Machine Tools for Motor Manufacturers.

Page 3

Page 4

If you've noticed an error in this article please click here to report it so we can fix it.

A Few of Alfred Herbert's Most Useful Models.

As the visitor to the Olympia Show examines some of the very-accurately-machined parts which are embodied in the numerous exhibits, he may well think of the advance which has been made in the design of machine tools the evolution of these tools has given to us the means of producing very excellent results. As far as motor manufacturers are concerned, one of the most useful of machine tools is the turret lathe, which is so largely employed for bar and chuck work. There are two classes of work which may be done on a turret lathe, viz. : that in which the work is completed from the straight bar ; and that which is machined from separate forgings, or blanks that have previously been sawn from a bar of large diameter. Bar work varies little in diameter, but considerably in length, and, therefore, a machine for dealing with it needs only a small amount of cross traverse. Chuck work, however, usually varies more in diameter than in length, so that a considerable amount of cross traverse is necessary for this type of machine tool. The most efficient machine for chuck work must be fitted with a saddle, similar to that which is found on the ordinary, engine lathe. On a machine which is designed for bar work, special provision must be made to support the overhang of the work against the pressure from the cutter, and some efficient and rigid " steady " must be provided.

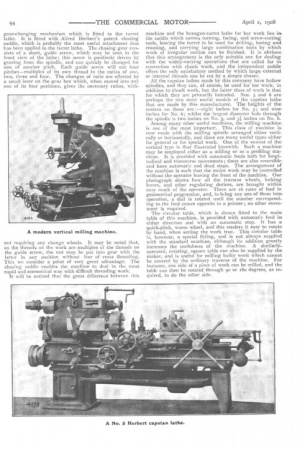

Alfred Herbert, Limited, of Coventry, the most famous of our machine tool manufacturers, has invented a patent, roller, " steady " tool, which, although of apparently simple construction, has effected an astonishing increase in the production of work from the bar. By its use, heavy cuts are possible, and the output of the machine is greatly increased. Three machines by this well-known, Coventry machine-tool maker are illustrated herewith. One of these is a standard, hexagon-turret lathe. This type of tool is built in three sizes, the smallest of which is capable of producing work up to itinch in diameter by 21 inches long, and the largest can deal with pieces up to ;V: inches in diameter by 42 inches long, direct from rolled bar. This model has a single-belt drive, and, by the manipulation of two levers, any one of 16 gear combinations can be brought into use; the feed of the tool may easily be altered, even

when the machine is w by the aid of the hand wheel which is seen immediately below the two gear-changing levers. The turret slide is of unusual length, and the turret is made to carry six different tools. A separate view of

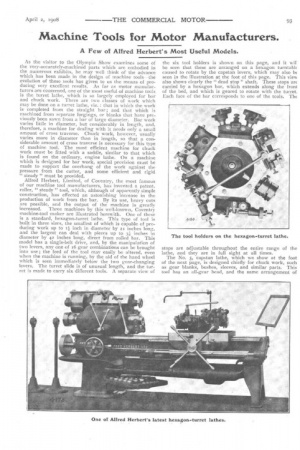

the six tool holders is shown on this page, and it wit be seen that these are arranged on a hexagon turntable caused to rotate by the capstan levers, which may also be seen in the illustration at the foot of this page. This view also shows clearly the "dead stop" shaft. These stops are carried by a hexagon bar, which extends along the fronl of the bed, and which is geared to rotate with the turret, Each face of the bar corresponds to one of the tools. The

stops are adjustable throughout the entire range of the lathe, and they are in full sight at all times. The No. 5, capstan lathe, which we show at the foot of the next page, is designed chiefly for chuck work, such as gear blanks, bushes, sleeves, and similar parts. This tool has an all-gear head, and the same arrangement of gear-changing mechanism which is fitted to the turret lathe. It is fitted with Alfred Herbert's patent chasing saddle, which is probably the most useful attachment that has been applied to the turret lathe. The chasing gear consists of a short, guide screw, which may be seen in the front view of the lathe; this screw is positively driven by gearing from the spindle, and can quickly be changed for one of another pitch. Each guide screw will cut four pitches—multiples of its own thread in the ratios of one, two, three and four. The changes of ratio are effected by a small lever on the gear box which, when moved into any one of its four positions, gives the necessary ratios, with out requiring any change wheels. It may be noted that, as the threads on the work are multiples of the threads on the guide screw, the nut may be put into gear with the latter in any position without fear of cross threading. This we consider a point of very great advantage. The chasing saddle enables the machine to deal in the most rapid and economical way with difficult threading work. It will be noticed that the great difference between this machine and the hexagon-turret lathe for bar work lies in, the saddle which carries turning, facing, and screw-cutting tools, leaving the turret to be used for drilling, boring and. reaming, and carrying large combination tools by which work of irregular outline can be finished. It is .obvious. that this arrangement is the only suitable one for dealing with the widely-varying operations that are called for in connection with chuck work, and the independent saddle offers the only satisfactory method by which large external or internal threads can be cut by a simple chaser.

All the capstan lathes made by this company have hollow spindles, and they can, of course, be used for bar work, in addition to chuck work, but the latter class of work is that for which they are primarily intended. Nos. 5 and 6 areperhaps the two most useful models of the capstan lathethat are made by this manufacturer. The heights of thecentres on these are :—eight inches for No. 5 ; and nineinches for No. 6; whilst the largest diameter hole through the spindle is two inches on No. 5, and 3a inches on No. 6.

Among many other useful machines, the milling machineis one of the most important. This class of machine isnow made with the milling spindle arranged either vertically or horizontally, and there are many useful types either for general or for special work. One of the newest of thevertical type is that illustrated herewith. Such a machinemay be employed either as a milling or as a profiling machine. It is provided with automatic feeds both for longitudinal and transverse movements; these are also reversible and have automatic and dead stops. The arrangement of the machine is such that the entire work may be controlled without the operator leaving the front of the machine. Our photograph shows how all the traverse wheels, locking levers, and other regulating devices, are brought within easy reach of the operator. There are 16 rates of feed in geometrical progression, and, to bring any one of these into. operation, a dial is rotated until the number corresponding to the feed comes opposite to a pointer ; no other movement is required. The circular table, which is shown fitted to the main table of this machine, is provided with automatic feed irv either direction and with an automatic stop. It has a quick-pitch, worm wheel, and this renders it easy to rotate by hand, when setting the work true. This circular table is, however, a special fitting, and is not always supplied with the standard machine, although its addition greatly increases the usefulness of the machine. A similarlyoperated, rotating, square table can also be supplied by the maker, and is useful for milling bulky work which cannot be covered by the ordinary traverse of the machine. For instance, one side of a piece of work can be milled, and thetable can then be rotated through 90 or 18o degrees, as required, to do the other side.