Security shroud!

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

IN AUSTRIA Semperit is the largest company in the rubber business. Although it produces a wide range of goods from rubber gloves to inflatable sailboats, tyres constitute over 60 per cent of total production. Almost 50 per cent of that figure, about 76,000 tons of tyres, are exported each year.

Semperit (UK) Ltd, with its head office at Slough, in Berkshire, made its first inroads into the British market, primarily with car tyres, in the late Sixties when the then new tyre regulations imposed greater strain on indigenous supplies. Such was the success that a new factory was built in Dublin to meet the demand.

However, the commercial vehicle tyre has been slower to catch on, and although Semperit makes both cross-ply and radial tyres. it is with its range of all-steel radial tyres that the company believes its future prosperity lies.

In a market where the company has only just over one per cent penetration, it must be unusual to find a fleet operator who fits its brand almost exclusively.

To find out why, I went along to see Graham Smith, group transport manager for Booker Belmont Wholesale Ltd, at the Kinlock depot in Burgh Heath, Surrey.

Graham has responsibility for just over 300 road-going vehicles, mainly Bedfords ranging from CF vans to 32-ton TM tractive units, in addition to yard shunters and other pieces of loading equipment operating out of 15 depots.

The practicalities of running such a large fleet necessitates a certain amount of rationalisation, for there would just not be enough hours in the day to deal with suppliers of a lot of dif ferent makes of vehicle, he told me.

This carries with it 'certain financial benefits, for with such a large fleet the best discount rates are nearly always available. Graham extends this theme of operation to include tyres so that one make, Semperit, is fitted to 95 per cent of the fleet, which still leaves room to keep an eye on alternative products.

What I really wanted to know was why he chose Semperit in preference to other makes. It seems that at the time the decision was made to consolidate on one make, his suppliers were the Standard Tyre Co of Uxbridge. Semperit distributors for the South of England at that time. Standard has about 40 outlets and is incidentally one of the first distributors to offer the same sort of discount to the general public as was available to the trade.

Standard offered a service with Semperit which they could not guarantee to maintain with any other make of tyre. One drawback to this choice was that the Semperit tyre was not fitted_ as original equipment, but to overcome this Standard agreed to do an exchange service on the day that each new vehicle was delivered so that conformity where possible existed through out the fleet. • Later, Swanwick Tyres, founded by ex-members of the Standard organisation after the latter withdrew from the commercial tyre market, were able to continue the scheme.

' One of the benefits put forward by Semperit for using its tyre is that it can be regrooved, rebuilt and finally regrooved again, offering the equivalent of almost four tyre lives for little more than one and a half times the cost of a new tyre.

However, this is not an influential factor contributing to Graham's choice. For, wherever possible, it is his conviction, backed up by 26 years in the business of running a commercial fleet, that with the discount he is able to command as a large fleet operator, in conjunction with the return price on each used carcass, the difference in cost is a small price to pay for the safety and reliability a new tyre has to offer.

He admits that perhaps he is fortunate that the initial cost has been built in over a number of years, but readily concedes that should the tyre costs ever increase, as a greater percentage of his overall transport costs, he would have to think again and find ways to reduce them.

If this meant fitting remoulded tyres then the Semperit system, allowing the use of his own carcasses, would seem the best alternative, but in own opinion would be a ri grade step.

Unless people were prep; to use rebuilt tyres, Grah2 own philosophy would soon into financial difficulties, ar is to his advantage that ot are not financially able to sl his high standard but inst rely on the undoubted impr ments in the technology gai over recent years by respon: tyre retreaders.

Semperit's own condit. for accepting a carcass are to be more stringent than of most other retread systE and stipulate the use of its carcasses, which may noi recycled more than once.

Damage to steel plies cal reason for refusai, but no least the outer steel bracing be replaced, using wire frorr same source as is used by world's leading common steel radial tyre manufacture Under a smokescreer secrecy I was allowed to visii Nova Tyre Co at Alton in Ha shire, the only people out Austria to'have authority to c out the Semperit rebuild cess When Semperit's mane merit sounded the company for technical competence, were surprised that they could pick up a point or 1 Director Don Meeks, whc engineer with the Blue P factory, at one time the big. retreader in Britain, and J Phillips, whose experience included involvement in the up of Michelin's plants in trail , Canada and the USA rnior recently a driving force the development of the ipre t tyre, were already ned to the difficulties of 1-to-bead rebuilds involving replacement of bracer plies. )nc at the factory. John

m through the Semperit jild rocess. I emphasise the Iperit process, for as yet this .eserits only a small part of factory's total throughput. 3rrivOl the tyre is placed on a )adeland checked visually obvious faults, then onto a tector machine which is able letect less obvious faults in wire plies of the carcass. )nce a tyre is accepted, a job .et accompanies the tyre nigh each stage of the uild and ensures that the omekreceives his own cars bOck. As a secondary ck, the tyre is given a serial aber which is chalked on the de wall.

1t the next stage, the tyre ,es onto a buffing machine emove the surface rubber.

tyre is inflated to 18 psi, ch gives it sufficient rigidity btainithe correct profile. Any )ir thnIt is required, including ace rent of the top bracing is done at the next stage by lachine supplied by the lperit factory. The process is ;Lie to Semperit and only one atyre manufacturer.

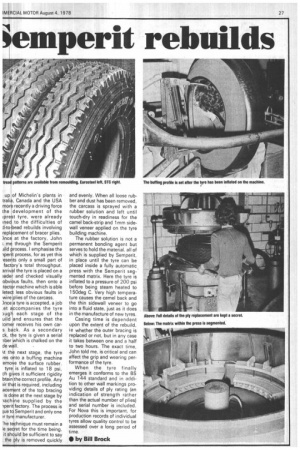

he technique must remain a e secret for the time being. it should be sufficient to say the ly is removed quickly and evenly. When all loose rubber and dust has been removed, the carcass is sprayed with a rubber solution and left until touch-dry in readiness for the camel back-strip and 1mm sidewall veneer applied on the tyre building machine.

The rubber solution is not a permanent bonding agent but serves to hold the material, all of which is supplied by Semperit, in place until the tyre can be placed inside a fully automatic press with the Semperit segmented matrix. Here the tyre is inflated to a pressure of 200 psi before being steam heated to 150deg C. Very high ternperature causes the camel back and the thin sidewall veneer to go into a fluid state, just as it does in the manufacture of new tyres.

Casing time is dependent upon the extent of the rebuild, ie whether the outer bracing is replaced or not, but in any case it takes between one and a half to two hours. The exact time, John told me, is critical and can affect the grip and wearing performance of the tyre.

When the tyre finally emerges it conforms to the BS Au 144 standard and in addition to other wall markings providing details of ply rating (an indication of strength rather than the actual number of plies) and serial number is included. For Nova this is important, for production records of individual tyres allow quality control to be assessed over a long period of time.