THE DESIGNER'S EYE ON MAINTENANCE COSTS.

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

Details of the Garner Chassis Which Have Been Adopted with a View to Wear-reduction and Ease of Maintenance.

18rHEN dealing, from time to time, with the products of Garner Motors, Ltd.—their passenger-convey'lug and goods-carrying vehicles and their bus-vansWe have had occasion to draw notice to the great amount of attention which the designers thereof have devoted to details which affect the cost of upkeep. We propose, in this article, to deal with these matters and other features of Garner chassis from the point of view of the maintenance engineer.

Neglect of lubrication is one of the most fruitful causes of high cost of upkeep, and although, neglect may usually be directly traced to some person, and that person may even be discharged, the damage will have been done and the cost of renewal of parts incurred. We were once impressed by a remark made by an engineer in charge of one of the largest fleets in the country, when the maker of a vehicle defended his lorry by saying that lubrication in certain parts had been neglected. The engineer said, "I know that there has been neglect, but our fleet is spread over many hundreds of miles of country, and I cannot be everywhere to see that things are not neglected. What I want are vehicles that will stand a fair amount of neglect with. out anything serious happening."

This would appear to be the. idea in the minds of the designers of the Garner, .as every care has been taken to provide an oiling system that will stand neglect.

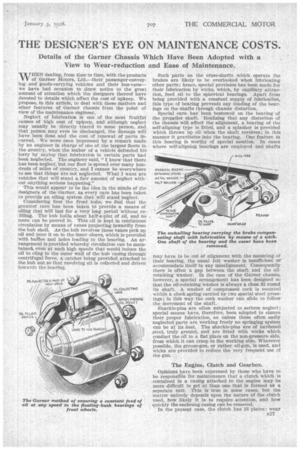

Considering first the front hubs, we find that the greatest care has been taken to provide a means of oiling that will last for a very long period without refilling. The hub holds about half-a-pint of oil, and no more can be poured in. This il is kept in continuouS circulation by means of vanes projecting inwardly from the hub shell. As the hub revolves these vanes pick up oil and pour it on to the inner sleeve, which is provided with baffles and holes leading to the bearing. An arrangement is provided whereby circulation can be maintained, even at such high speeds that would induce the oil to cling to the outer wall of the huh casing through centrifugal force, a catcher being provided attached to the hub nut so that revolving oil is collected and driven towards the bearing. Such parts as the cross-shafts which operate the brakes are likely to be overlooked when ltibricating other parts; hence, special provision has been made for their lubrication by wicks, which, by capillary attraction, feed oil to the spherical bearings. Apart from being provided With a constant supply of lubrication, this type of bearing prevents any binding of the beatings on the shifts through chassis distortion.

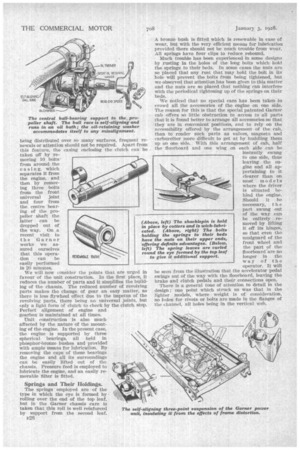

Special care has been bestowed on the bearing of the propeller shaft. Realizing that any distortion of the chassis will affect the alignment, a bearing of the self-aligning type is fitted, and a splasher is provided which throws up oil when the shaft revolves; in this manner it gravitates into the bearing. One feature, in this bearing is worthy of special mention. In eases where self-aligning bearings are employed and shafts

may have to be out of alignment with the mounting of their bearing, the usual felt washer is insufficient to– accommodate itself to any misalignment. Consequently there is often a gap between the shaft and the ollretaining washer. In the case of the Garner chassis, however, a special arrangement has been designed so that the oil-retaining washer is always a close fit round its shaft. A washer of compressed cork is mounted within a clock spring carried by two special steel pressings ; in this way the cork washer can slide to follow the movement of the shaft.

Shackle-pins are often subjected to serious neglect ; special means have, therefore, been adopted to ensure their proper lubrication, as unless these often sadly neglected parts are working freely no springing system can be at its-best. The shackle-pins are of hardened ,steel, truly ground, and are fitted with wicks which conduct the oil to a fiat place on the non-pressure side, A•om which it can creep to the working side. Wherever possible, the grease-gun, or rather oil-gun, is used, and wicks are provided to reduce the very frequent use of the gun.

The Engine, Clutch and Gearbox.

Opinions have been expressed by those who have to be responsible for maintenance that a clutch which is contained in a casing attached to the engine may be more difficult to get at than one that is formed as a separate unit. This is true in some cases, but the matter entirely depends upon the nature of the clutch used, how likely it is to require attention, and how quiekly the enclosing casing can be removed. In the present case, the clutch has13 plates ; wear 527

being distributed over so many surfaces, frequent renewals or attention should not be required. Apart from this feature, the casing enclosing the clutch can be taken off by removing 10 bolts' from around the ca sing, which separates it from the engine, and then by removing three bolts from the front universal joint and four from the centre bearing of the propeller shaft the

latter can be dropped out of the way: On .a recent visit to the Garner works we assured ourselves that this operation can be easily performed

in 20 minutes.

We will now consider the points that are urged in favour of the unit construction. In the first place, it reduces the number of parts and it simplifies the building of the chassis. The reduced number of revolving parts makes the change of gear an easy matter, as there is less flywheel effect due to the impetus or the revolving parts, there being no universal joints, hut only a light form of clutch to check by the clutch stop. Perfect alignment of engine and gearbox is maintained at all times.

Unit construction is also much affected by the nature of the mounting of the engine. In the present case, the engine is supported by three spherical bearings, all held in phosphor-bronze bushes and provided with ample means for lubrication. By removing the caps of these bearings the engine and all its surroundings can be easily lifted out of the chassis. Pressure feed is employed to lubricate the engine, and an easily removable filter is fitted.

Springs and Their Holdings.

The springs employed are of the type in which the eye is formed by rolling over the end of the top leaf, but in the Garner chassis care is taken that this roll is well reinforced by support from the second leaf.

E2S A bronze bush is fitted which is renewable in case of wear, but with the very efficient means for lubrication provided there should not be much trouble from wear. AU springs have four clips to reduce rebound.

Much trouble has been experienced in some designs by rusting in the holes of the long bolts which hold the springs to their beds. In some cases the nuts are so placed that any rust that may hold the bolt. in its hole will prevent the bolts from being tightened, but we observed that attention has been given to this matter and the nuts are so placed that nothing can interfere with the periodical tightening up of the springs on their beds.

We noticed that no special care has been taken to crowd all the accessories of the engine on one Side. The reason for this is that the special patented Garner cab offers so little obstruction to access to all parts that it is found better to arrange all accessories so that • they are in convenient positions, and to rely on the accessibility offered by the arrangement of the cab, than to render such parts as valves, magneto and carburetter more difficult, to get at by huddling them up on one side. With this arrangement of cab, half the floorboard and one wing on each side can be instantly swung to one side, thus leaving the engine and all appertaining to it clearer than on most models where the driver is situated behind the engine. Should it he necessary, t h e part swung out of the way can be entirely re moved by lifting It off its hinges, so that even the mudguard of the front wheel and the part of the floorboard are no longer in the way of the operator. It will be seen from the illustration that the accelerator pedal swings out of the waY with the floorboard, leaving the brake and clutch pedals and their connections open.

There is a general tone of attention to detail in the design ; one point which struck us was that in the lighter models, where weight is of consideration, no holes for rivets or bolts are made in the flanges of the channel, all holes being in the vertical web.