'Economical Transport of Heavy Loads is Only One of the

Page 20

Page 21

Page 22

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

Super Beaver's Attractions, Strenuous Tests Over Rough Surfaces• Failed to Show Weaknesses

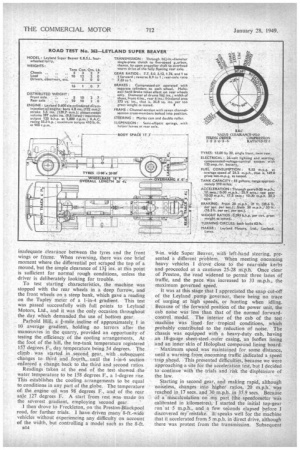

W, HEN taking over for test the Leyland Super .. Beaver, an exportmodel, I was immediately ,-irnpressed by its massive. proportions. It was shoff_with '13.00 by 20 tyres, the radiator filler was abae eye level, and the overall width at the rear wheels wasapproaching 8 FL 9 ins. As it was such a gigantic machine, designed for tough going, I tested it over a " battle •course," and it passed-ont".with full marks. The chassis frame side -member :section is 12 ins deep, 11 in thick and 3 ins wide on the flanges. These memhers' are.Suitably. reirifOrced With robust cross-members bolted into position'. The rear-axle casing—a cast centre section carrying the axle tubes, which are pressed into positkin—.Thouses a wOrrn •driVe of 9-in, centres, a unit built to Withstand the severest operating conditions.

Powerful air brake, with large-area facings, provide adequate retardation for the 16 tons gross weight of the machine. " Mounted directly _over .the king pins, the front air-pressure cylindersare fitted with easily :manipulated thumb-screws, which allow fine brake adjustment. The rear operating -cylinders are attached to the main axle casting, and actuate the shoes through levers and extended camshafts. A thumb-screw adjustment is also provided for the rear brakes.

Steering Unusually Light

Wiles cam-and-dOuble-roller steering gear, employed in conjunction with a 21-in, steering wheel, and geared to a ratio of 28.5 to 1, affords a lightness of control that would hardly be expected in such a large vehicle.

The power behind the machine is derived from the Leyland 0.600r.six-cylindered direct-injection oil engine which develops, With accessories, 125 b.h.p.at 1,800. r.p.m. Features of the engine include a-new fuel-pump governor-control arrangement, frozen-in Stellite-faced valve seats,:and.eopper-lead-indium-coated bearings of relatively large :projected area. Stellite-faced nickelsteelvalves are .,employed, their stems being chromium plated for 'longevity. In the Leyland. fuel-pqmp governor control, the butterfly in the. air-induction manifold iS .arranged to give a high velocityat sMall throttle opening, providing a' sensitive control of. the 10W-speed vacuum governor • for idling: A diaphragm: is connected to the end of the pump control -raok and, -topreLvent-hunting, a vacuum balancing valve is fitted to the end casing of the 1312

governor. The momentary interruption of the depression when the valve opens destroys the harmonic oscillations which promote hunting at idling or part load. A mechanical goVernor controls the high-speed cut-off.

Fuel from the C.A.V. injection pump is atomized in four-hole injectors of Leyland manufacture. The injectors, housed vertically in the twin interchangeable cylinder heads, spray directly into' the toroidal cavity formed in the piston crown. '

Adequate lubrication is provided by the *gallon sump, and the tropical radiator, which has a surface area of 6 sq. ft., ensures cool running. The 20-in.diameter four-bladed fan operates. in 'a full shroud, and a thermostatic control is fitted for rapid warmin.g up,from a cold start.

The single-dry-plate clutch of 16f-in. diameter has

an exceptionally thick facing, and 'adjustment for wear is made by a four stagearrangement. Gear changing is simplified by the constant mesh arrangement of the three upper; ratios, and with' the long selector lever, the action is light-and smooth. Helical gears are fitted to the third and fourth ratios to promote quietness in the intermediate r speeds. A system of positive lubrication is incorporated in the gearbox, so that the third and fourth gears and spigot mainshaft bearings receive a constant .supply of oil.

Both propellefshafts, supported by an intermediate bearing from the centre cross-member, have Hardy Spicer universal joints with needle-roller bearings.

Had the test machine been equipped with 11.00 by 20 tyre S the -overall width would have been under 8 ft., but in the circumstances I considered it wiser to use the main road as far as possible. The Super Beaver was first -driven to Parbold, a distance of 15 miles from Leyland, for its trials over an unmade road leading to some quarries. • The wide tracks of the Leyland did not permit it to run in the ruts formed by other traffic,. and -the two rear outer wheels took the entire load of the rear axle, the inner -.wheels .riding deaf of the grOund.The pace was restricted to prevent damage to• the Lyres, and it was not until a clearing was reached "

that speed could be increased. "

I drove over hillocks and mounds and-through-deep potholes; with the steering on full lock and straight ahead, but all these manceuvres failed • to . reveal inadequate clearance between the tyres and the front wings or frame. When reversing, there was one brief moment where the differential pot scraped the top of a mound, but the ample clearance of 13i ins, at this point is sufficient for normal rough conditions, unless the driver is deliberately looking for trouble.

To test starting' characteristics, the machine was stopped with the rear wheels in a deep furrow, and the front wheels on a steep bank, which gave a reading on the Tapley meter of a 1-in-4 gradient. This test was passed successfully with full points to Leyland Motors, Ltd., and it was the only occasion throughout the day which demanded the use of bottom gear:

Parbold Hill, a i-mile,incline of approximately_ 1 in 10 average gradient, holding no terrors after the manceuvres in the quarry, provided an opportunity of testing the efficiency of the cooling arrangements, At the foot of the hill, the top-tank temperature registered 157 degrees F., day temperature being 54 degrees. The climb , was started in second gear, with subsequent changes to third and fourth, until the 1-in-6 section enforced a. change back to the third and second ratios.

Reading's taken at the end of the test showed ,the water temperature to be 158 degrees F., a 1-degree rise. This establishes the cooling arrangements to be equal to conditions in any part of the globe. The temperature of the engine oil was 98 degrees F., and of the rear axle 127 degrees F. A start from rest was made on the severest gradient, employing second gear.

1 then drove to Freckleton, on the Preston-Blackpool road, for further trials. I have driven many 8-ft.-wide vehicles without experiencing any difficulty on account of the width, but controlling a model such as the 8-ft.

B14 9-in. wide Super Beaver, with left-hand steering, presented a different pXOblem. When meeting oncoming heavy vehicles I drove close to the near-side kerbs and proceeded at a cautious 25-28 m.p.h. Once clear of Preston, the road widened to permit three lanes of traffic, and the pace was increased to 33 m.p.h., the maximum governed speed.

It was at this stage that I appreciated the snap cut-off of the Leyland pump governor, there being no trace of surging at high speeds, or hunting when idling. Because of the forward position of the power unit the cab noise was less than that of the normal forwardcontrol model. The interior of the cab of the test machine was lined for tropical conditions, which probably contributed to the reduction of noise. The chassis was equipped with a heavy-duty cab, having an 18-gauge sheet-steel outer casing, , an Isoflex lining and an inner skin of HoIoplast compound lining board.

Maximum speed was rnaintained for some distance, until a warning from oncoming traffic indicated a speed trap ahead. This presented difficulties, because we were approaching a site for the acceleration test, but I decided to continue with the trials and risk the displeasure of the law.

Starting in second gear, and making rapid, although noiseless, changes into higher ratios, 20 m.p.h. was reached in 17 secs. and 30 m.p.h. in 35.9 secs. Because of a-miscalculation on my part (the' speedometer was calibrated in kilometres), I started the initial top-gear run at 5 m.p.h., and a few seconds elapsed before I discovered my" mistake. It speaks well for the machine that it accelerated from 5 m.p.h. in direct drive, although there was protest from the transmission. Subsequent

runs from 10 m.p.h. established that 20 m.p.h, could be reached in 17.5 secs, and 30 m.p.h. in 35.2 secs. .

Braking tests proved that the rate of retafdation was good for the class of vehicle. The severest trial in normal operation would be an emergency application after descending a long decline. As there was no slope in the area with a suitable flat stretch at the end, I reproduced these conditions by driving with the brakes applied for nearly two miles. This had the desired effect, and all the drums were smoking throughout the remainder of the braking trials. From 20 m.p.h. the vehicle was brought to rest in 21 ft., all wheels braking evenly. At 30 m.p.h. the off-side rear wheels tended to lock, the stopping distance recOrded being 53 ft.

The 12-mile retkiin journey to the works formed the route for the fuel-consumption trial. It was a reasonably level course, and with the exception of sealing

Pear Tree and two traffic-light halts,. no other occasion deinanded the use of intermediate gears. I tried to maintain a speed of 30 M.p.h., but because of the width cif the Beaver I was unableto ovei take a slower :moving lorry, and the speed was restricted to 24 imp h. for nearly two miles. •

There was little space to spare when passing a but on a comparatively narrow bridge by Leyland station, but otherwise the test was run without incident. Deducting stationary times, the route was covered al an average speed of 24.2 m.p.h., the fuel return .being 9.33 m.p.g., a highly satisfactory result.

The total and distributed weights were determined at the Earington workS, where it was found that the load was. correctly distributed betWeen the axles. In the territory to which this vehicle is being sent there is no law to condemn the l0-ton load of the rear axle.

The. Super Beaver can comfortably compete with Continental and transatlantic vehicles in pulling power, stability and strength. Its fuel consumption is probably better than that of its competitors, and the general ease of control is a notable feature. Although American models of this capacity might be fitted with power steering, this is not necessary for the Leyland, which has exceptionally light steering.'

Fitted with the low-ratio.final-drive unit, the Leyland really required, a trailer as a restraint, and for a solo machine I would prefer to employ the higher ratio of 6.5-to L