HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble,

$87.—Removing the Clutch Springs On the Morris Light and Heavy Chassis.

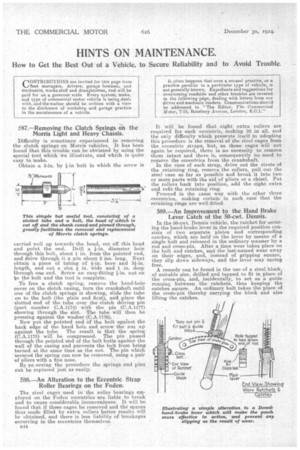

Difficulty is sometimes experienced in removing the clutch springs on Morris vehicles. It has been found that this trouble can be obviated by using the special tool which we illustrate, and which is quite easy to make.

Obtain a 3-in. by I in bolt in which the screw is carried well up towards the head, cut off this head and point the end. Drill a diameter hole through this bolt, about 1 in. from the pointed end, and drive through it a pin about 2 ins. long. Next obtain a piece of tubing of i-in. bore and 31-in. length, and cut a slot in. wide and 1 in. deep through one end. Screw an easy-fitting nut on ho the bolt and the 001 is complete.

To free a clutch spring, remove the hand-hole cover on the clutch easing, turn the crankshaft until one of the clutch springs is showing, slide the tube on to the bolt (the plain end first), and place the slotted end of the tube over the clutch driving pin (part number C.A.1174) with the pin (C.A.1177) showing through the slot. The tube will then be pressing against the washer (C.A.1176). Now put the pointed end of the bolt against the back edge of the hand hole and screw the nut up against the tube. The result is that the spring (C.A.1175) will be compressed. The pin passed through the pointed end of the bolt butts against the wall of the casing and prevents the bolt from being turned at the same time as the nut. The pin which secured the spring can now be removed, using a pair of pliers with a fine nose. By re sersing the procedure the springs and pins eats be replaced just as easily.

588.—An Alteration to the Eccentric Strap Roller Bearir gs on the Foden.

The steel cages used in the roller bearings employed on the Foden eccentrics are liable to break and to cause considerable inconvenience. It will be found that if these cages be removed and the. spaces thus made filled by extra rollers better results will be obtained, and there is less liability of breakages occurring in the eccentrics themselves.

n44 It will be found that eight extra rollers are required for each eccentric, making 32 in all, and the only difficulty which presents itself in adopting this procedure is the removal of the steel cages from the eccentric straps, but, as these cages will not again be required, there is no necessity to remove them intact and there is, consequently no need to remove the eccentrics from the crankshaft.

In the case of each strap, drive out the rivets of the retaining ring, remove the rollers, pull out the steel case as far as possible and break it into two or more parts with the aid of pliers or a chisel. Put the rollers back into position, add the eight extra and refit the retaining ring.

Proceed in the same way with the other three eccentries, snaking certain in each ease that the retaining rings are well fitted.

589.—An Improvement to the Hand Brake Lever Catch of the 50-cwt. Dennis.

In the 50-ewt. Dennis vehicle, the ratchet for securing the hand-brake lever in the required position consists of two separate plates and corresponding catches, which are held on the lever by means of a single bolt and released in the ordinary manner by a rod and cross-pin. After a time wear takes place on the bolt and catches, and the last-named wear away• on their edges, and, _instead of gripping square, they slip down sideways, and thelever may spring free.

A remedy can be found in the use of a steel block, of suitable size, drilled and tapped to fit in place of the cross-pin, and, incidentally, to aet as a guide running between the ratchets, thus keeping the catches square. An ordinary bolt takes the place of the cross-pin thereby carrying the block and also lifting the catches.