Contributions from Drivers and Mechanics.

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY for the Best Communication Received, and One Penny a Line of ten words for any thing else published.

Drivers of commercial-motor vehicles and tractors, and mechanics and foremen of garages or shops, are invited to send short contributions on any subject which is likely to prove of interest to our readers. Workshop tips and smart repairs ; long and successful runs ; interesting photographs : all ore suitable subjects. Send a post-card, or a letter, or a sketch to us—no matter how short, or how written, or how worded. We. wilt " knock it into shape" and .prepare sketches, where necessary, before publication. The absence of a sketch does not disqualify for a prize. When writing use one side of the paper only and mention your employer's name as a guarantee of bona fides. Neither your own nor your employer's name will be disclosed. Payment will be made immediately after publica t ion. Address your letters to The Editor, THE

COMMERCIAL MOTOR, 7-15, Roseberv Avenue, London, E.C.

Tool for Withdrawing Boiler Tubes.

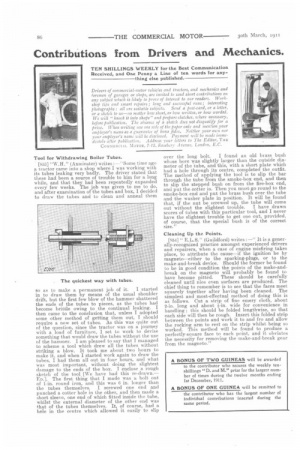

[853] "W.11." (Axminster) writes : —"Some time ago a tractor came into a shop where I was working with its tubes leaking very badly. The driver stated that these had been a source of trouble to him for a long while, and that they had been repeatedly expanded every few weeks. The job was given to me to do, and after examination of the tubes and box, I decided to draw the tubes and to clean and anneal them so as to make a permanent job of it. I started in to draw them by means of the usual shoulder drift, but the first few blow of the hammer shattered the ends of the tubes to pieces, as the tubes had become brittle owing to the continual leaking. I then came to the conclusion that, unless I adopted some other method of getting them out, I should require a new set of tubes. As this was quite out of the question, since the tractor was on a journey with a load of furniture, I set to work to devise something that would draw the tubes without the use of the hammer. I am pleased to say that I managed to scheme a tool which drew all the tubes without striking a blow. It took me about two hours to make it, and when I started work again to draw the tubes, I had them all out in four hours, and what was most important, without doing the slightest damage to the ends of the box. I enclose a rough sketch of the tool [We have had this re-drawn.— En.l. The first thing that I made was a bolt out of 1-in, round iron, and this was 6 in. longer than the tubes themselves. I screwed one end and punched a cotter hole in the other, and then made a short sleeve, one end of which fitted inside the tube, whilst the external diameter of the other end was that of the tubes themselves. It, of course, had a hole in the centre which allowed it easily to slip over the long bolt. I found an old brass bush whose bore was slightly larger than the outside diameter of the tube, and this, with a short plate which had a hole through its centre, completed the outfit. The method of applying the tool is to slip the bar through the tube from the smoke-box end, and then to slip the stepped bush on from the fire-box end, and put the cotter in. Then you must go round to the smoke-box end and put the brass bush over the tube and the washer plate in position. It will be found that, if the nut be screwed up, the tube will come out without the slightest trouble. I have drawn scores of tubes with this particular tool, and I never have the slightest trouble to get one out, provided, of course, that the special bush is of the correct size."

Cleaning Up the Points.

{S54] " E.L.S." (Guildford) writes :—" It is a generally-recognized practice amongst experienced drivers and repairers, when a case of engine misfiring takes place, to attribute the cause—if the ignition be by magneto—either to the sparking-plugs, or to the make-and-break device. Should the former be found to be in good condition the points of the make-andbreak on the magneto will probably be found to have become pitted. These should be carefully cleaned until nice even surfaces are produced. The chief thing to remember is to see that the faces meet squarely together after having been cleaned. The simplest and most-effectual method of doing this is as follows. Cut a strip of fine emery cloth, about 2-in, long and about i-in. wide for convenience in handling; this should be folded lengthwise, so that each side will then be rough. Insert this folded strip between the points and work it to and fro and allow the rocking arm to rest on the strip whilst being so worked. This method will be found to produce a perfectly-square face to each point, and it obviates the necessity for removing the -make-and-break gear from the magneto." [8.55] " R.V." (Peckham) writes :—" I enclose you a tough sketch of a very-useful little tool that I have made for shop use out of an old smooth file. You will no doubt redraw the sketch. [We have done so..—Eral Any old file of suitable size is good enough for the job, and if it be softened, cut off, drilled and trimmed to shape, a most-useful hand-vice can readily be made it the cost of a few pence. Two fin, bolts are used, as shown in the sketch ; one is screwed in to the top member of the vice, whilst the other registers in the bottom member by means of a square neck and holds on to the top half with a nut. It will be seen that a grip can readily be obtained by suitable adjustment of these two bolts."

Cork Insets for Clutches.

[856] " S.I." (Blackburn) writes :—" Some time ago we had considerable trouble with a fierce clutch on a 24-h.p. 2-ton lorry. We tried new leathers, as well as all sorts of dressings for the leathers, but we could not discover any cure. Our last effort was with cork insets, and these cured the trouble. We carried out the alteration in the following manner. We took off the clutch leathers, which were fastened with countersunk screws, and we then punched six holes in each with a saddler's punch. The holes were 'punched from the side of the leather which backed on to the clutch ; this left a slightly-taper hole, with its largest diameter inwards. We then got about a. dozen corks, all of the same size, and carefully picked the best of these. By fitting them into an old bush we were able to cut them off square with a thin sharp knife. By carefully keeping to the edge of the bush we were able to cut exactlyparallel slices of cork, all of which were 1-16th-in. thicker than the clutch leather. We then put back the leathers on to the clutch, inserting the corks as we went on. At first we were inclined to think that this dodge, although it might be efficient for the time, would not last ; but to our surprise the driver reported to us that he had had no trouble over the whole of the 1,500 miles over which he drove the machine, until it was finally sold out of our district. Trouble with that fierce clutch was entirely cured at a very-small expense, and the driver told us that, after the cork insets were fitted, the clutch was so sweet that he was able to take his foot off the clutchpedal and to let the clutch go in 'anyhow."