TESTING TRUCKS AT 31 DEGREES UNDER

Page 85

Page 86

Page 87

Page 88

Page 89

If you've noticed an error in this article please click here to report it so we can fix it.

BY A. J. P. WILDING, MIMechE, MIRTE

BRITISH vehicle manufacturers are nowadays turning more and more towards the testing of vehicles in the arduous conditions to be found in remote parts of the world. It all started with cars being sent to places like East Africa for suspension and body-strength tests on un-made roads, to the Sahara for filter and sealing tests in sand and dust conditions and to such places as Canada and Northern Scandinavia for cold-running proving.

There is now a greater need for reliability in trucks and because conditions in many countries including Britain mean that a vehicle is operating near its limit for much of its life, the practice has spread into the commercial vehicle field. To get adequate proving in the UK, hundreds of thousands of miles are needed. But in certain areas the same knowledge can be obtained in only 5,000 miles or so or even less. In more leisurely times it may have been possible to spend long periods testing new designs but there are now very great pressures to complete development work quickly. And with modern methods of quantity production it is essential that inherent faults are cleared before a model is introduced.

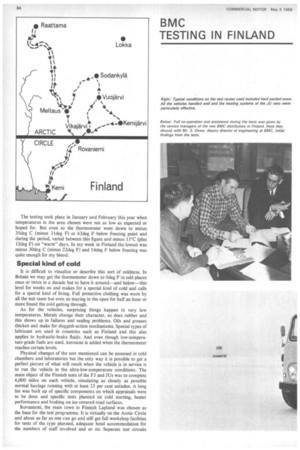

BMC has developed a number of important modifications to the F7 range c f medium-weight trucks in the past six months or so and as part of the proving tests of the finalized design, vehicles were taken to Finland for cold-climate tests. I accompanied the test team for the beginning of the exercise and besides the new-design components—engine and transmission primarily—the opportunity was taken to make a complete appraisal of the model and its suitability for markets such as Finland and Northern Scandinavia. At the same time, similar work was done on the 250JU light van which had been introduced about 18 months before but in this case the tests were primarily to assess the cold-climate performance. The testing took place in January and February this year when temperatures in the area chosen were not as low as expected or hoped for. But even so the thermometer went down to minus 35deg C (minus 31deg F) or 63deg F below freezing point and during the period, varied between this figure and minus I1°C (plus 12deg F) on "warm" days. In my week in Finland the lowest was minus 30deg C (minus 22deg F) and 54deg F below freezing was quite enough for my blood.

Special kind of cold

It is difficult to visualize or describe this sort of coldness. In Britain we may get the thermometer down to Odeg F in odd places once or twice in a decade but to have it around—and below—this level for weeks on end makes for a special kind of cold and calls for a special kind of living. Full protective clothing was worn by all the test team but even so staying in the open for half an hour or more found the cold getting through.

As for the vehicles, surprising things happen in very low temperatures. Metals change their character, so does rubber and this shows up in failures and sealing problems. Oils and greases thicken and make for sluggish-action mechanisms. Special types of lubricant are used in countries such as Finland and this also applies to hydraulic-brake fluids. And even though low-temperature-grade fuels are used, kerosene is added when the thermometer reaches certain levels.

Physical changes of the sort mentioned can be assessed in cold chambers and laboratories but the only way it is possible to get a perfect picture of what will result when the vehicle is in service is to run the vehicle in the ultra-low-temperature conditions. The main object of the Finnish tests of the FJ.and JUs was to complete 6,000 miles on each vehicle, simulating as closely as possible normal haulage running with at least 25 per cent unladen. A long list was built up of specific components on which appraisals were to be done and specific tests planned on cold starting, heater performance and braking on ice-covered road surfaces.

Rovaniemi, the main town in Finnish Lapland was chosen as the base for the test programme. It is virtually on the Arctic Circle and about as far as one can go and still get full workshop facilities for tests of the type planned, adequate hotel accommodation for the numbers of staff involved and so on. Separate test circuits were chosen for the two FJ 7-tonners and the 250JU vans (one a diesel, one a petrol) taken to Finland. The trucks ran on better-class roads between Kemi to the south of Rovaniemi and Soclankyla to the north while the vans had an almost circular circuit taking in Kemijarvi.

The truck route made a good day's work for a vehicle, measuring about 200 miles while the shorter van circuit-130 miles—could be covered two or three times in a day depending on conditions. In addition to the set routes all four vehicles were driven on one day to Raatama, some 150 miles north of the Arctic Circle to sec if even lower temperatures could be found but they were similar to those in Rovaniemi due to the "warming" effect of the Arctic Ocean which was relatively close at this point.

After arrival in Helsinki and before setting out on the 538-mile run to Rovaniemi, discussions were held with the local distributors for BMC products—Oy Veho Ab (Austin) and Oy Voimavaunu Ab (Morris)—to ensure that correct lubricants for the territory were being used and that legal requirements not included in the standard specification were being' met. Studded tyres were fitted to all the vehicles and one of the Rh had its clutch actuation system changed from air-assisted hydraulic to straight hydraulic—a conversion that had been developed by the local distributors. Each van had a full-height bulkhead to separate the driving area from the body of the van—a usual requirement for the area in question to conserve the heat in the front end—and Start Pilot starting aids were installed in the trucks together with alcohol evaporators for the air-brake systems. Apart from these points, the vehicles had the standard specification; and lubricants and hydraulic brake and clutch fluids were to the standard required in Finland.

About a week after the vehicles arrived in Rovaniemi, when the test team had settled into its routine, Stan Dews, now deputy director of engineering at BMC and Peter Wyatt, chief development engineer trucks, left for Finland to spend a week with the vehicles. I accompanied them and while in Helsinki they had further discussions with the two distributors to get the latest picture of service experience with the FJ and JU models. The service managers of the concerns—Bo Eklef of Veho and Kauko Ruutsalo of Voimavaunu—came to Rovaniemi with us to witness the tests. Needless to say, they were most interested and delighted that such an effort was being made to check the suitability of the designs in their market.

At minus 15deg C (plus 5deg F), the ambient temperature on the first morning that we went out on the test vehicles was higher than it had been previously. Starting after a night spent in the open was relatively easy using the standard equipment—excess fuel device and 12V electrics—but it -soon became obvious that something would need to be done about cab heating and defrosting. When warmed air did eventually get through the windscreen vents it could not be induced to get far enough up the screen to clear frost quickly from spreading into the driver's line of vision.

When the general temperature level in the cab increased, the screen cleared but with the heater working at its maximum, the temperature was only about 40deg F at Odeg F ambient. A minimum of 75deg F in the cab in this ambient condition was the target, so plans were made to get down to heater modifications as soon as possible.

The need for setting a target of 75deg F at Odeg F ambient was illustrated on subsequent tests, particularly on the day we went on the special long northern journey. Although outside temperature was not very low at Raatama, during the trip very low levels were encountered. This was particularly so on the return run which was made after dark. For much of this section ambient was minus 30deg C (minus 18deg F) the lowest we met in the week; the temperature had been as low as minus 35deg C on the journey from Helsinki with the vehicles and reached this figure again after we left. Cab temperature was very low, for all the return journey from Raatama, never rising above freezing point and in spite of our, protective clothing there was considerable discomfort particularly for the driver.

I drove one of the FJs for about 50 miles on the outward trip and I must say that I did not emjoy the experience over much. The truck handled well enough but it needed a good deal of experience to get complete confidence in the grip given by the tyre studs on the ice-packed and rutted roads. Avoiding on-coming traffic—fortunately very light—and keeping it clear of an undefined and possibly dangerous edge to the narrow roads was a delicate operation. This and very hilly terrain slowed progress and was not helped by a worsening of the clutch, gear change and two-speed axle change action as the temperature dropped. As the thermometer went farther and farther below freezing, things started to happen. The clutch and axle change became sluggish, then the gear unit in the speedodrive which adjusts the reading according to the rear-axle ratio selected ceased to operate, and so on.

In fairness to the design I should say that the BMC drivers who had become fully accustomed to the conditions and the vehicles made good progress and were not affected by the deficiencies which developed. They put up relatively high average speeds and drove to the limits set by the road and weather conditions.

As stated, there was no trouble in starting the engines of the test vehicles in temperatures down to minus 15deg C (plus 5deg F) and this was provided that the battery was in a full state of charge and that the ambient had not been appreciably below the figure in the "soak" period—while parked prior to starting. Starting below this temperature called for the use of Thermostart or Start Pilot aids and was often accompanied by vast amounts of smoke.

A vehicle had to be tow started only once while I was there and this was on the coldest morning, when the temperature was minus 25deg C (minus I 3deg F). Battery performance was considerably reduced in these low temperatures but on this occasion even with warm "slave" batteries, the engine of the Fl could not be brought into life—mainly due to a too-low cranking speed through oil drag. The other truck had been started (with some difficulty) using the Start Pilot and "slaves" and subsequent tests established that with the standard 12V electrical system a Thermostart enabled satisfactory cold starts to be made down to Odeg F.

But below Odeg F at the start, cranking speed was generally too low and tests with 24V electrics showed that there were considerable advantages with the modification. Satisfactory starts were made at Odeg F using only the excess fuel device with 24V and a single Thermostart enabled starts to be made at minus 23deg C (minus 10deg F) after a "soak" of 15 hours with temperatures down to minus 30deg C (minus 20deg F).

The local agents were recommending that a proprietary insulated t attery cover be fitted as standard for the trucks. This would have helped maintain the temperature in the cells but more important it would have overcome a problem that the batteries on the trucks were often too cold to accept a charge. Another cause of trouble on the electrical side was that the regulators did not operate correctly as they are in the cab of the FJ and therefore at a different temperature to that of the batteries.

Little mechanical trouble

In the 7,000-odd miles run by the F.Is there was virtually no mechanical trouble, most of what there was being caused by faulty seals (affected by the low temperatures), ice forming in the fuel-tank filters (from water in the tanks), ineffective alcohol evaporators in the air-pressure system (bad sealing again) and the like. But while the heater plugs of the JUs were most effective there was trouble with the starter solenoids on the diesel van due to the ingress of water.

It also became clear that different-model starters from the standard should be fitted to the petrol-engined vehicle for coldcountry use. One suggested by the Lucas engineer on the tests, was a M418 pre-engaged unit that would be satisfactory down to minus 40deg C (minus 40deg F) to be used in conjunction with an 11-plate battery as against the standard 7-plate types which made for difficult starting below minus 20deg C (minus 5deg F).

In the case of the diesel-engined JU, the M45 pre-engaged unit was satisfactory (except for the solenoid trouble) and a change to 9V heat plugs (giving more heat) gave good starts down to minus 30deg C (minus 20deg F).

One thing that the tests in Finland were invaluable for was the location of sources of draughts in the cabs. You do not need long to find the smallest hole letting in a shaft of minus 30deg C air. The Els were, however, remarkably free of draughts although there were one or two points calling for attention on the JUs.

Balanced braking is also of paramount importance in areas where roads are covered in packed ice for half the year. To see how the Els performed in this respect, Rovaniemi Airport's main runway was borrowed one morning when it was not otherwise required. The vehicles came out of their brake tests very well. When laden the FJs gave decelerations of up to 29 per cent before wheel locking and with a degree of front-wheel locking permitted, up to 33 per cent was obtained. Unladen, rear-wheel locking occurred at 18 per cent decelerations or better with 29 per cent recorded before front-wheel locking took place which showed that the balance between front and rear was reasonable and, of course, there would be an improvement with a light-laden valve if operators felt this was sufficiently desirable to warrant the extra cost.

It is one thing carrying out tests like those in Finland and another to convert the vast amount of information obtained into an easily digestible form. I am not trying to do this here and I have covered only the main points of the tests. I have not referred in any detail to fuel waxing because this must be a concern on all diesel vehicles in Finland and fuels marketed in this sort of area must take this into account.

Apart from those mentioned, there were checks on such things as snow and ice build-up on critical components, freezing of locks and window winders, smoke and noise levels and so on. During the tests general appraisals on all aspects of the designs were made and doing this well away from normal surroundings tended to make the BMC engineers present in Finland more critical of the design than an outsider can be. This is certain to have implications leading to improvements to the models independent of the cold-running requirements and of benefit to all operators generally.

As for Finland, before Stan Dews and Peter Wyatt returned to England there were further meetings with the service managers of the Finnish distributors to discuss the findings from the first two weeks of running.

It was agreed that cab heating and screen-defrosting facilities on the FJ were not totally adequate for the area. One or two improvised modifications were tried during the early tests with marginal results. A change to an 88deg C thermostat from an 82deg C unit gave a little improvement as did lagging the water pipes from the engine to the heater unit. But later in the tests the

heater-feed and return pipes were changed from 0.5in. diameter to 0.625in. diameter and this gave a considerable improvement and enabled the desired 75deg F general cab temperature at Odeg F ambient to be attained; this was a big step forward. Defrosting performance, however, remained inadequate and investigations were started to improve the air flow and study the possibility of incorporating a more powerful fan.

Any heating system changes decided will be made on all models for all countries but equipment to make starting in sub-zero temperatures easier would be included in a "cold-country package" of options. This would be likely to include an insulated battery cover—a designed unit not a fancy proprietary item as was being suggested—re-siting of the regulator, 24V electrics and specific starting aids although the last two points are still under investigation.

Clutch mechanism

The method of clutch actuation is also under review, not only for cold areas but for all countries. The long engagement delay and lack of control in low ambient temperatures were found to be unacceptable in Finland. The Veho-modified clutch mechanism worked well—there was a slight increase in effort and twice the travel—but this was not considered to be detrimental by BMC drivers who tried the design. I also preferred it, having criticized the air-assisted lay-out on previous occasions when used in this country.

Immediate action was taken on the difficulties of bad sealing due to hardening of rubber components. Suppliers have been contacted and asked to supply parts specifically developed for cold countries.

And the list could go on. Points were made on almost all components on the vehicles, most of them of a very minor nature and not warranting urgent change but they all add to the knowledge of BMC engineers which can be applied specifically to new models under development as well as introduced for the existing designs at the appropriate time.

Probably the most important thing about the exercise was the confidence for the future given to the BMC distributors and potential buyers in the area. BMC has shown that it is aware of troubles and that proving needs to be done in conditions likely to be met by its products when in service.

Both the Finnish distributors have praised BMC's action—to agents in other countries too—which illustrates the value of the proving tests in improving the image of the organization. The tests must also have done good for general marketing quite apart from the value to the engineering section. In the 7,000 miles covered by each of the vehicles there was not the slightest trouble with a major component even though they were driven very hard in very bad conditions. Very useful additional proof of the reliability of the current components used.