Lamps Alight.

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

Light your lamps at 7.2 in London, 7.50 in Edinblue. 7.12 in Newcastle, 7.16 in Liverpool, .7.10 in Birmingham, 7.12 in Bristol, and 7.57 in Dublin.

Modifying a Multiple-disc Clutch.

The sender of the following communication has been awarded the 10s. prize this week.

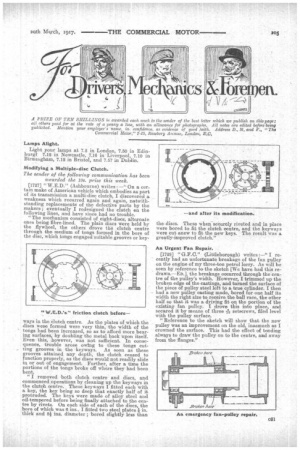

[1727] " W.E.D." (Ashbourne) writes : -a" On a certain make of American vehicle which embodies as part of its transmission a multi-disc clutch, I discovered a weakness which recurred again and again, notwithstanding replacements of the defective parts by the makers; eventually I redesigned the clutch on the following lines, and have since had no trouble. "The mechanism consisted of eight-discs, alternate ones being fibre-lined. The plain discs were held by the flywheel, the others drove the clutch centre through the medium of tongs formed in the bore of the disc, which tongs engaged suitable grooves or key ways in the clutch centre. As the plates of which the discs were formed were very thin, the width of the tongs had been increased, so as to afford more bearing surfaces, by doubling the metal back upon itself. Even this, however, was not sufficient. In consequence, trouble arose owing to these tongs cutting grooves in the -keyways. As soon as these grooves attained any depth, the clutch teased to function properly, as the discs would not readily slide na or out of engagement. Further, after a time the portions of the tongs broke off where they had been bent.

"I removed both clutch centre and discs, and commenced operations by cleaning up the keyways in the clutch centre. These keyways I fitted each with a key, the key being so deep that exactly half of it protruded. The keys were made of alloy steel and oil-tempered before being finally attached to the centre by rivets. On each side of each of the discs, the bore of which was 6 ins., I fitted two steel plates* in. thick and si ins. diameter ; bored slightly less than the discs. These when-securely riveted and in place were bored to fit the clutch centre, and the keyways were cut anew to fit the new keys. The result was a greatly-improved clutch."

An Urgent Pan Repair.

[1728] " G.F.C." (Littleborough) writes :—" I recently had an unfortunate breakage of the fan pulley on the engine of my three-ton petrol lorry. As will be seen by reference to the sketch [We have had this redrawn.—En.], the breakage occurred through the centre of the pulley's width. However, I trimmed up the broken edge of the castings, and turned the surface of the piece of pulley steel left to a true cylinder. I then had a new pulley. casting made, bored for one half its width the right size to receive the ball race, -the other half so that it was a driving fit on the portion of the existing fan pulley. I drove this into place, and secured it by means of three.11-6setscrews, filed level with the pulley surface.

"Reference to the sketch will show that the new pulley was an improvement on the old, inasmuch as I crowned the surface. This had the effect of tending always to draw the pulley on to the centre, and away from the flanges."