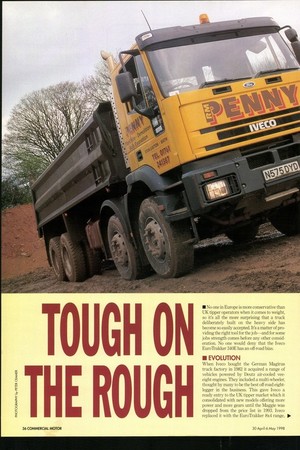

TOUGH ON E ROUGH No vehicle is perfect, but if

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

you're looking for a rugged tipper to withstand the rigours of site work, you really ought to check out the Iveco EuroTrakker... unlike its predecessor, the EuroTrakker was built in Spain where they know all about building trucks able to withstand harsh operating conditions. We thought that 345hp was a lot to squeeze out of just 9.5 litres, but were impressed with the level of torque, which is certainly more than is available from the 11.6-litre unit used in Daf's 85.330 8x4 chassis. Highly rated small capacity engines have rarely delivered good fuel consumption in CM tests, but there's always the exception to the rule Iveco's overall returns of 8.26mpg were not as bad as some, but failed to match either the 9.23mpg of ERF's EC 10.35 or the 8.6mpg of Daf's 85.330. Although our test vehicle was specified with a faster 3.79:1 final drive ratio than the 4.23:1 listed as standard it never broke sweat restarting on a 1:3 test hill. Overall gearing seemed to suit motorway running better than A-road• driving, but it returned journey times of just below the average The engine was not short of mid-range power, and the broad band of useful torque from 1,100rpm meant that most driving was accomplished using only the top six ratios, even though the Twin Splitter installation was not the smoothest we had come across. The ride was good with the suspension levelling out all minor bumps, and the handling was reassuringly stable.

However, some maladjustment of the brakes caused a drift to the right under extreme braking he exhaust brake made a lot of noise but didn't do much unless engine speed was allowed to climb to about 2,400rpm. The cab's bottom step was lower than some of the competition's but it did swing away to avoid damage. A step below the front grille was prone to rattle, which became irritating by the end of the day. Inside, the black and grey trim was typically bland but the instruments were clear It was quite a roomy cab with plenty of space for stowage, but a little more thought might have made it even better • No one in Europe is more conservative than UK tipper operators when it comes to weight, so it's all the more surprising that a truck deliberately built on the heavy side has become so easily accepted. It's a matter of providing the right tool for the job—and for some jobs strength comes before any other consideration. No one would deny that the Iveco EuroTrakker 340E has an off-road bias.

• EVOLUTION When Iveco bought the German Magirus truck factory in 1982 it acquired a range of vehicles powered by Deutz air-cooled veeeight engines. They included a multi-wheeler, thought by many to be the best off-road eightlegger in the business. This gave Iveco a ready entry to the UK tipper market which it consolidated with new models offering more power and more gears until the Maggie was dropped from the price list in 1993. Iveco replaced it with the EuroTrakker 8x4 range, headed by the 340E which was specifically designed to cope with demanding muckaway work for the construction industry. The designation relates to the design weight so there's a lighter 320E model powered by the same 9.5-litre lump producing 345hp at 2,200rpm. Alternatively, the 340 can be equipped with a 13.8-litre engine which delivers 370hp.

The 9.5-litre engine produces exceptional torque for its size—just right for mud plugging. Large big ends and journals ensure it can deliver the 1,0691bft of torque time after time: having the fuel pump mounted on one side and the compressor on the other makes maintenance easier.

The 340's strong chassis is fitted with hubreduction axles for maximum ground clearance while the rear bogie has two-spring cantilever suspension for maximum articulation and traction. The axles incorporate crossaxle and inter-axle diff-locks to maintain drive on site. With front axles plated at 15 tonnes, it shares the same parabolic springs as the lighter version.

Both Eaton's 12-speed constant-mesh Twin Splitter box and ZF's 16-speed heavy-duty synchromesh transmission are available. EuroTrakker takes its cab from the EuroTech tractor; all cabs receive the full zinc plate anti-corrosion treatment and some of the exterior panels are made from SMC materials to help reduce the unladen weight.

Extra cab protection includes a three-part steel bumper, light grilles and bottom steps that fold back if knocked. The cab is fully suspended and the driver is supplied with an Isringhausen air-suspension seat. Electric windows are standard but trim is well suited to the tipper environment.

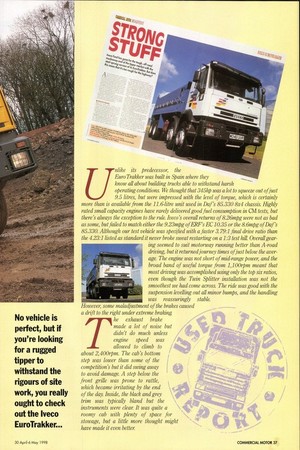

• OPERATORS Tommy Smyth has had a tipper operation in Birmingham for the past 10 years. He started with Magirus Deutz and Leyland Constructors; today he runs 17 eight-wheelers across the Midlands. Smyth uses them to move crushed products and aggregates and for bulk excavation work. "The Magirus had an air-cooled engine, strong back axle and a good gearbox," he says. "It was as strong as a dump truck. The new Ivecos are just as good and they have good ground clearance. I bought three Volvo FlOs because they were cheap, but all my other trucks are Ivecos. I have seven EuroTrakker 340s.

"The Volvos can't do the same work we use them for," he adds. "They are N, P and R-registrations, specified with light steel bodies from Welford with Hyva front-end tipping gear. The payload is about 20 tonnes. They're doing about 6mpg, including a lot of town running and site work; that's not bad. They're no more expensive than anything else, if you get the right deal.

"I normally keep them for five or six years and probably break them for spares," he says. "We cover over 80,000 miles a year, so they will have done their share of work by then. I don't sell many trucks on. As far as major components go, the EuroTrakkers have been no trouble up to now. We do all our own servicing and we have hardly bought anything other than normal service items. The drivers like the Twin Splitter box fitted to the two Nreg trucks. They work like a semi-automatic. On the later ones we have the 16-speed ZF synchromesh. They're both just as reliable as each other. The day cabs are a good size.

"I'd like to say that dealer back up is good, and they look after me," says Smyth. "We have overnight delivery on parts and the couple of times that we have called on them for breakdowns they were very quick to turn out From day one we have complained about the brakes being noisy and just now we have a problem with brake wear. Those on the first and second steer axles, and sometimes the third axle, are wearing out in less than 35,000km. When we looked at the linings through the inspection hole the top lining appeared to be hardly worn at all. All the wear is occurring on the bottom lining which can't be seen unless the back plate is removed. By the time the light comes up on the dash it is too late damage has already been done to the drums.

"My local dealer in Birmingham says it is fair wear and tear," he says. "It's fairly fiat around here but if I was working in Wales I would be out of business—it's going to cost 0,500 per vehicle. Drums and linings last at least twice as long on my older vehicles: I'm just not satisfied.

"On the Tuesday morning Guests, the local dealer, contacted the manufacturer. Iveco tells us that if a material fault is the reason for the accelerated wear of the brakes then that will be covered by warranty Only one vehicle of the three is believed to have a problem but an engineer was dispatched to inspect all three and will produce a full report. Iveco says the EuroTrakker has been in service for several years and it is not aware of a general problem of this type affecting the range."

Smyth has seven more EuroTrakkers on order so Iveco is naturally keen to bring the matter to a mutually satisfactory conclusion. Iveco's initial reaction is to replace the linings and damaged drums. The manufacturer says that uneven wear between axles is not unusual on eight-wheelers but it will examine the load sensing.

The lining wear warning should light up before damage occurs. The engineer may recommend an extra heavy duty maintenance cycle, which includes removal of the back plates, if Smyth's operation warrants it.

The Clancy Group has been in business as a major civil engineering contractor for more than 40 years. The substantial part of its present operation is with many of the new, privately owned water companies and other utilities. In addition to a large amount of plant the company operates a big mixed fleet of trucks which includes more than 100 Iveco tippers, as well as a number of Volvos and Seddon Atkinsons.

Group director Mike Revell oversees the organisation's transport and plant operations from the company's headquarters at Harefield, Middlesex. "We have had dealings with Iveco for 20 years and operated two EuroTrakkers for the past three years," he says. "We've just added a further four to the fleet. We buy them because they're very reliable, they're good on fuel, maintenance costs are low and we get good backup from Iveco.

"The chassis are fitted with lorry-mounted cranes and grabs," he adds. "We use either IMF or Atlas so by the time the Thompson steel bodies have been added the payload is down to just over 16 tonnes. They run loaded almost all of the time and return 6.5 to 7mpg. We took the Eaton Twin Splitter box on the first two vehicles but specify the 16-speed ZF box now. There's no difference in reliability. The only failures we have suffered were with clutches. We were running into trouble at about the 1 , km mark but Iveco stood by us They changed over to —_ ceramic friction material which appears to have sorted out the problem.

"The engine has been no trouble at all," says Revell, "but there were a few minor electrical faults at first. The cab is excellent—drivers like the room and the comfort from a very good suspension seat. From a driver's perspective they could be better. There were no complaints about power, or traction, but large mirrors can create a blind spot to threequarter forward vision. From the high driving position the area close to the nearside door remains out of view.

"The low steps are knocked and the pivot action is not really sufficient to withstand heavy off-road conditions, he reports. "Warning lights sometimes come on for no apparent reason. Constant coming and going causes the seat covers to wear while minor items of plastic trim shake loose. The backing on external mirrors needs to be more substantial to withstand the rigours of operation. The bodies are covered by a five-year warranty but we don't keep the trucks that long. We have always had good residuals on Iveco trucks.

"We do all our servicing in house and carry an imprest stock," says Revell. "The EuroTrakker is ruggedly built, it has excel lent ground clearance and access is good for maintenance. Any problems we have had with any Iveco vehicle have been sorted out quickly. The backup is superb."

Penny Plant Hire, based at Ston Easton on the borders of Avon and Dorset, has been established for almost 40 years Commercial fitter Stuart McArdle is close to the day-today problems that arise with a fleet of 18 vehicles which includes six EuroTrakker eight-wheel tippers and one skip loader.

"They're used on heavy muckaway work and spend a lot of time on site, so we don't pay too much attention to fuel consumption," he says "The tippers have light, high-tensile steel bodies and can handle a payload of about 18.5 tonnes. We've had the EuroTrakkers for about three-and-a-half years now and the oldest has about 220,000km on the clock.

"They're not bad on tyres but we have had a lot of problems with the brakes," McArdle reports. "The leading shoes wore down to.the rivets while the others remained almost untouched. There has been a mod and they're now a lot better, but it did not entirely cure the problem. The truck came with a mix of brakes on the axles and not always in the same position. The trouble there is that they use different brake shoes from one another. We've had two turbo failures where the nut dropped off the impeller. Diesel pipes are prone to internal pulsing and if they lie alongside another one then it can lead to chafing. The clutch thrust bearing is a bit weak and can pull out of the flywheel. On just one of the EuroTrakkers we had to replace two of the differential units; but Iveco did pay out on that one.

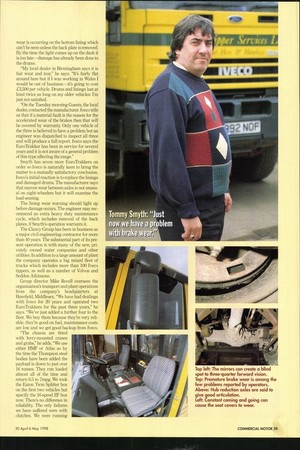

"Electrics are not bad, except for the warning panel which has just too many wires going to it," he concludes. "With the rough work the vehicles are put through they can shake loose. The cabs are quite good overall. If the seat's air dump packs up then that can lead to extra wear on the seat cover as the driver squeezes in under the wheel. We did have a lot of cracked screens—they failed above the nearside grille hinge. I think Iveco modified the clearance on the surrounds" • DEALERS Robin Hulse is assistant sales manager for franchised Iveco dealer Sandersons at Leicester. He says they probably sell fewer 340s than the lighter 320 EuroTrakker: "The 340 is not an ownerdriver's truck; they all go into company fleets. It's a very sturdy vehicle designed with hubreduction axles to give good articulation and ground clearance for muckaway work. Every one we have sold has had the 9.5-litre engine: it's quite powerful enough and doesn't have the weight penalty of the 13.8-litre engine.

"You used to have to pay extra for a synchromesh transmission on a vehicle of this type but you can have it for the same price as the constant-mesh box," he says. "We find demand is about the same for both. The only extras we're asked for are a radio and reverse bleeper. We also fit Tracker systems. Traction control is listed but we've never been asked for it. We're buildingup our used truck sales business and often carry a stock of up to 20 vehicles, but I can't remember ever seeing a EuroTrakker in for resale."

• SUMMARY The day the perfect vehicle is built there will be operators lining up at the dealer's door. We don't see it happening just yet, but the EuroTrakker is built to work hard in heavy off-road conditions and the chassis, axles, engine and transmission stand up to the task well. It may be too much to ask for items such as self-adjusting brakes to work as well in muddy off-road conditions as they do on road.

Service lamps that are prone to light up for no apparent reason do not help the cause; seats, trim and mirror backs could be more substantial. But overall the EuroTrakker looks like a sturdy tool for a tough job.

by Bill Brock SPECIFICATIONS MODEL: Iveco Eurotrakker 340E34H 8x4 rigid chassis with day cab. Design G1VV: 44 tonnes. Design GVW: 32 tonnes. Manufacturer: Iveco Ford Truck, Iveco Ford House, Station Road, Watford WD1 1SR.

ENGINE: Iveco 8460, Euro-2, charge-cooled diesel. Cylinders: Six, in line. Capacity: 9.5 litres. Maximum net power: 340hp (254kW) at 2,200rpm. Maximum net torque: 1,450Nm (1,06916ft) at 1,200rpm.

TRANSMISSION: Eaton TS 16612 12-speed constant mesh. Single dry plate clutch, 406mm diameter. Final drive: 4.23:1 as standard. BRAKING SYSTEM: Dual-circuit, full-air system with Wabco Cat-1 ABS and air dryer.

Parking: Spring brake actuators.

STEERING: ZF 80998, hydraulic power assistance.

CHASSIS: Ladder construction with riveted and bolted cross-members. Suspension: Front, parabolic; rear, parabolic cantilever with anti-roll bars all round.

Wheelbase: 5.58m to 7.2m.

Wheels and tyres: Front, 22.5 rims with 315/80R22.5 tyres; rear, 12R22.5 tyres. Fuel tank: 300 litres.

ELECTRICAL SYSTEM: 24V, 2x143Ah batteries with 55A alternator.

PARTS PRICES Manufacturer's prices (retail ex-VAT) Laminated windscreen £170.61 Injector set (six, service exchange) £361.80 Piston liner set (six) £753.48 Rear spring brake chamber £219.23 Complete headlamp unit £180.80 Wiper blades (complete set) £21.98 Engine oil filter £9.32 Complete clutch assembly (exchange) £450.47 Door mirror (complete) £65.17 WORKSHOP TIMES Manufacturer's standard workshop hours Remove and replace clutch assembly 11.2 Remove and replace one injector 0.5 Replace head gasket 9.8 Replace brake shoes/pads, front and rear 8.2 Remove and replace engine 20.5 Remove and replace gearbox 9.9 Renew engine oil filter(s) 0.3 ROADTESTS EuroTrakker 340E34H CM 4-10 July 1996