Novelties in Spring Design

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

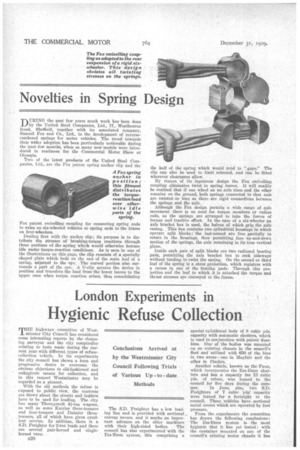

DURING the past few years much work has been done by the United Steel Companies, Ltd., 17,, Westbourne Road, Sheffield, together with its associated company, Samuel Fox and Co., Ltd., in the development of reversecambered springs for motor vehicles. The trend towards their wider adoption has been particularly noticeable during the past few months, when so many new models were introduced in readiness for the Commercial Motor Show at Olympia.

Two of the latest products of the 'United Steel Companies, Ltd., are the Fox patent spring anchor clip and the Fox patent swivelling coupling for connecting spring ends to axles on six-wheeled vehicles or spring ends to the frame on four-wheelers.

Dealing first with the anchor clip; its purpose is to distribute the stresses of breaking-torque reactions through those portions of the spring which would otherwise become idle under torque-reaction conditions. As is seen in one of the illustrations en this page, the dip consists of a specially shaped Plate which beds on the end of the main leaf of a sprite, adjacent to the eye. The curved portion also surrounds a part of the eye. A U-clip secures the device in position and transfers the load from the lower leaves to the upper ones when torque reaction arises, thus consolidating

the half of the spring which would tend to "gape." The clip can also be used to limit rebound, and can be fitted wherever clearances allow.

By reason of its ingenious design the Fox swivelling coupling eliminates twist in spring leaves. It will readily be realized that if one wheel on an axle rises and the other remains on the ground, both springs connected to that axle are twisted so long as there are rigid connections between the springs and the axle. • Although the Fox design permits a wide range of axle movement there is no need for torque members or radius rods, as the springs are arranged to take the forces of torque and tractive effort. In the ease of a six-wheeler an axle bracket box is used, the halves of which grip the axle casing. This box contains two cylindrical housings in which operate split blocks ; the last-named are free partially to rotate in the housings thus permitting free up-and-down motion of the springs, tha axle remaining in its true vertical plane. Inside each pair of split blocks are two radiused bearing pads, permitting the axle bracket box to rock sideways without tending to twist the spring. On the second or third leaf of -the spring is a stout projection, which registers with a recess in one of the bearing pads. Through this projection and the leaf to which it is attached the torque and thrust stresses are conveyed to the frame.