How to tilt a fixed cab

Page 72

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

EYLAND'S design for its nowosolete Ergomatic cab, used on uffalo, Bison, Octopus and /nx models, went only halfway providing an acceptable /stem of fitting.

Chassis bolts are used to lo3te and secure the cab to the iassis, but a pump and hyraulic ram are provided to lift it om the rear, tilting it about ont-mounted pivot points. The roblem of releasing the two 3ar mounting bolts, however, is !ft to the workshop mechanic. Regular greasing and a suitble piece of timber to compress le springs can help, but at best is an awkward and time conuming business and might ave remained so if Bill Perry of 'armee had not chanced to put le problem to Eric Ball of Ball :omponents Ltd, Leek, The Quick Tilt device that nally resulted from this meet

ig the operation to be ompleted in less than two mites instead of the normal 25 to minutes, though I have nown of some stubborn bolts hat still had to be burnt off.

The new cab lock consists of in over centre cam clamp arangement, but before it can be itted, modification to existing .eyland components is necesiary, I visited Redland Roadstones mgineer Reg Greatbatch at Enlerby, near Leicester, and he old me he had the device fifted .o 37 of his vehicles. "Some of our vehicles start work at four in the morning to get Tarmac and aggregate to the customer at the beginning of his day. The Quick Tilt device can mean the difference between getting a fault put right in time for the next day's work or losing the vehicle for a day."

Other customers who have tried the device and made repeat orders include. the NCB, the Distillers Company, Gilbraith, British Steel, Fine Fair, Tunnel Cement, Tarmac and the Thames Water Board.

Ball Components say a pair of units can be fitted in about three and a half hours. The first job is to remove the seating cup and any other auxiliary equipment from the turret top which can then be marked up before the top 4.5 inches is cut off. It is suggested this is done using a flame cutter with the turret still attached to the vehicle, and a protective asbestos shield is supplied for the purpose.

Once the burrs have been ground off, the next step is to cut away a small portion of the wheel arch and then assemble the new cab top mounting bracket using salvaged parts from the original and refit.

To fit the base assembly, the turret must first bP drilled, but all that then remains Is to adjust for fore and transverse position and tension the clamp to between 70 and 80 lb/ft.

Many of the original components are used, but on older vehicles Reg Greatbatch has found it pays to replace top and bottom mounting rubbers and, for a quick vehicle turnround, a spare pair of turret brackets allows the only major component modification to be completed independent of the vehicle.

Once fitted, no special tools are required, other than the pump handle. The driver himself is able to raise the cab to carry out routine checks.

With the Ergomatic cab being phased out, it is unlikely that Leyland will show much interest in the tilt device, though I believe something similar was devised for the AMOCO fleet about four years ago.

Ball Components have submitted their device to extensive trials over a 12-month period on vehicles operating over rough terrain as well as with roadgoing vehicles in major fleets.

The units sell at £150 per vehicle, and can be fitted for around £60, with discount on larger orders. As with the Bennett kit, tt device from Ball could pay i itself the first time it is used. will certainly save time — tempers.

Twenty years after Vauxh Motors first produced i popular medium-weight ran of commercial vehicles, an int pendent Buckinghamshire fi has come up with a relativ inexpensive way to make fixed cab tilt.

Reg Bennett, a director Ben netts of Holyport Ltd, got idea after seeing Bedford's n TL range, introduced last year "The floor pans of the t cabs are almost identical," told me, "but the cost oi conversion using Bedford pE worked out too expensive. 1 TL uses a different steering

for a start. But not to be put off we decided to see what we could produce."

The kits contain all the bracketry, pivots, pipes, pipes and cables down to the smallest nut and bolt needed to complete the work. The whole assembly is bolted together and makes use of existing holes drilled in the chassis where possible.

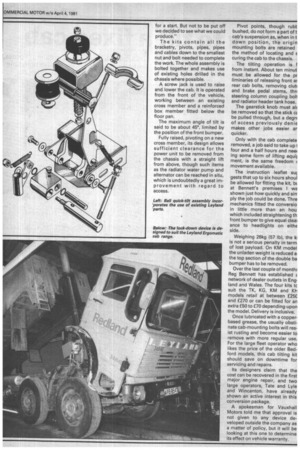

A screw jack is used to raise and lower the cab. It is operated from the front of the vehicle, working between an existing cross member and a reinforced box member fitted below the floor pan.

The maximum angle of tilt is said to be about 45°, limited by the position of the front bumper.

Fully raised, pivoting on a new cross member, its design allows sufficient clearance for the power unit to be removed from the chassis with a straight lift from above, though such items as the radiator water pump and alternator can be reached in situ, which is undoubtedly a great improvement with regard to access.

Pivot points, though rubt bushed, do not form a part of t cab's suspension as, when in t down position, the origin mounting bolts are retained the method of locating and F. curing the cab to the chassis.

The tilting operation is f from instant. About ten minut must be allowed for the pr liminaries of releasing front ar rear cab bolts, removing clut■ and brake pedal stems, thri steering column coupling boll and radiator header tank hose.

The gearstick knob must al: be removed so that the stick CE be pulled through, but a degr( of access previously denie makes other jobs easier ar quicker.

Only with the cab complete removed, a job said to take up four and a half hours and nee( ing some form of lifting equir ment, is the same freedom r movement available.

The instruction leaflet suc gests that up to six hours shoul be allowed for fitting the kit, Ix at Bennett's premises 1 wa shown just how quickly and sirr ply the job could be done. Thre mechanics fitted the conversio in little more than an hou which included straightening th front bumper to give equal deal ance to headlights on eithe side.

Weighing 26kg (57 lb), the ki is not a serious penalty in term of lost payload. On KM model the unladen weight is reduced a: the top section of the double ba bumper has to be removed.

Over the last couple of month.f. Reg Bennett has established z network of dealer outlets in Eng• land and Wales. The four kits tc suit the TK, KG, KM and KH models retail at between £25C and £270 or can be fitted for an extra £50 to £70 depending upon the model. Delivery is inclusive. Once lubricated with a copperbased grease, the usually obstinate cab-mounting bolts will resist rusting and become easier to remove with more regular use. For the large fleet operator who likes the price of the older Bedford models, this cab tilting kit should save on downtime for servicing and repairs.

Its designers claim that the cost can be recovered in the first major engine repair, and two large operators, Tate and Lyle and VVincanton, have already shown an active interest in this conversion package.

A spokesman for Vauxhall Motors told me that approval is not given to any device developed outside the company as a matter of policy, but it will be looking at this one to determine its effect on vehicle warranty.