than once when we started going a shade too fast.

Shod in 295/80R22.5 Michelins our AE500 maintained the 801un/h (50mph) Continental speed limit at a steady 1,350rpm, where it is close to maximum torque. At the 60mph (96km/h) British limit this would probably work out at around 1,600rpm — still well within the green band. Converting to 12R22.5 rubber would no doubt bring the revs down even closer to maximum torque and greater economy.

When it comes to journey times, there's no doubting the AE500's muscle. It completed the return Antwerp section at an average of 83.3kmill (51.8mph), and during the slog through the Ardennes it was quicker than both the Mercedes 1748 and the Scania 143.470.

Ifillclimbs are equally impressive, and leave moderately powered 38-tonners in the shade. On the long drag up to Spa the AE500 was a full 21/2 minutes ahead of the Pegaso 360TX 'ironer.

II FUEL ECONOMY

We expected the AE500 to pay heavily for all that performance at the pumps, but were pleasantly surprised. On the 2,165km return trip from Antwerp to Marseille it averaged 31.631it/100km (8.9mph). That's a little way behind the similarly powered left-hookers we've tested, like the 1748 (29.231it/100km; 9.66mpg) and the 143.470 (28.63111/ 100km;9.87mpg), but the AE500 certainly can't be called greedy.

Of course, all of these figures were achieved at the lower Continental speed limits; accurate UK figures will have to wait for a run round our three-day Scotfish test route. As a rough guide, however, our test tractors with more than 350kW (470hp) on tap are returning 42.239.8lit/100km (6.7-7.1mpg) at 38 tonnes, so the AE500 could be expected to fall within that band.

• CAB COMFORT

Stand next to an AE and the cab floor is roughly at eye level. That's a daunting prospect to anyone used to "normal" cabs. What's more the position of the front axle rules out the "normal" method of climbing aboard. Instead the driver has to mount a series of steps behind the front axle, then shuffle along a running board on the top of the mudguard before sliding into the cab.

It all sounds rather risky, but in practice it's extremely easy and infinitely logical. The climb up the three illuminated steps is made simply by well-placed grab handles and, surprisingly, the sideways manoeuvre into the cab seems perfectly natural.

Getting out of the cab is even easier (but we don't advise putting a hand on the mudguard and jumping!). As you leave via the wide doorway your right hand falls naturally onto the nearest hand rail, then you swing round, grab the other rail and start down the steps. The only drawback, and it is a minor one, is that because you need both hands on the rails it's not possible to carry a bag up with you, so luggage has to be thrown in first.

Once inside the AE cab a strange transformation takes place which is a bit like Dr Who's "Tardis" in reverse: what seems enormous from the outside looking in, is in perfect proportion from the inside looking out. The AE's flat floor, high ceiling, deep windows and sunroof combine to give an airy, spacious feel without encouraging any agrophobic tendencies.

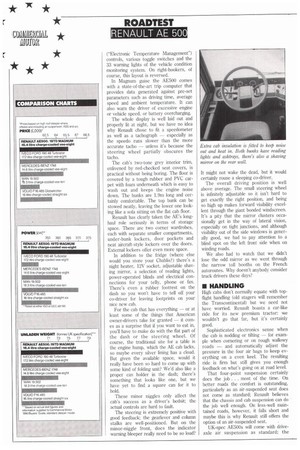

In place of a deep, full-width dash, the AE has what Renault calls its "Ergovision" instrument panel. What you get for your money is a main instrument binnacle with the rev counter, a speedometer and a selection of idiot lights.

The tachograph is off to your left; to the right the dash curves round to a short console containing the air conditioning •

("Electronic Temperature Nlanagement") controls, various toggle switches and the 33 warning lights of the vehicle condition monitoring system. On right-hookers, of course, this layout is reversed.

In Magnum guise the AE500 comes with a state-of-the-art trip computer that provides data generated against pre-set parameters such as driving time, average speed and ambient temperature. It can also warn the driver of excessive engine or vehicle speed, or battery overcharging.

The whole display is well laid out and properly lit at night, but we have no idea why Renault chose to fit a speedometer as well as a tachograph — especially as the speedo runs slower than the more accurate tacho — unless it's because the steering wheel partially obscures the tacho.

The cab's two-tone grey interior trim, enlivened by red-checked seat covers, is practical without being boring. The floor is covered by a tough rubber and PVC carpet with foam underneath which is easy to wash out and keeps the engine noise down. The bunks are 1.9m long and certainly comfortable. The top bunk can be stowed neatly, leaving the lower one looking like a sofa sitting on the flat cab floor.

Renault has clearly taken the AE's longhaul role seriously in terms of storage space. There are two corner wardrobes, each with separate smaller compartments, under-bunk lockers, door pockets and neat aircraft-style lockers over the doors. External lockers offer even more space.

In addition to the fridge (where else would you store your Chablis?) there's a night heater, 12V socket, adjustable shaving mirror, a selection of reading lights, power-operated blinds and electrical connections for your telly, phone or fax. There's even a rubber footrest on the dash so you won't have to tell off your co-driver for leaving footprints on your nice new cab.

For the cab that has everything — or at least some of the things that American owner-drivers take for granted — it comes as a surprise that if you want to eat in, you'll have to make do with the flat part of the dash or the steering wheel. Of course, the traditional site for a table is the engine hump, which the AE cab lacks, so maybe every silver lining has a cloud. But given the available space, would it really have been so hard to come up with some kind of folding unit? We'd also like a proper can holder in the dash; there's something that looks like one, but we have yet to find a square can for it to hold.

These minor niggles only affect the cab's success as a driver's bedsit; the actual controls are hard to fault.

The steering is extremely positive with good feedback; the gearlever and column stalks are well-positioned. But on the minor-niggle front, does the indicator warning bleeper really need to be so loud? It might not wake the dead, but it would certainly rouse a sleeping co-driver.

The overall driving position is well above average. The small steering wheel is infinitely adjustable so it isn't hard to get exactly the right position, and being so high up makes forward visibility excellent through the giant bonded windscreen. It's a pity that the mirror clusters occasionally get in the way of lateral vision, especially on tight junctions, and although visibility out of the side windows is generally good, we had to pay attention to a blind spot on the left front side when on winding roads.

We also had to watch that we didn't lose the odd mirror as we went through the narrow toll booths on the French autoroutes. Why doesn't anybody consider truck drivers these days?

• HANDLING

High cabs don't normally equate with topflight handling (old stagers will remember the Transcontinental) but we need not have worried. Renault boasts a car-like ride for its new premium tractor: we wouldn't go that far, but it's certainly good.

Sophisticated electronics sense when the cab is nodding or tilting — for example when cornering or on rough wallowy roads — and automatically adjust the pressure in the four air bags to keep everything on a even keel. The resulting ride is firm but still gives you enough feedback on what's going on at road level.

That four-point suspension certainly does the job . . most of the time. On better roads the comfort is outstanding, particularly as an air-suspended seat does not come as standard; Renault believes that the chassis and cab suspension can do the job well enough. On less-well maintained roads, however, it falls short and maybe this is why Renault still offers the option of an air-suspended seat.

UK-spec AE500s will come with driveaxle air suspension as standard; the AE380 has steel parabolics with air as an option. Like Dafs ECAS system, the Renaul Airtronic unit is height-adjustable to allow easy coupling and uncoupling.

We've nothing but praise for the AE's braking system, which features front discs (as fitted to Renault coaches and the R420 and R380 tractors) with ABS. They are powerful and free from any vibration. The old R-range bulkhead-mounted brake pedal has been superseded by a floor-mounted pedal to provide a smoother, faster action. The Mack engine's exhaust brake, activated by a button on the floor, is also effective.

• MAINTENANCE

Never mind the Renault Diagnostica microprocessor-based vehicle monitoring system (which Renault will be encouraging its dealers to adopt to help look after the AE's sophisticated electronics) — the one thing operators will need is a workshop that is high enough to handle the AE cab when it's tilted.

At least raising the cab won't be a problem. All AEs come with an electric tilt which moves the cab to an impressive 710, allowing plenty of room to get to the engine once the detachable wheelarches and noise-insulation valances are removed.

Workshop times for the AE don't look any worse than its rivals; in fact the time quoted for replacing the front disc pads is noticeably less than for replacing conventional drums.

Most of the daily service items are tucked away behind the swing-out plastic side fairings on the chassis. The air tanks are mounted on the underside of the cab; the fuel filters are behind a flap on the front left-hand side.

The 12-litre Renault engine will be familiar to most dealers; not so the fourvalves-per-cylinder Mack EE9. No doubt RTI has ensured that they all have sufficient spares and servicing backup needed to support it.

As many AE buyers will be heading onto the Continent they will enjoy the benefit of a Renault's Continental service network in case of any problems.

• SUMMARY

The French have developed a reputation for challenging accepted engineering practices with world-famous projects such as their TGV high-speed train, Concorde and the Channel Tunnel. Only time will tell if the AE's obvious technical merits can overcome British operators' notorious conservatism.

Average British fleet operators will probably give it a wide berth. For them the AE380's 275kW (374hp) is already more than they need at 38 tonnes, let alone the AE500's whopping 375kW (503hp), and that's before they've started worrying about the sheer size of the cab.

Then there's the AE's weight. At 7.78 tonnes all up, our 4x2 AE500 is quite a hefty beast. Some weight could be shed by specifying alloy wheels or the lighter 12-litre engine, but by no stretch of the imagination is this a gaffer's motor.

Of course plenty of Continental operators are already running premium tractors at that weight and above, so the AE's tare will not bother them.

The AE is not just high; it's long. The wheelbase options are 3.9 or 4.12m, so thank heavens for the 16.5m artic limit. With a recommended fifth-wheel position 47mm ahead of the back axle and a 254inm gap between the back of the cab and the front of the trailer, the AE should at least couple up to long pin position trailers of any dimension.

So who will buy the AE? The obvious answer is the growing band of longdistance owner-drivers and small fleet operators who want a flagship tractor that stands out from the crowd and provides an exceptional standard of driver comfort. Whether they go for the Renault or Mack engine will depend on how much they are prepared to pay for extra productivity.

After some 2,700km on the road in the AE500 we are left in no doubt that it is fast, comfortable and quiet. It has good brakes, excellent road-holding and the kind of working environment that most drivers only dream of. Its engine packs a punch that places it well on a par with the best of the Continentals. The AE500 has one final ace up its sleeve: its price. By any yardstick it is competitive, bearing in mind that luxurious level of equipment. For £65,750 you get one hell of a lot of truck for your money.

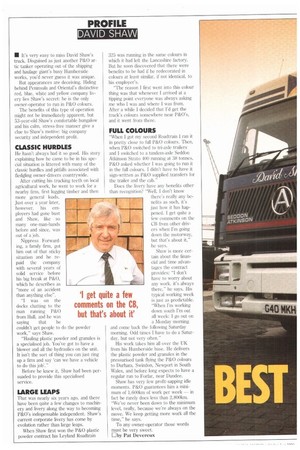

To sum up, our verdict on the AE500 is a qualified "impressed". We'll wait until we've tested a right-hooker before going overboard for the big newcomer, but if our results on the Continent are anything to go by, we hope Renault Truck Industries doesn't keep us waiting too long. • It's very easy to miss David Shaw's truck. Disguised as just another P&O artic tanker operating out of the shipping and haulage giant's busy Humberside works, you'd never guess it was unique.

But appearances are deceiving. Hiding behind Peninsula and Oriental's distinctive red, blue, white and yellow company livery lies Shaw's secret: he is the only owner-operator to run in P&O colours.

The benefits of this type of operation might not be immediately apparent, but 53-year-old Shaw's comfortable bungalow and his calm, stress-free manlier give a clue to Shaw's motive: big company security and independent profit.

CLASSIC HURDLES

He hasn't always had it so good. His story explaining how he came to be in his special situation is littered with many of the classic hurdles and pitfalls associated with fledgling owner-drivers countrywide.

After cutting his trucking teeth on local agricultural work, he went to work for a nearby firm, first lugging timber and then more general loads. Just over a year later, however, his employers had gone bust and Shaw, like so many one-man-bands before and since, was out of a job.

Nippress Forwarding, a family firm, got him out of that sticky situation and he repaid the company with several years of solid service before his big break at P&O, which he describes as "more of an accident than anything else".

"I was on the docks chatting to the man running P&O from Hull, and he was saying that he couldn't get people to do the powder work," says Shaw.

"Hauling plastic powder and granules is a specialised job. You've got to have a blower and all the hydraulics on the unit. It isn't the sort of thing you can just ring up a firm and say 'can we have a vehicle to do this job'."

Before he knew it, Shaw had been persuaded to provide this specialised service.

LARGE LEAPS

That was nearly six years ago, and there have been quite a few changes to machinery and livery along the way to becoming P&O's indispensable independent. Shaw's current corporate livery has come by evolution rather than large leaps.

When Shaw first won the P&O plastic powder contract his Leyland Roadtrain 325 was running in the same colours in which it had left the Lancashire factory. But he soon discovered that there were benefits to be had if he redecorated in colours at least similar, if not identical, to his employer's.

"The reason I first went into this colour thing was that whenever I arrived at a tipping point everyone was always asking me who I was and where I was from. After a while I decided that I'd get the truck's colours somewhere near NW's, and it went from there.

FULL COLOURS

"When 1 got my second Roadtrain I ran it in pretty close to full P&O colours. Then, when P&O switched to tri-axle trailers and I switched to a tandem-axle Seddon Atkinson Straw 400 running at 38 tonnes, P&O asked whether I was going to run it in the full colours. I didn't have to have it sign-written as MO supplied transfers for the trailer and the cab."

Does the livery have any benefits other than recognition? "Well, I don't know there's really any benefits as such, it's just how it has happened. 1 get quite a few comments on the CB from other drivers when I'm going down the motorway, but that's about it," he says.

Shaw is more certain about the financial and time advantages the contract provides: "I don't have to worry about any work. it's always there," he says. His typical working week is just as predictable. "When I'm working down south I'm out all week: I go out on a Monday morning and come back the following Saturday morning. Odd times F have to do a Saturday, but not very often."

His work takes him all over the UK from his Humberside base. He delivers the plastic powder and granules in the pressurised tank flying the P&O colours to Durham, Swindon, Newport in South Wales, and before long expects to have a regular run to Forfar, near Dundee.

Shaw has very few profit-sapping idle moments. P&O guarantees him a minimum of 1,600km of work per week — in fact he rarely does less than 2,800km. "We've never been down to the minimum level, really, because we're always on the move. We keep getting more work all the time," he says.

To any owner-operator those words must be very sweet. Oby Pat Devereux BRIDGE BLUES

• I Living had the unfortunate task of trying to drive North through the Dartford Tunnel last week — in between wondering how much money is collected in tolls in an hour and suspecting it's more than I earn in a month — I looked at the new bridge which is being constructed.

1 for one would like to know how high it will be at its central point and the odds on my curtainsider being blown off the side should there be a strong wind. That is assuming the poor old thing can climb the quite alarming gradient in the first place.

Also, I would hope that the cost of a single crossing will not reach that of the Humber bridge. Otherwise it will be cheaper to go around the other way, or better still through the middle of London like in the "good old days", which can still be quicker at certain times of the day in preference to joining several miles of traffic and paying for the privilege. AR Goss, Sandi:. Beds.

VIVA VOLVO • Having recently returned from a magical trip to America with my wife Sonia, I felt I must say thank you to Commercial Motor and a few personalities at Volvo Trucks GB regarding the parts competition which you ran in March. As the Hawk reported earlier this year, I was the lucky one chosen as the winner.

Volvo flew us out to Virginia to inspect the Volvo White GM truck plant at New River, corn-tesy of plant manager Dennis Sethi11. What a fantastic place. After a few day's bliss in Virginia we flew to Orlando for the remainder of the holiday in

Florida. Our memories will last forever and if I did the trip again I wouldn't change a thing.

I close by thanking you, Brian Weatherley and your staff at CM together with Alistair Robinson, Volvo parts manager: Richard Smith, promotions manager; and Terry Wilson, Volvo's advertising manager. They certainly put on a show for us.

Perhaps for me the best touch of all, the day after we got back. My wife had a phone call from Terry Wilson at Volvo to see if everything had been all right.

Volvo cares, and it shows. Thank you once again.

Bryce Rennison, Donald Ireland, Hexham, Northumberland.

COVERING UP • We read with interest Commercial Motor's reference to Pioneer Aggregates' claim to be the first company to insist its tipper drivers must cover their loads when transporting from quarries (CM 30 August4 September).

Back in March my client Titcon launched an "undercover operation" to save towns and villages in the North of England from the nuisance of stray chippings and dust from lorries.

The scheme, which was initiated by management, means that all haulage contractors transporting Tilcon materials must sheet their loads before leaving the quarries.

Since then special bays have been constructed to enable drivers to sheet up their loads in safety.

1 think this proves the Pioneer claim to be groundless. Duncan Greenwood, Director, The Public Relations Company, Harrogate, North Yorks. SOLDIERING ON • Further to the most interesting article by Pat Kennett about the AEC V8 Mandator (CM 20-26 September) I can confirm that at least four vee-eight-engined vehicles are still in service. Three are Mandator based-vehicles, although they are adapted to specialist uses. They are:

o LVL 164H — Specialist gas cylinder carrier operated by Lincoln Ferrous Metals, and formerly the Clayton Dewandre brake development trailer prime mover.

U RWO 533G — Recovery vehicle operated by RF Brookes of Leicester.

O CGX 259H — Recovery vehicle operated by Fleur de Lys Pies of Leamingon Spa.

All three are fitted with the six-speed overdrive gearbox.

The vee-eight-engined AEC Sabre coach (SAB 784) operated by Kemps of Thanet is still going strong after 20 years' service. It is believed to be the only survivor out of the four Sabres that were built (the other three have been exported to Australia, Israel and South America).

Strong rumours also abound of a six-wheeled AEC veeeight-powered cattle transporter which leaves modern vehicles gasping in its wake on the motorways, and at least five other vee-eight tractive units survive, either in the hands of preservationists or lying derelict at former operators' premises.

There is also a more positive link between the V8 Mandator and the TL12 Marathon than perhaps Pat Kennett realises. The vee-eight engine and the TL12 engine were designed by the same man, Keith Roberts, whose design brief for the veeeight was to design and de velop an engine that with later turbocharging and chargecooling would give AEC and Leyland a power unit capable of 400bhp in the 1970s and 1980s.

Alas, it was never to be. WG Edge,

AEC Society Secretary, Cambridge.

BEL THRIVES

• While appreciating you carrying our "speedy repair" news item (CM 20-26 September) I would like to point out that we are Bus Engineering Ltd and not Bus Engineering Group Ltd.

We are not connected with Bus Engineering Group Ltd, which went into administrative receivership in June this year. WS Laird,

Managing Director, Bus Engineering Ltd, Willesden, London.