)emolition my )usiness

Page 63

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

e reluctant tipper operator who akes an impressively thoughtful d thorough job of it • Gibb Grace, DAuE, CEng, MechE

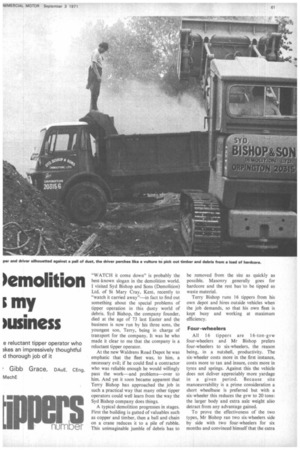

"WATCH it come down" is probably the best-known slogan in the demolition world. I visited Syd Bishop and Sons (Demolition) Ltd, of St Mary Cray, Kent, recently to "watch it carried away"—in fact to find out something about the special problems of tipper operation in this dusty world of debris. Syd Bishop, the company founder. died at the age of 73 last Easter and the business is now run by his three sons, the youngest son, Terry, being in charge of transport for the company. It was he who made it clear to me that the company is a reluctant tipper operator.

At the new Waldrens Road Depot he was emphatic that the fleet was, to him, a necessary evil; if he could find a contractor who was reliable enough he would willingly pass the work—and problems—over to him. And yet it soon became apparent that Terry Bishop has approached the job in such a practical way that many other tipper operators could well learn from the way the Syd Bishop company does things.

A typical demolition progresses in stages. First the building is gutted of valuables such as copper and timber, then a ball and chain on a crane reduces it to a pile of rubble. This unimaginable jumble of debris has to be removed from the site as quickly as possible. Masonry generally goes for hardcore and the rest has to be tipped as waste material Terry Bishop runs 16 tippers from his own depot and hires outside vehicles when the job demands, so that his own fleet is kept busy and working at maximum efficiency.

Four-wheelers

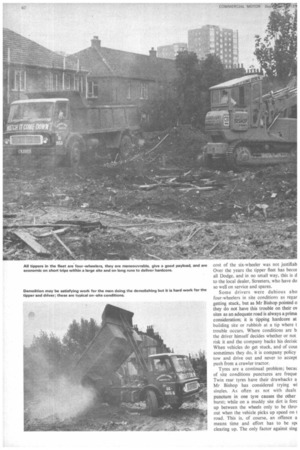

All 16 tippers are 16-ton-gvw four-wheelers and Mr Bishop prefers four-wheelers to six-wheelers, the reason being, in a nutshell, productivity. The six-wheeler costs more in the first instance, costs more to tax and insure, costs more in tyres and springs. Against this the vehicle does not deliver appreciably more yardage in a given period. Because site manoeuvrability is a prime consideration a short wheelbase is preferred but with a six-wheeler this reduces the gvw to 20 tons: the larger body and extra axle weight also detract from any advantage gained.

To prove the effectiveness of the two types, Mr Bishop ran two six-wheelers side by side with two four wheelers for six months and convinced himself that the extra cost of the six-wheeler was not justifiab Over the years the tipper fleet has becor all Dodge. and in no small way, this is d to the local dealer, Streeters, who have do so well on service and spares.

Some drivers were dubious abo four-wheelers in site conditions as regar getting stuck, but as Mr Bishop pointed o they do not have this trouble on their ov sites as an adequate road is always a prima consideration; it is tipping hardcore at building site or rubbish at a tip where t trouble occurs. Where conditions are b the driver himself decides whether or not risk it and the company backs his decisic When vehicles do get stuck, and of coin sometimes they do, it is company policy tow and drive out and never to accept push from a crawler tractor.

Tyres are a continual problem; becat of site conditions punctures are freque Twin rear tyres have their drawbacks a Mr Bishop has considered trying wi singles. As often as not with duals puncture in one tyre causes the other burst; while on a muddy site dirt is fore up between the wheels only to be duo' out when the vehicle picks up speed on 1 road. This is. of course, an offence a means time and effort has to be spt clearing up. The only factor against sing hat different wheels front and rear means ra parts to stook. The vehicles do not ry spares because of theft and ground arance problems and as all vehicles are in ch with base by radio-telephone a service can soon reach a stranded vehicle.

Mr Bishop considers the radio-telephone be a very necessary piece of equipment hout it any successful control of vehicle erations would, he considers, be )ossible. It costs about £190 to equip :h new vehicle he buys—not so much en taking into consideration the iipment's effectiveness.

wing gears Ile tipping part of the vehicle, the pto, lifting ram and the body give the least able of all. Tipping gears are Edbro inly, again because of good spares iilability; one is of the twin ram it-mounted type, an arrangement which proved reliable and gives good stability uneven ground.

he bodies themselves are all pose-built in steel with 10 cu yd deity. Ten yards is chosen because this ures that with hardcore, a normal load, plated weight is not exceeded. Mr Bishop's trucks, like many operators, are often stopped by DoE men and spot-weighed but so far he has not been issued with a GV9 for overweight. Some bodies have hinge-up panels which quickly increase the capacity to 15yd if a loose or light load such as timber is being carried.

On site the tippers are loaded very quickly by liyd crawler tractors and now and again large slabs of reinforced concrete or steel plates will pierce the floor. This is an accepted hazard—making the floor thicker would only help slightly but would increase weight and cost of the body. A patch is soon welded on back at the workshop.

All that site work does age the trucks and in spite of weekly washing the body in particular gets some very rough treatment. To keep up appearances, and Mr Bishop is a great believer in smartly turned out vehicles, the bodies are hand-painted frequently, perhaps twice yearly in the workshops.

One man, one vehicle • All vehicles are allocated to one driver only; over holidays or periods of sickness the vehicle stands idle. This, I thought, seemed wasteful but again Mr Bishop assured me he had tried it all ways and this way had proved the best. Any damage or adverse service history could be attributed to one driver without argument and without exception he has found that drivers treat the vehicle better when they know it is "their own".

All vehicles are bought new, kept for three years then sold. In this time an average tipper has covered some 100,000 miles and had the minimum of service problems, even so records show that the third year throws up significantly more problems than the first two. Apart from the weekly washing and greasing, every vehicle comes in on a rota for one complete day every month fOr a thorough check; as a result when the annual plating comes round nearly all get through first time. While I was in the office a truck came back from successful retest; it had failed originally on account of play in the power steering and a new power-steering ram had had to be fitted.

Power steering is specified on all trucks and is certainly desirable; on the sites I visited with drivers it would have been extremely difficult to steer without, and drivers I spoke to considered it very important. One point that did come to light with the good weather was the inadequate ventilation of the cab. Building rubble makes tremendous dust and even with the doors and windows closed tight the cab interior was invaded by dust. To keep cool the heater blower was used to draw in outside air and with it of course came the dust. It is a pity that manufacturers do not consider the drivers as important as the engine when it comes to air cleaning!

I left Mr Bishop as I had met him, answering the telephone. The tipper game is hectic and the vehicles are worked hard but, as Mr Bishop has shown, with proper facilities and supervision the vehicles can take it and earn a good living into the bargain.