Retarders inereas

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

fety, save cash

ALTHOUGH retarders have been a popular fitment on Continental lorries and buses for many years, only during the last 10 years or so have they come to be accepted in the UK.

There are several possible reasons for this. In cv applica tion in Britain, the operator is penalised on payload, by the weight of the retarder. This is not the case in France, for example, where there is a dispensation against payload for retarder weight.

British operators are also notoriously loth to fit any device which costs them money but which is seemingly not an essential piece of equipment.

Coach and bus operators, by contrast, have been more wil ling to try them, and the couple of accidents involving runaway coaches have served to draw public attention to the existence of such devices.

In spite of this publicity, many people, even established operators, are unsure as to what is meant by a retarder.

Basically it's a device which is used to slow the vehicle without using its foundation brakes.

By definition, then, it is not a secondary brake, but rather an aid to reducing the speed of the vehicle on those occasions when full braking is not required. How, then, does the retarder differ from such things as e)(haust brakes and Jacobs brakes? Firstly, both these systems rely on the vehicle being in gear and the clutch engaged before they can have any effect on its speed. Thus if the driver misses a gear on a long downward slope and is stuck in neutral, the exhaust brake is useless. In addition, exhaust brakes are dependent both on engine capacity and road speed for their effectiveness.

The Jacobs brake (Jake brake) is far more effective than most ordinary exhaust brakes, as it turns the cylinder into a compressor by locking the valve. But it, too, will not work out of gear and can only be fitted to Cummins and Detroit Diesels.

By contrast, the retarder can be utilised on any type of vehicle, provided there is space to fit it in the chassis frame and, most importantly, it works whether the vehicle is in gear or not.

There are two main types of retarder available the electromagnetic and the hydraulic.

Telma, the French company, was a pioneer in the manufacture of the former type, which works by creating eddy currents within a metal disc rotating between two electromagnets. This sets up a force which opposes the rotation of the disc.

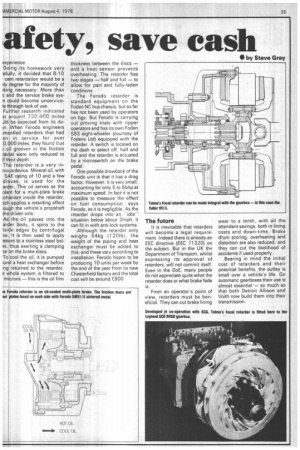

Originally the Telma was located in the propshaft, between the end of the gearbox and rear axle. This location is fine for coach chassis of conventional design, but the move by manufacturers to mid and rearengined set-ups meant that this was not always possible. To overcome the problem, Telma introduced its Focal-type retarder for fitment on either the gearbox rear face or on the nose of the differential.

In practice, it is always preferable to avoid differential location as this adds to unsprung weight — an undesirable feature. By working with gearbox makers such as Fuller and SCG, Telma has been able to offer a new gearbox tail casing with its larger retarders, thus reducing the space required and the weight of the unit.

This makes the unit a more acceptable proposition on heavier trucks, too, as the payload disadvantage has been reduced to about 135kg (3001b). The cost of the modification on a Fuller box is in the order of £300, while the retarder itself costs £1,000. Fitting labour is around £300.

There are four separate circuits in the Telma itself, although it's unlikely that t would all go at once, the c party issues instructions v each unit so that it can be connected.

Telma retarders are comr able with anti-skid systerm they can be modulated to fl with the cycling of the syster

Ferodo retarder

For the last ten years, Ferc the brake lining material mal has been working on hydraulic retarder design s able for both psv and truck stallation. It may seem stra that a maker of friction mat( should be working on a de+ which will dramatically red brake lining wear, but the c pany believes that retarders the coming thing.

In addition its design cludes friction material and z of similar technology to t employed on "wet" trac brakes, in which Ferodo has ex erience.

Do'ng its homework very 'ef Ily, it decided that 8-10 c t retardation would be a ly egree for the majority of iki g necessary. More than s a d the service brake sysn •euld become unservicele t rough lack of use.

Fu ther research indicated 3t round 250,000 miles _1 Id be expected from its dep. When Ferodo engineers ;al ntled retarders that had en in service for over 0,1100 miles, they found that o I grooves in the friction rte al were only reduced to If t eir depth.

Th retarder is a very innioLis device. Mineral oil, with SAE rating of 10 and a few dit'ves, is used for the ar er. This oil serves as the Dla t for a multi-plate brake )ch nism inside the retarder, tic applies a retarding effect .ou h the vehicle's propshaft th driven axle,

As the oil passes into the ar er body, it spins to the tside edges by centrifugal ce. It is then used to apply )ssure to a stainless steel belvs, thus exerting a clamping ce on the brake discs.

To cool the oil, it is pumped )und a heat exchanger before lig returned to the retarder. e whole system is filtered to microns — this is the oil film thickness between the discs — and a heat sensor prevents overheating_ The retarder has two stages — half and full — to allow for part and fully-laden conditions.

The Ferodo retarder is standard equipment on the Foden NC bus chassis, but so far has not been used by operators on hgv. But Ferodo is carrying out proving trials with tipper operators and has its own Foden S83 eight-wheeler (courtesy of Fodens Ltd) equipped with the retarder. A switch is located on the dash to select off, half and full and the retarder is actuated by a microswitch on the brake pedal.

One possible drawback of the Ferodo unit is that it has a drag factor. However, it is very small, accounting for only 5 to 6bhp at maximum speed. In fact it is not possible to measure the effect on fuel consumption. says Ferodo, as it is negligible. As the retarder drops into an "idle'' situation below about 2mph, it can fit in with anti-lock systems.

Although the retarder only weighs 54kg (120Ib), the weight of the piping and heat exchanger must be added to this, and these vary according to installation. Ferodo hopes to be producing 10 units per week by the end of the year from its new Chesterfield factory and the total cost will be around £900. The future

It is inevitable that retarders will become a legal requirement. Indeed there is already an EEC directive (EEC 71320) on the subject. But in the UK the Department of Transport, whilst expressing its approval of retarders, will not commit itself. Even in the DoE, many people do not appreciate quite what the retarder does or what brake fade is.

From an operator's point of view, retarders must be beneficial. They can cut brake lining wear to a tenth, with all the attendant savings, both in lining costs and down-time. Brake drum scoring, overheating and distortion are also reduced, and they can cut the likelihood of accidents if used properly.

Bearing in mind the initial cost of retarders and their potential benefits, the outlay is small over a vehicle's life. On automatic gearboxes their use is almost essential — so much so that both Detroit Allison and Voith now build them into their transmission.