Over 65 m.p.h. with Six-wheeler

Page 44

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

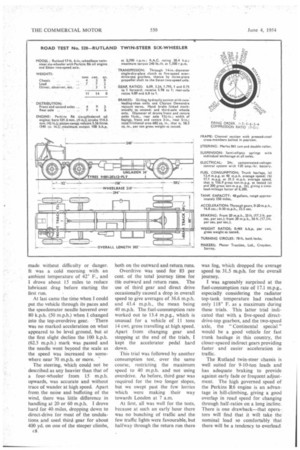

New Rutland Light Six-wheeler Built for High-speed Operation on the Continent: Transmission Includes an Overdrive-top Gearbox and a Two-speed Axle

by Laurence J. Cotton, M.I.R.T.E.

APART from the thundering of the wind as it rushed past my ears on the open chassis, all other noise was lost when 1 changed gear from direct to overdrive-top at 50 m.p.h. on the Rutland six-wheeler, and then accelerated to well over 65 m.p.h. The twin-steer Stuka, which is built specifically for fast schedules on the Continent, is an unusual chassis, especially in respect of its overall gearing which includes an Eaton two-speed rear axle.

The operator specified a solo machine with space in the cab for a relief crew and sleeping quarters, and a reasonable body length for light but bulky loads. It was required to operate a fast schedule across flat country, but as many forward gears as possible were needed to enable easy climbs on long gradients. Similarly, a large braking area was demanded to control the vehicle on the long declines. The price of the chassis and its economy iri fuel were also important factors.

To meet these needs, a special long,frame version of the Stuka fourwheeler has been built with the span

between the first and rear axles shortened by introducing a second steering axle, giving a wheelbase of 13 ft. 2 in. between the second and third sets of wheels. The 20-ft. frame length, from the back of the engine cover to the end of the chassis, gives room for a long body, in addition to the reserve quarters for the relief crew.

Advantages of introducing the second axle include doubling the front-axle brake frictional area and improved life to the springs, shackle pins and king pins, and in the general distribution of load. The tyres, 9.00-20 in. of 12-ply rating, would afford a total vehicle weight of 13 tons 16 cwt. on the overseas schedule, thus providing a safe margin for high-speed operation of the Rutland, which will be loaded to about 12 tons gross.

An oil engine that would give a flexible performance was included in the operator's requirements. This is fulfilled by the Perkins R.6 engine, which is governed to 2,700 r.p.m., at which speed it develops 108 b.h.p. have always admired the sturdy build and " oversize " components used in the Rutland vehicles, and the twinsteer version is no exception.

In evidence of this, it has a 14-in.diameter clutch and David Brown 557 five-speed overdrive-top gearbox. The three-piece propeller shaft, with Layrub 100 heavy-duty couplings, is equally well related to the torque.

The driving axle, an Eaton 16,500 two-speed unit, has electrically operated shift gear and ratios of 4.89 and 6.8 to 1, which, in conjunction with the gearbox overdrive, gives a top ratio of 3.66 to 1. This vehicle is built for a specified type of operation, but the Condor 8-ton fourwheeled 15-ft. 6-in.-wheelbase chassis with lower gear ratios and a second steering axle, is a standard Rutland model which would be more suitable for 9-ton loads in this country.

Other details of the Stuka twinsteer chassis include a Clayton Dewandre 687 servo with Girling hydraulic brake gear to two-leadingshoe units at all axles. The hand brake is linked to both the second and third axles. The 48-gal. fuel tank can be supplemented by a. 24-gal. tank to increase the operating range, and the controls of the test vehicle were arranged for left-hand drive.

In addition to fitting a Marles 861 heavy-duty steering box, the wear on the steering-ball ends lS reduced. by introducing the second axle and distributing the load over twin auxiliary drop arms in the linkage between the steering box and centre axle.

Seven huge concrete blocks were put on the chassis for testing, these. together with the saddles and ties,

totalling 7 tons 7i cwt. The test was started in normal working hours, but it was soon evident that high-speed consumption trials would have to be deferred until very early the following morning, before other traffic was on the roads. At first I accelerated through the range of gears, using the half-stops provided by the two-speed axle, but always there was some hindrance before engaging the overdrive.

After locating a level road suitable for measuring acceleration and braking performance, I started the is. Smooth starts were made rig low-second, and the best results re obtained by making a full mge to low-third and then very ckly to high-third to reach n.p.h. The times from 0-20 m.p.h. .e 16.8 sec., and from 0-30 m.p.h., I sec. There was no suitable und locally to extend these tests tigher speed.

tested the brakes after 100 miles' driving and found the efficiency retained and above 0.5g., despite el locking and time delay in the un. The wheels locked evenly ill axles when the brakes were 1 on the crown of a wide road, I found adequate retardation when braking from 50 and 60 m.p.h. in subsequent stages of testing. Brake shoes 3 in. wide on the first and second axles and 5 in. wide at the rear provide a large frictional area, which is needed when braking from high speed.

The Rutland was put on its mettle when I drove it up some of the hills in Surrey and Kent, the inclines being far more severe, if shorter, than the mountain roads of the Continent. First there was Spout Hill, which has a 1-in-6.5 section, where high-first gear was required, and, as a precautionary measure because of traffic, I used the lower ratio of the axle when starting. At first the action of the two-speed axle was sluggish, caused possibly by the drag of cold lubricant and the inherent stiff operation of a new unit. When tackling Saltbox Hill, leading up to Biggin Hill aerodrome, I engaged bottom gear at an early stage, and when reaching the I-in-6 section the engine speed fell slowly almost to stalling point.

I experienced a few anxious moments, when suddenly there was a boast of power as the gear train slipped from high to low ratio in the axle. Although the lower ratio had been selected when starting the climb, the change was delayed, presumably because of stiffness, but this misdemeanour was an isolated case.

With the axle in the low-ratio drive, there was abundant power to complete the climb, and I would not hesitate to take the Rutland up any -in-6 gradient. The water temperature rose but little during this climb, and generally the engine was overcooled for operation in this country without radiator blanking.

The consumption tests were started at 5 a.m., when the vehicle was headed towards the Rochester Way, which was the nearest approach I could find to simulate the Continental trunk roads. By comparison the Rochester Way is "mountainous," but with no other traffic at such an early hour the fast trial was soon made without difficulty or danger. It was a cold morning with an ambient temperature of 42° F., and I drove about 15 miles to reduce lubricant drag before starting the first run.

At last came the time when I could put the. vehicle through its paces and the speedometer needle hovered over 80 k.p.h. (50 m.p.h.) when I changed into the top-overdrive gear. •There was no marked acceleration on what appeared to be level ground, but at the first slight decline the 100 k.p.h. (62.5 m.p.h.) mark was passed and the needle went beyond the scale as the speed was increased to somewhere near 70 m.p.h. or more.

The steering, which could not be described as any heavier than that of a four-wheeler from 15 m.p.h. upwards, was accurate and without trace of wander at high speed. Apart from the noise and buffeting of the wind, there was little difference in handling at 20 or 60 m.p.h. I drove hard for 40 miles, dropping down to direct-drive for most of the undulations and used. third gear for about 400 yd. on one of the steeper climbs,

c8 both on the outward and return runs.

Overdrive was used for 83 per cent. of the total journey time for the outward and return runs. The use of third gear and direct drive occasionally caused a drop in overall speed to give averages of 36.6 m.p.h. and 43.4 m.p.h., the mean being 40 m.p.h. The fuel-consumption rate worked out to 13.4 m.p.g., which is unusual for a vehicle of 11 tons 14 cwt. gross travelling at high speed. Apart from changing gear and stopping at the end of the trials, I kept the accelerator pedal hard down.

This trial was followed by another consumption test, over the same course, restricting the maximum speed to 40 m.p.h. and not using overdrive. As before, third gear was required for the two longer slopes, but we swept past the few lorries which were making their way towards London at 7 a.m.

At first, all was well for the tests, because at such an early hour there was no bunching of traffic and the few traffic lights were favourable, but halfway through the return run there

was fog, which dropped the average speed to. 3L5 1TLph. for the overall journey.

I was agreeably surprised at the fuel-consumption rate of 17.1 m.p.g., especially considering the radiator top-tank temperature had reached only 118° F. as a maximum during these trials. This latter trial indicated that with a five-speed directdrive-top gearbox, and the two-speed axle, the "Continental special" would be a good vehicle for fast trunk haulage in this country, the closer-spaced indirect gears providing faster and easier acceleration in traffic.

The Rutland twin-steer chassis is well suited for 9-10-ton loads and has adequate braking to provide against early fade or frequent adjustment. The high governed speed of the Perkins R6 engine is an advantage in hill-climbing, giving a good overlap in road speed for changing through half-ratios on a long incline. There is one drawback—that operators will find that it will take the nominal load so comfortably that there will be a tendency to overload.