Transport Notes for

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

Those Who Run Bedfords

By F. S. Groom

Editor, " The Bedford Transport Magazine."

FROM time to time the Minister of Supply and other responsible members of the Government have given details of the immense war effort now being made by British industry. The nation is arming on a gigantic scale, and we must face up to the fact that, while all this is going on, other things are bound to suffer.

One of those things, it seems fairly certain, is the delivery of ordinary commercial vehicles to transport users. The resources of the' motor trade are bunched solidly behind the national effort. Materials, as well as production facilities, are being absorbed at an unprecedented rate to feed the fighting forces, and normal activities are being inevitably elbowed out of the picture.

In other words, " non-availability," a term which would make A. P. Herbert writhe if he heard it, is likely to make many more of us writhe during the next few months. Vehicles for ordinary domestic use just will not be available in anything like the required quantities.

This sounds like a black picture: rather like offering up something for the transport user to brood over before he sends out for a jug of hemlock. But it is not meant that way. I am stressing the facts simply because now is the best time to prepare for them.

In plain terms, commercial-vehicle owners are going to be short of transport unless the trucks they are running now be still running in the months to come. We must " keep them alive," as it were, and the man who believes in regular maintenance looks like having the last laugh.

This care and routine maintenance probably comes easier to the fleet user than it does to the small man. For one thing, he can afford to run a maintenance staff; and, for another, it is possible for him to have one truck at a time in for overhaul while still keeping a number of vehicles on the road.

This plan is already adopted by many big users, and it is one which cannot be too strongly recommended, especially now. For the owner who does not undertake his own service work there are dealer service stations all over the country, equipped not only with the right tools, but with specialized knowledge of the vehicles.

Many of these service stations can assist the small man by carrying out service work in the hours when the truck is off the road, The soundest advice I can give to any user who has not already arranged a regular and comprehensive system of maintenance is—go to your dealer and find out how he can help you. Do not put it off until it he too late. Your living may

depend on the preparation you make now.

There arc, of course, lots of ways in which the owner can help himself. One of the most important is summed up in the old proverb about the stitch in time. Keep an eye on the condition of your vehicles; in short, make sure that the little jobs which need doing are done before they develop into big ones.

I have already dealt with a number of routine maintenance tips which come under this heading. Here are one or two more— this time dealing with some of the cab and body mounting bolts.

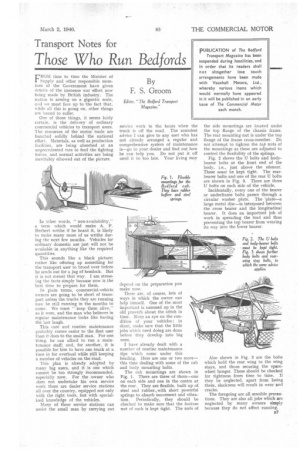

The cab mountings are shown in Fig. 1. There are three of them—one on each side and one in the centre at the rear. They are flexible, built up of steel and rubber„with short powerful springs to absorb movement and vibration. Periodically, they should be checked to make sure that the bottom nut of each is kept tight. The nuts of

the side mountings are located under the top flange of the chassis frame. The rear mounting nut is under the top flange of the frame cross-member. Do not attempt to tighten the top nuts of the mountings as these are adjusted to control the flexibility of the springs.

Fig. 2 shows the U bolts and bodybearer bolts at the front end of the body, i.e., just above the silencer. These must be kept tight. The rearbearer bolts and one of the rear U bolts are shown in Fig. 3. There are three U bolts on each side of the vehicle.

Incidentally, every one of the bearer or underframe bolts passes through a circular washer plate. The 'plate—a large metal disc—is interposed between the cross bearer and the longitudinal bearer. It does an important job of work in spreading the load and thus preventing the top bearer from wearing its way into the lower bearer.

Also shown in Fig. 3 are the bolts which hold the rear wing to the wing stays, and those securing the sparewheel hanger. These should be checked for tightness from time to time. If they be neglected, apart from losing them, slackness will result in wear and cracks.

The foregoing are all sensible precautions. They are also all jobs which are neglected by many owners simply because they do not affect running.