Pictures by Harry Roberts THE FUTURE of dozens of tipper

Page 74

Page 75

Page 76

If you've noticed an error in this article please click here to report it so we can fix it.

companies throughout the country engaged in the removal of waste material from National Coal Board tips is in the balance. Whether or not it will be a viable proposition for them to continue transporting millions of tons annually of this colliery spoil depends largely on the outcome of a court hearing which will probably take place later this year. Shale removal contractors' associations are, however, ready and eager to challenge the proposal made by the Inland Revenue that a mineral rating should be imposed on material from these tips.

If in the end the contractors lose and are forced to pay rates together with retrospective payments back to 1961, when these operations got going in a big way, it will certainly have a most serious effect on the whole business which of late has grown to major proportions. The probable result in most parts of the country would be to stop the removal of colliery tip waste except by major contractors where a shale heap or tip is almost adjacent to the civil engineering scheme involved.

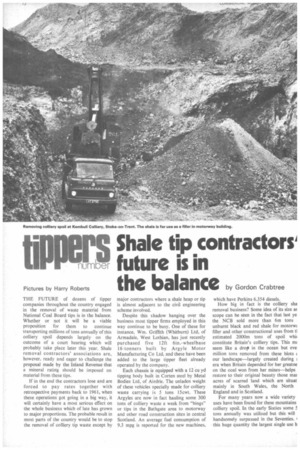

Despite this shadow hanging over the business most tipper firms employed in this way continue to be busy. One of these for instance, Wm. Griffith (Whitburn) Ltd, of Armadale, West Lothian, has just recently purchased five 12ft 6in.-wheelbase 16-tonners built by Argyle Motor Manufacturing Co Ltd, and these have been added to the large tipper fleet already operated by the company.

Each chassis is equipped with a 12 Cu yd tipping body built in Corten steel by Metal Bodies Ltd, of Airdrie. The unladen weight of these vehicles specially made for colliery waste carrying is 5 tons 15ewt. These Argyles are now in fact hauling some 300 tons of colliery waste a week from "bings" or tips in the Bathgate area to motorway and other road construction sites in central Scotland. An average fuel consumption of 9.3 mpg is reported for the new machines, which have Perkins 6354 diesels.

How big in fact is the colliery sha removal business? Some idea of its size at scope can be seen in the fact that last ye. the NCB sold more than 6m tons unburnt black and red shale for motorwt filler and other constructional uses from ti estimated 2000m tons of spoil whis constitute Britain's colliery tips. This mt seem like a drop in the ocean but eve million tons removed from these blots ( our landscape—largely created during era when Britain depended for her greatne on the coal won from her mines—helps restore to their original beauty those mat acres of scarred land which are situat mainly in South Wales, the North England and in Scotland.

For many years now a wide variety uses have been found for these mountains colliery spoil. In the early Sixties some 5 tons annually was utilized but this will handsomely surpassed in the Seventies.

• this huge quantity the largest single use h en as a common filler in the construction road and railway embankments and the ing in of sites for building and other land 7.1amation purposes. There are two types colliery shale, black shale or minestone ing most often used as bulk fill and red ale coming from older tips where mbustion has occurred due to the lesser derstanding of earlier times and which 'ers more versatility in use. Minestone is raw shale as raised from the mine. odern techniques of coal separation and construction are such that combustion es not take place. Both types of material available in vast quantities, which are sily won without expensive quarrying ■ erations, for example blasting and ashing. Transport costs are about the ;hest factor in the whole operation of moval. However, the established network shale contractors ensures that delivery of material at a site is efficiently carried out tether the order is for a few tons of graded ale for a private drive or for a million tons a motorway project.

The Road Research Laboratory has ntributed to the examination of colliery ales and both minestone and red shale ye DoE approval. Minestone is generally preciated by road-building contractors, to find it economic in use, both in terms delivered costs and of final cost resulting

■ rn its convenience and speed in use. Red ).le is welcomed as an upper layer, since it )1/ides a clean dry running surface in all athers.

The nation's slag heaps now offer vast resources of low-cost filler material. The bid to clear these unsightly tips and also put to good use the material from them has in fact been given additional impetus by the announcement that Britain is to construct its second 1000 miles of motorway. The high level of road construction will therefore continue for many years to come and with it the opportunity to use more colliery spoils. Only a mineral-saving tax on the operation could interfere.

Road-works which have been started or projected in which minestone or red shale is used as a filler include the Liverpool outer ring road with 11m tons, part of M61 with 400,000 tons, parts of M62 with close on 2m tons, the Eccles by-pass with 500,000, the Midland link road which will most likely take another lm, 75,000 tons for approach roads for an overpass over the Bristol Parkway, and 4.5m tons for the Goole section of M62.

Something in the region of 14m tons of colliery waste has been used on British roads and land reclamation projects in the past two years. The NCB some time ago set up a Minestone Executive to promote the use of this type of shale. With headquarters in London it consists. of eight regionally based sales consultants and three technical advisers.

Saving transport costs

The executive continues to search for new and more sophisticated applications for minestone and in fact the Board's research and development department has success fully produced an artificial lightweight aggregate by applying high temperatures to the shale. The resulting material has proved ideal in concrete structures. However, this cannot be produced at the present stage of development at competitive prices.

Nowadays, although profits are being made by hauliers clearing shale from the tips, the way is by no means paved with gold. Transport costs are such that contractors for motorways naturally try to obtain fill from the nearest possible source to the point where it is to be used. In fact another advantage accrues if a source is found where the shale does not have to be hauled on a public highway allowing the contractor to avoid vehicle tax, insurance and the use of duty-free fuel.

If the tip is near enough to the site the contractor can dispense with conventional tippers or dump trucks and use instead' large-capacity motorized scrapers. When possible, therefore, a motorway contractor opens up a pit near to his project even if a colliery waste heap containing suitable fill is less than a mile from the site These pits are known as "borrowpits" in the construction industry and today can be seen derelict and abandoned throughout Britain's motorway corridors. Nowadays a contractor quite rightly has to obtain planning permission before he is allowed to open one of the borrowpits.

Despite the efforts of the Inland Revenue and the Lands Tribunal to impose a mineral rating backdated to 1961 on shale collected from Britain's colliery tips it is not beyond the bounds of possibility that in the near future an enlightened Department of the Environment may seek legislation to provide a subsidy to enable more waste to be taken from colliery tips so that it can be economically transported greater distances to motorways,. land reclamation sites and other projects aimed at improving the environment in which we live. This perhaps would have the effect of for some time putting off the inevitable day when the remaining slag heaps in Gt. Britain will have of necessity to be removed entirely at public expense.

Perhaps one of the most interesting factors is that the NCB, who is vitally interested in the sale of shale from colliery tips, does not regard its sale as a non-profit-making venture—nor is it likely in the foreseeable future to be regarded as a fringe NCB activity to be disposed of by Government.

Most of the work of transporting shale from the tips is contracted out by the Board through a main agent or by NCB's own people locally. When the Board is unable to tip dirt straight into a tip alongside a colliery and has to stow it away from the area a local haulier is most often used. On rare occasions old quarry workings have been used as storage areas although there has never been any concerted large-scale plan to move colliery waste from tips or direct from the mines to fill quarry holes from an environmental angle although this may happen in the 1950s.

Export prospects In the not too distant future the spoil from Britain's colliery tips may well have a saleable value on the Continent—particularly if Britain joins the Common Market. In Holland, for instance, many millions of tons have been put to use in the construction of dykes and other land reclamation schemes, the Government paying a special subsidy to tipper contractors to enable them to make such a project a viable one. In fact most of the shale used in sea defences has been imported by road and canal from the cc mining area of the Ruhr. This year the NC has been rewarded by orders from t Dutch Government for supplies of Briti colliery shale and it is not inconceivable th there is a promising field for tipp operators in exporting to that country.

Until recently unburnt colliery shale h only been used at a depth of at least 18i below any road surface in Britain becau of its tendency to be susceptible to frc damage. However. a Surrey Universi research programme sponsored recently 1 NCB demonstrated that the addition of small percentage of cement is sufficient make the material stable in the upper laye of .a roadway. This is, in effect, proving be a valuable new construction medium parts of the country where alternatives a scarce or require to be transport considerable distances.

Shale tipper contractors have been fore to overcome monumental difficulties in thr struggle to rid the landscape of the unwanted eyesores. They have been fao by completely unrealistic demands for rat levied by local authorities who have oft demanded as much as Sp for every ton material removed from a colliery hea Contractors who at first refuse to acce that they could be taxed on removing wh amounted to dereliction now fa retrospective claims which total mar hundreds of thousands of pounds.

In fact the Minestone Executive of tl NCB has liaised closely with members both Houses of Parliament to obta Government recognition of this grotestp situation. Although some relief has be promised, none has yet been forthcoming.