HINTS ON MAINTENANCE.

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Troubles.

CONTRIBUTIONS are invited for this page from fleet managers, drivers, garage foremen and mechanics, works staff and draughtsmen, and will be paid for on a generous scale. ' Every system, make, and type, of commercial motor vehicle will be dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle—practices which, whilst they may be quite normal, are peculiar to the particular vehicle and may not be generally known to those responsible for its running. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, headed "Roadside and Garage." Communications should be addressed to "The Editor, The Commercial Motor, 7-15, Rosebery Avenue, London, E.C. 1."

39.—Removing Leyland Fan Pulley.

A drift should never be employed to remove a fan pulley, as this often leads to damaging its flanges. In the case of the Leyland engine, two tapped holes will be found in the pulley, and a plate may be attached to these by means of bolts. The centre of the plate should be tapped and a long bolt screwed through its centre to bear on the end of the crankshaft.. By screwing in this bolt the pulley can be withdrawn.

40.—How to Cut Joints.

The uninitiated, when cutting out packing to use as joints between cylinders and crankcases in petrol engines or for the cylinder covers on steam' wagons, often attempt to mark out the material using the face of the cylinder as a pattern and marking through the holes and round the edge with a scriber. This method is not very accurate and it is extremely difficult to cut the material. The usual workshop way of doing the job is to place the material over the face to which it is to be fitted, passing the ball end of a hammer over the jointing and pressing it into the holes. This dents the jointing, enabling it to be held in position whilst.it is being cut by tapping it against the sharp edges of the casting with the ball end of the hammer; afterwards the holes can be cut in the same manner.

41.—Improving Old Zenith Carburetters.

• Many commercial vehicles are still fitted with the old-type Zenith carburetter, and occasionally these cause trouble owing to• difficult starting and inability of the engines ta run slowly until they become thoroughly heated. This is particularly noticeable on cold mornings.

These faults can be cured by soldering a piece of brass foil round the air inlet to the auxiliary jet and 054 drilling a small hole in this foil, so that the air is not altogether cut off. It will be Jound that if this be done the size of the compensator jet will probably have to be cut down, but even then the engine will usually run remarkably slowly, The-cause there is a practically constant vacuum at this point. The size of the hole is of some importance and must be regulated to suit the engine; it may be as small as .5 mm. If any difficulty is now experienced in starting, an ordinary pin can be inserted into the hole to cut off the small amount of air which normallypasses ' , through it, but, of course, the pin must not be left in the latter once the engine is started. The later patterns of Zenith carburetters have been greatly improved, and no difficulty is usually experienced in starting engines to which these instruments are fitted.

42.—Removing a Yorkshire Piston Rod. To remove the piston rod from the cross-head on a Yorkshire steam wagon is sometimes a matter of considerable difficulty, but if all methods of gentle persuasion fail it can be removed by uncoupling the connecting rod from the crank and lowering the piston to the bottom of the cylinder. Then if a stiff bar is held against the trunk of the cross-head and given a small blow with a heavy hammer the cross-head and rod will separate at the first blow, and neither of the parts will be in any way injured.

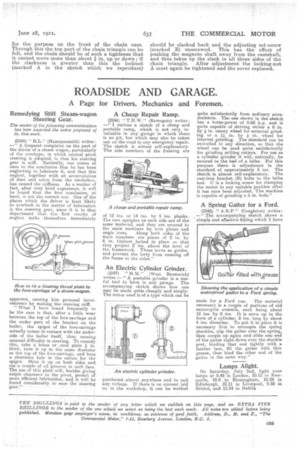

43.—Adjusting Napier Camshaft Chain. On the Napier lorry, the drive from the crankshaft to the cam and magneto shafts is taken by means of a silent type chain. This is consequently rather long, and a slight amount of wear on each rivet causes it to stretch considerably. This stretching is more noticeable in a new chain than in one which has been runnit', for some time, and after the first 10.000 miles it is advisable to ascertain whether the wear, is unduly great. This can be done through a door specially provided

for the purpose on the front of the chain case. Through this the top part of the chain triangle can be felt, and the chain should he of such a tightness that it cannot move more than about in. up or down ; if the slackness is greater than this the locknut (marked A in the sketch which we reproduce) should he slacked back and the adjusting set screw (marked B) unscrewed. This has the effect of pushing the magneto shaft away from the canishaft, and thus takes up the slack in all three sides of the chain triangle. After adjustment the locking-nut A must again be tightened and the cover replaced.