New packaged tipper service

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

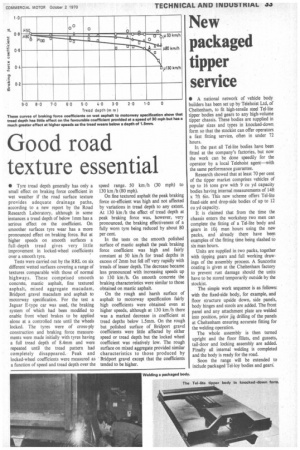

• A national network of vehicle body builders has been set up by Telehoist Ltd, of Cheltenham, to fit high-tensile steel Tel-lite tipper bodies and gears to any high-volume tipper chassis. These bodies are supplied in popular sizes and types in knocked-down form so that the stockist can offer operators a fast fitting service, often in under 72 hours.

In the past all Tel-lite bodies have been fitted at the company's factories, but now the work can be done speedily for the operator by a local Telehoist agent—with the same performance guarantee.

Research showed that at least 70 per cent of the tipper market comprises vehicles of up to 16 tons gvw with 9 cu yd capacity bodies having internal measurements of 14f1 x 7ft flirt. This new scheme offers Tel-lite fixed-side and drop-side bodies of up to 12 cu yd capacity.

It is claimed that from the time the chassis enters the workshop two men can complete the fitting of a Tel-lite body and gears in 10+ man hours using the new packs, and already there have been examples of the fitting time being slashed to six man hours.

Units are supplied in two packs, together with tipping gears and full working drawings of the assembly process. A Suncorite coating is given at the Cheltenham factory to prevent rust damage should the units have to be stored temporarily outside by the stockist.

The simple work sequence is as follows: with the fixed-side body, for example, and floor structure upside down, side panels, body hinges and stools are added. The front panel and any attachment plate are welded into position, prior jig drilling of the panels at Cheltenham ensuring accurate fitting for the welding operation.

The whole assembly is then turned upright and the floor fillets, end gussets, tail-door and locking assembly are added. Finally all internal welding is completed and the body is ready for the road.

Soon the range will be extended to include packaged Tel-by bodies and gears: