Radiant Heat—A New Technique in Paint-drying

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A MEANS for the quick-drying of 1k newly painted surfaces of vehicle bodies was last week demonstrated at the Paints Division of Imperial Chemi cal Inchistries, at Slough. Operators will readily appreciate the value of the apparatus, for vehicles have often to be out of use for lengthy periods when normal air-drying methods are relied upon.

It is not suggested that a complete body should be treated with the equipment as the cost would be prohibitive. The process applies more particularly to the treatment of comparatively small areas, such as are represented by doors, panels, etc.

The process relies upon the application of radiant heat. Two types of plant are used for this purpose. In one the heat is obtained from electric lamps, which are manufactured by the General Electric Co., and, in the other, dullemitter heaters made by the Sun Electric Co. are employed.

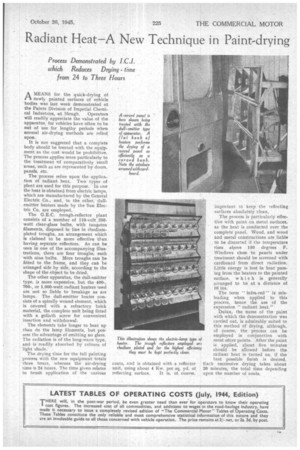

The G.E.C. trough-reflector plant consists of a number of 110-volt 250watt clear-glass bulbs, with tungsten filaments, disposed in line in rhodiumplated troughs, an arrangement which is claimed to be more effective ti-an having separate reflectors. As can be seen in one of the accompanying illustrations, there are four troughs, each with nine bulbs. More troughs can be fitted to the frame, and they can be arranged side by side, according to the shape of the object to be dried.

The other apparatus, the dull-emitter type, is more expensive, but the 400-, 700-, or 1,000-watt radiant beaters used are not so liable to breakage as aie lamps. The dull-emitter heater consists of a spirally wound element, which is covered with a refractory brick material, the complete unit being fitted with a goliath screw for convenient insertion and withdrawal.

The elements take longer to heat up than do the lamp filaments, but possess the advantage of emitting no glare. The radiation is of the long-wave type, and is readily absorbed by colours of light shade.

The drying time for the full painting process with the new equipment totals three hours, whereas the air-drying time is 24 hours. The time given relates to brush application of the various coats, and is obtained with a reflector unit, using about 4 Kw. per sq. yd. of reflecting surface. It is, of course, impottant to keep the reflecting surfaces absolutely clean.

The process is particularly effective with paint on metal surfaces, as the heat is conducted over the complete panel. Wood, and wood and metal constructions are liable to be distorted if the temperature rises above 180 degrees F. Windows close to panels under treatment should be screened with cardboard from direct radiation. Little energy is lost in heat passing from the heaters to the painted surface, w hich is generally arranged to be at a distance of 10 ins.

The term '' infra-red'" is misleading when applied to this process, hence the use of the expression " radiant heat."

Dulux, the name of the paint with which the demonstration was carried out, is admirably suited to this method of drying, although, of course, the process can be employed in conjunction with most other paints. After the paint is applied, about five minutes should be allowed before the radiant heat is turned on, if the best possible finish is desired. Each successive drying takes about 20 minutes, the total time depending upon the number of coats.