LEYLAND M.C.W. OLYMPIC IN PRODUCTION

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

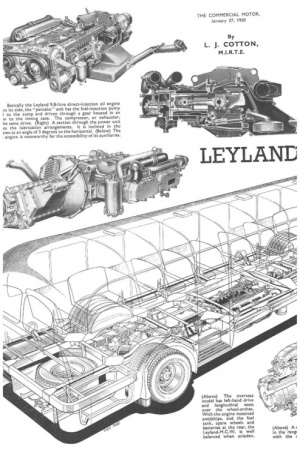

i-in.-diameter fan operating in a close-fitting cowl and eating at l times engine speed. Compressed-air Akes are fitted to the overseas vehicles, and a vacuum ;tern is employed on the home models, the compressor exhauster being mounted opposite the fuel-injection imp and sharing the same drive. Located at the front the cylinder block, the water pump is driven from the ankshaft by belts and pulleys, and is in triangulated lye with an adjuster pulley, having a manually nrated screw gear.

Apart from these alterations and a modification to the Jape of the sump, the power unit is almost identical ith the vertical engine. It has a monobloc iron crankise and cylinder block, with pre-finished shoulder • cated dry cylinder liners. Twin interchangeable flaticed heads are provided, and the combustion spaces re formed in the piston crowns. Operated by push-rods nd rocker levers, the valves are housed in the heads nd have chromium-plated stems to reduce wear. Oil

is delivered by a gear-type pump, which is driven by a helical gear on the rear of the camshaft. A full pressure supply is maintained, through a large-capacity full-flow filter, to the main, big-end and camshaft bearings. The lubricating system incorporates a normal wet-type sump. An oil-bath air cleaner is located near the engine on the underframe.

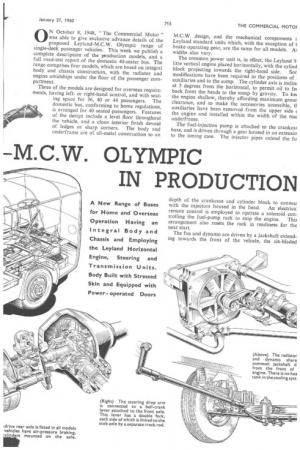

The engine, clutch and gearbox are of unit construction, flexibly mounted at the rear by links fitted with Harrisflex bushes, and supported at the front on a rubber-bonded bush. This constrains the unit to oscillate on an axis between its centre of gravity and the front of the propeller shaft, thus reducing vibrations transmitted to the frame. This unit is supplied by Leyland complete with mountings and crossbearers of a length to suit the underf came.

Helical gearing is used for the four-speed gearbox, the three upper ratios being in constant mesh and engaged through synchromesh arrangements. Located centrally in the driving compartment, the selector lever operates through light tubes and universal joints to the gearbox.

A single propeller shaft with Hardy Spicer joints and needle-roller bearings conveys the drive to the bevelgeared final-drive unit of the fully floating rear axle. This has a cast-steel centre with tubular ends bolted in position. The rear-spring dumb irons are flanged and shaped to conform to the underframe, and crossmembers are suitably positioned to provide support. Driving and braking torque reaction is absorbed in the springs.

The rear brake operating cylinders of the overseas

models are secured to flanges on top of the axle and operate the shoes through rods and levers; they have scissors-pattern adjusters. Home models, equipped with the Clayton Dewandre triple-servo braking system, have the conventional linkage from the main servo motor, which takes effect on the shoes through rods and a transverse cross-tube. R.P. automatic adjusters are provided for compensating facing wear. The two compressed-air reservoirs are carried under the floor of the cab, supplying power for the brakes and door operation. Westinghouse air-pressure equipment is specified for the export vehicles. In the case of the home vehicle, the vacuum reservoir is mounted amidships on the near side of the underframe.

• Bolted to the front of the main longitudinal frame member, the steering box has its drop arm connected to a bell-crank lever attached to the axle, which in turn is linked by a divided track rod to the stub axles. This lay-out is used because of minor troubles experienced with the conventional system when braking and corner ing. The modified arrangement provides accuracy in steering under all load conditions, the effort being lighter and constant.

Placed immediately in front of the engine to avoid extensive plumbing, the radiator tube stack is squat and deep, and devoid of a header tank. Its filler tube joins the bottom water pipe at the base of the radiator. Obviously the power absorbed by the fan is greater than by conventional cooling systems, but an induced draught is essential through the radiator because it is shielded.

In the development of the underframe of the body, there are two main longitudinal channel-section members extending the full length of the vehicle. The lefthand member is in one piece, but the opposite side is in three parts to accept the full width of the engine and its bearers. Nine channel-section cross-members with outriggers are spaced along the side members to give the maximum rigidity, and are riveted in position, with additional strengthening by sturdy gusset plates. All these main members are of 6-in. by 24-in. by 3/16-in. section.

Sills of a lighter section are attached to the extremities of the outriggers, and are secured in conjunction with the vertical members of the body, which comprise 3 /32-in. extrusions. Top-hat-section members tie the verticals in position at waist height, whilst a heavy moulded bumper rail is bolted to the ends of the outriggers. Because the design is planned with stressed-skin cc struction, the outer panels, from the bumper rail waist line, are of 3 /32-in. gauge, and form part of t load-carrying structure. A " double-length " panel fitted to each side of the body near the engir Additional support is provided at the wheel-arches 1 diagonal channel-section bracings, which are riveted the inner side of the outer skin.

The outer side, end and roof panels are secured t snap-headed rivets, whilst the interior panels, includit the roof lining, are joined by blind rivets. A relative light skirting in the form of panels or removab .valences is fitted, the material being 18-gauge light allo Removable valences are fitted on both sides of the boc near the engine and over the battery crate and spar wheel carrier at the rear. Stainless-steel wheel-arch( are employed. On the prototype home model offered ft test, the wheel-arch formed a slight obstruction t passengers seated over the front axle. Subsequent mode are being equipped with a modified suspension systei which enables the wheelarch obtrusion to be reduced by 2 ins.

All seats face forward in the home body, but the overseas vehicles have longitudinal seats over the wheel-arches. Comfortable " city-service " seats are installed, and are constructed on tubular steel frames with chromium-plated open-top grab rails. The cushions and squabs are upholstered with leather on sponge-rubber fillings, and the rear faces of the seat backs are finished with leathercloth. A minimum distance of 2 ft. 31 ins, is provided between the seats facing forward. The fiat floor adds to the convenience and safety of standing passengers and is covered with a durable non-slip material. Extractor ventilators, fitted in the roof and front panels, provide an even distribution of air throughout the saloon.

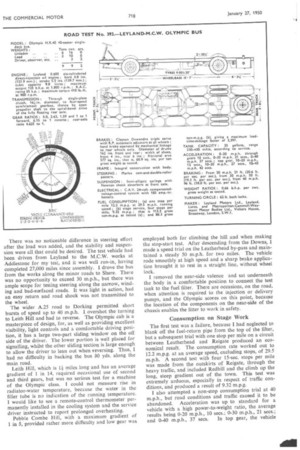

The Olympic range is available in four wheelbases of 15 ft. 1 in., 17 ft. 6 ins. and 20 ft. 4 ins, for the three overseas models for 36, 40 and 44 seated passengers respectively, and 15 ft. 7 ins, for the 40-seater home vehicle. It was the home model which was provided for my test, and I took the opportunity of riding and driving the bus before the load was added. The suspension, when unladen, was excellent, a quality which may be attributed to the balanced layout of the mechanical components and the siting of the batteries, spare wheel and fuel tank at the extreme rear of the body.

There was no noticeable difference in steering effort after the load was added, and the stability and suspension were all that could be desired. The test vehicle had been driven from Leyland to the M.C.W. works at Addlestone for my test, and it was well run-in, having completed 27,000 miles since assembly. I drove the bus from the works along the minor roads to Shere. There was no opportunity to exceed 30 m.p.h., but there was ample scope for testing steering along the narrow, winding and bad-surfaced roads. It was light in action, had an easy return and road shock was not transmitted to the wheel.

The wider A.25 road to Dorking permitted short bursts of speed up to 40 m.p.h. I overshot the turning to Leith Hill and had to reverse. The Olympic cab is a masterpiece of design, for, as well as providing excellent visibility, light controls and a comfortable driving position, it has a large two-part sliding window on the off side of the driver. The lower portion is well placed for signalling, whilst the other sliding section is large enough to allow the driver to lean out when reversing. Thus, I had no difficulty in backing the bus 30 yds. along the main road.

Leith Hill, which is 11 miles long and has an average gradient of 1 in 14, required occasional use of second and third gears, but was no serious test for a machine of the Olympic class. I could not measure rise in radiator-water temperature, because the water in the filler tube is no indication of the running temperature. I would like to see a remote-control thermometer permanently installed in the cooling system and the service driver instructed to report prolonged overheating.

Pebble Combe Hill, with a maximum gradient of 1 in 5, provided rather more difficulty and low gear was

employed both for climbing the hill and when making the stop-start test. After descending from the Downs, I made a speed trial on the Leatherhead by-pass and maintained a steady 50 m.p.h. for two miles. The vehicle rode smoothly at high speed and a sharp brake application brought it to rest in a straight line, without wheel lock.

I removed the near-side valence and sat underneath the body in a comfortable position to connect the test tank to the fuel filter. There are occasions, on the road, when attention is required to the injection or delivery pumps, and the Olympic scores on this point, because the location of the components on the near-side of the chassis enables the fitter to work in safety.

Consumption on Stage Work The first test was a failure, because I had neglected to blank off the fuel-return pipe from the top of the filter, but a subsequent trial with one stop per mile on a circuit between Leatherhead and Reigate produced an economical result. The consumption rate worked out to 12.2 m.p.g. at an average speed, excluding stops, of 29.5 m.p.h. A second test with four 15-sec. stops per mile was made from the outskirts of Reigate, through the heavy traffic, and included Redhill and the climb up the long, steep gradient out of the town. This test was extremely arduous, especially in respect of traffic conditions, and produced a result of 9.32 m.p.g.

I also attempted a non-stop consumption trial at 40 m.p.h., but road conditions and traffic caused it to be abandoned. Acceleration was up to standard for a vehicle with a high power-to-weight ratio, the average results being 0-20 m.p.h., 10 secs.; 0-30 m.p.h., 21 secs.; and 0-40 m.p.h., 37 secs. In top gear, the vehicle accelerated from 10 m.p.h. to 20 m.p.h, in 12 secs., from 10-30 m.p.h. in 27 secs., and from 10-40 m.p.h. .in 42 secs.

The concrete road surface was dry and in good condition for braking tests. When the brakes were applied at 40 m.p.h., the bus came to rest in 96 ft., and runs at 30 m.p.h. and 20 m.p.h. produced stopping distances of 50 ft. and 21 ft. respectively, This -is an adequate retardation for passenger safety.

The Olympic bus is above the normal for smooth riding and passenger comfort under all conditions of load. The absence of pitching when light, and rolling when laden, contributes largely to comfort, and although the vehicle had covered 27,000 miles, the body was free-. from squeaks and rattles. No attempt has been made to use expensive panelling in the saloon, but it has a light, clean finish, and the upholstery and trimming are serviceable.

The maker's claim for reduced noise and freedom from fumes is well justified and the engine suspension eliminates vibration in the body. I liked driving the Olympic and found that the glass panels in the lower parts of the entry doors could be helpful when steering into the kerbside.