by Paul Brockington, MIMechE

Page 68

Page 69

Page 70

Page 72

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

A TIPPER is a tipper is a tipper. It may be regarded as the most basic of all load-carrying vehicles in terms of the work it has to do and in many cases the variety of loads it has to carry. It may be still the most abused type of vehicle on the road but since the regulations have been more strictly enforced and since the advent of hgv licensing of drivers, its role has assumed a certain dignity of purpose that has given it a new status.

Typically, it has to carry low-grade materials and this increases the importance of selecting the right type of vehicle for the job as a means of reducing wasteful running to a minimum. And more often than not the major consideration is the use of a type of body and tipping gear that matches the vehicle on which it is mounted as well as the

load it carries and the conditions of service, with due regard to the experience, capabilities and character of the drivers.

While the majority of run-of-the-mill tippers are nominally non-specialized vehicles, virtually every tipper operator's job is specialized to some extent. And although practically all bodybuilders produce a standard body or range of bodies to their own design or based on a kit of sections, they rarely build two or more 'bodies for different operators that are exactly alike apart from standard ranges for short-wheelbase tippers. And even the operators of short-wheelbase vehicles often "want something different" when it comes to detail.

How often does the bodybuilder know best what is suitable for his customer, the operator? In many cases he provides ; useful and reliable consultancy service notably with regard to payload potentia and the stability of long tippers. Som. operators know what they want and hay. the money to pay for it. A substantia minority would do well to rethink thei operations and Make a fresh start if the: could raise the cash. Operating a tipper on shoestring is no longer viable.

On these pages we take a look at som tippers which are either purpose-built to th operator's special requirements or whic have some particular feature or fitment c note, often at the specific request of th operator. Others in this section, while not ner or special in themselves, are interesting ft the way in which they have been applied t particular jobs, and the reasons why the have been chosen.

1.

The aluminium drop-sided tipper body in th photograph weighs 8cwt and was specie developed for mounting on a Ford D900 (no' the D1411) to enable the vehicle to carry payload of 10 tons. Produced by Derbyshit Tippers Ltd, of Staveley, nr Chesterfield, i close collaboration with Paynes (Heav Ci3mmercials) Ltd, Watling Street, Hinckle, Leics, the body has a capacity of 6 cu yd an is tipped by an Edbro 3LNC single-ram gea While the payload is currently 9 tons 14cwt, will later be increased to 10 tons by fitting th vehicle with tubeless tyres. A variety c extrusions is used supplied by differer companies, the light weight of the body bein in the main attributable to the construction the welded base frame in which the close spaced cross-bearers are interlaced wil runners of the same Section.

2 and 3.

Produced by Anthony Carrimore Sales Ltt Stanley, County Durham, the monocoqu aluminium body of this Foden-based tipper (" in carry 17 Cu yd of material. Operated by le Amalgamated Roadstone Corporation, it equipped with a spring-loaded tailboard ,echanism to prevent damage to the iilboard when the load is being tipped into a tap of material, while3in. timber side:tensions (3) are fitted to protect the des when the vehicle is being bucket loaded. le chassis is a Foden 8 XB28 eight-wheeler irrently plated at 24 tons gross and rated by le makers at 28 tons gross, the unladen eight of the vehicle being 9 tons 3 cwt. eying a length of 21ft, the body is tipped by 1 Anthony Carrimore S2OFC single-ram ur-stage gear. The floor is of aluminium ieet and kin. material is used for the front, des and tailboard.

and 5.

14-ton payload of slurry is carried in this )00gal tanker/tipper (4) that is mounted on 1 Albion Reiver 20-ton-gross chassis. It is )erated by Harry A. Skelton Ltd, Mill Lane, llongley, Warwickshire, is equipped with a iecial Skelton /VVelford covered tipping body 'oduced by Welford Engineering (Oldbury) d and is tipped by an Edbro 4LN single-ram iar, slurry being pumped into the vehicle )m a settling tank. The sloping tailboard (5) operated by a pneumatic system designed

Harry Skelton which provides quick iloading as well as cleanliness and will be ted to all Skelton tippers in due course. Arry Skelton points out that slurry is irmally carried in conventional tankers that ive a payload of about 8 tons when ounted on a 20-ton vehicle. It will be noted at the rear light and number plate are indantly mounted on a section of rubber fting which is said to reduce the frequency damage by 90 per cent.

3en tipping bricks at the end of a run, this 3dford TK /Reynolds Boughton converted x-wheeler is operated by J. and A. Jackson d, brick manufacturer of Manchester, and is rted with an Edbro drop-sided wood body hich has a length of 15ft to cater for the irriage of bricks on pallets as well as loose icks. A length of body that is exactly atched to the overall length of the pallets abilizes the load and obviates damage to e bricks. The wood floor, side boards and ilboard are steel lined. Rated at 17 tons oss, the vehicle can carry a payload of 91 ns, but normally operates wan a reduced ad. In the case of 16-ton-gross tippers in e fleet, composite aluminium /wood /steel idles are employed to provide a reduction in eight and enable a higher payload to carried. 7.

Operated by the Judkins Granite Co of Nuneaton, the Foden 24-ton eight-wheeler in this picture is six years old and was recently equipped with an Alusuisse M Series welded aluminium tipper body from a kit supplied by the Star Aluminium Co by a three-man bodybuilder, F. A. Gosling Ltd, of Nuneaton. The Edbro outrigged underbody rams and the hinge pins of the original assembly are retained in use, the thrust of the rams being transmitted to the central runners of the body substructure. The 18ft 6in. body has a length of 7ft 9in. and a height of 3ft. It was built in less than 14 days by two men with the occasional help of a third man. Band 9.

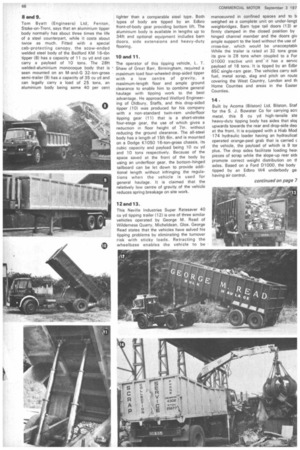

Tom Byatt lEngineers) Ltd, Fenton, Stoke-on-Trent, says that an aluminium tipper body normally has about three times the life of a steel counterpart, while it costs about twice as much. Fitted with a special cab-protecting canopy, the scow-ended welded steel body of the Bedford KM 16-tOn tipper (8) has a capacity of 11 cu yd and can carry a payload of 10 tons. The 28ft welded-aluminium monocoque body that is seen mounted on an M-and-G 32-ton-gross semi-trailer (9) has a capacity of 35 Cu yd and can legally carry a load of 25 tons, an aluminium body being some 40 per cent I lighter than a comparable steel type. Both I types of body are tipped by an Edbro front-of-body gear providing bottom lift. The aluminium body is available in lengths up to 34ft and optional equipment includes barn doors, side extensions and heavy-duty flooring.

10 and 11.

The operator of this tipping vehicle, L. T. Shaw of Great Barr, Birmingham, required a maximum load four-wheeled drop-sided tipper with a low centre of gravity, a maximum-length floor and ample ground clearance to enable him to combine general haulage with tipping work to the best advantage. He approached Welford Engineering of Oldbury, Staffs, and this drop-sided tipper (10) was produced for his company with a non-standard twin-ram underfloor tipping gear (11) that is a short-stroke four-stage gear, the use of which gives a reduction in floor height of 7in. without reducing the ground clearance. The all-steel body has a length of 15ft 6in. and is mounted on a Dodge K1050 16-ton-gross chassis, its cubic capacity and payload being 10 cu yd and 10 tons respectively. Because of the space saved at the front of the body by using an underfloor gear, the bottom-hinged tailboard can be let down to provide additional length without infringing the regulations when the vehicle is used for general haulage. It is claimed that the relatively low centre of gravity of the vehicle reduces spring breakage on site work.

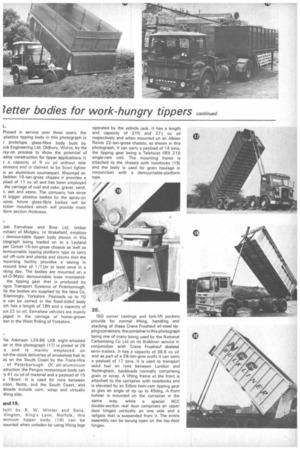

12 and 13.

This Neville Industries Super Ratesaver 40 cu yd tipping trailer (12) is one of three similar vehicles operated by George M. Read of Wilderness Quarry, Micheldean, Glos. George Read states that the vehicles have solved his tipping problems by eliminating the turnover risk with sticky loads. Retracting the wheelbase enables the vehicle to be • manoeuvred in confined spaces and to b weighed as a complete unit on under-lengt weighbridges. Barn type tail doors (13) ar firmly clamped in the closed position by hinged channel member and the doors giv ample support to the load without the use of cross-bar, which would be unacceptablf While the trailer is rated at 32 tons gros! its gvw is 28 tons when coupled to a For 01000 tractive unit and' it has a servic payload of 18 tons. It is tipped by an EMI' 6SC single-ram gear. The vehicles carry soli fuel, metal scrap, slag and pitch on route covering the West Country, London and th Home Counties a nd areas in the Easter Counties.

14.

Built by Acoma (Bilston) Ltd. Bilston. Staf for the S. J. Bowater Co for carrying scN metal, this 8 cu yd high-tensile ste heavy-duty tipping body has sides that slcq upwards towards the rear and drop-side doo at the front. It is equipped with a Hiab Mod 174 hydraulic loader having an hydraulical operated orange-peel grab that is carried c the vehicle, the payload of which is 9 tor plus. The drop sides facilitate loading heal pieces of scrap while the slope-up rear ski( promote correct weight distribution on th axles. Based on a Ford D1000. the body tipped by an Edbro W4 underbody ge. having air control.

The Alusuisse M4 series are all-welded aluminium tipper-bodies that have been specially designed for extra toughness to outlast most of today's bodies. How ? By the use of extrusions designed for the body, and alloys matched to operational requirements—alloys which are corrosion resistant and therefore need no painting. The result is a complete body made up as an integrated structure without local weaknesses, to handle rough, tough jobs in arduous conditions, year after year, and giving maximum payloads. Combine with this the lightweight properties of aluminium, and you have maximum durability for minimum weight penalty.

Proved in service over three years, the -plastics tipping body in this photograph is 3 prototype glass-fibre body built by uck Engineering Ltd, Oldbury, Worcs, by the ray-on process to show the potential of istics construction for tipper applications. It. 3 a capacity of 9 cu yd without side .ensions and is claimed to be 5cwt lighter in an aluminium counterpart. Mounted on Seddon 16-ton-gross chassis it provides a yload of 11 cu yd and has been employed the carriage of coal and coke, gravel, sand, t, ash and stone. The company has since It bigger plastics bodies by the spray-on icess; future glass-fibre bodies will be 3ction moulded which will provide more form section thickness.

Job Earnshaw and Bros Ltd, timber irchant of Midgley, nr Wakefield, employs 3 demountable tipper body shown in this otograph being loaded on to a Leyland per Comet 16-ton-gross chassis as well as lemountable tipping platform type to carry iod off-cuts and planks and claims that the mounting facility provides a saving in nround time of 1 /1Thr at least once in a irking day. The bodies are mounted on a 3d-O-Matic demountable base incorporat the tipping gear that is produced by igco Transport Systems of Peterborough, ile the bodies are supplied by the Isles Co, Stanningly, Yorkshire. Payloads up to 10 is can be carried in the fixed-sided body ich has a length of 18ft and a capacity of 3ut 22 cu yd. Earnshaw vehicles are mainly gaged in the carriage of home-grown iber in the West Riding of Yorkshire.

hie Atkinson L26.86 LXB eight-wheeled 3er in this photograph (17) is plated at 26 is and is maihly employed on nd-the-clock deliveries of smokeless fuel to as on the South Coast by the Trans-Hire , of Peterborough. Of all-aluminium istruction the Pengco monocoque body can ry 41 cu yd of material and a payload of 15 s 19cwt. It is used for runs between 3rton, Notts, and the South Coast, and :kloads include corn, scrap and virtually 'thing else.

and 19.

3uilt by B. W. Winter and Sons, tlington, King's Lynn, Norfolk, this minium tipper body (18) can be nounted when unladen by using lifting legs operated by the vehicle jack. It has a length and capacity of 21ft and 27-; cu yd respectively and when mounted on an Albion Reiver 22-ton-gross chassis, as shown in this photograph, it can carry a payload of 14 tons, the tipping gear being a Telehoist FF15 210 single-ram unit. The mounting frame is attached to the chassis with twistlocks (19) and the body is used for grain haulage in conjunction with a demountable-platform type.

20.

ISO corner castings and fork-lift pockets provide for normal lifting, handling and stacking of these Crane Fruehauf all-steel tipping containers, the container in this photograph being one of many being used by the National Carbonising Co Ltd on its Bulkliner service in conjunction with Crane Fruehauf skeletal semi-trailers. It has a capacity of 38.8 Cu yd and as part of a 28-ton-gvw outfit it can carry a payload of 17 tons. It is used to transport solid fuel on runs between London and Nottingham, backloacis normally comprising grain or scrap. A lifting frame at the front is attached to the container with twistlocks and is elevated by an Edbro twin-ram tipping gear to give an angle of hp up to 45deg. A front bolster is mounted on the container in the same way, while a special NCC double-section rear door comprises an upper door hinged vertically on one side and a tailgate that is suspended from it. The entire assembly can be swung open on the top door hinges.