A LTHOUGH the use of automatic transmissions on medium-sized and large

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

cars is becoming more common in this country (in the U.S. cars with manual gearboxes are the exception rather than the rule), so far there has been very little application here of such transmissions to goods vehicles. None, so far as British production models are concerned. The reasons for this are not difficult to find. Automatic gearboxes cost more than conventional units and they are usually more difficult to apply to commercial vehicles because it is not easy to adjust the speeds of the ratio changes to Suit the wide variation between laden and unladen gross vehicle weights.

This is certainly the case with torque-converter type transmission's, which generally require a relatively high powei-weight ratio, but the problem has to a large extent been overcome with the Hobbs 'Mecha-Matic gearbox. The unit fitted on the Thames 15-cwt. van which was the subject of this road test gaVe a performance in all conditions comparable to that obtainable with a manual box. The Hobbs Mecha-Matic gearbox has existed for a number of years. It was described in T he' COrnmercial Motor of August 29, 1958, prior to its exhibition at the Commercial Motor Show that year, and a road-test report of an L.C.C. ambulance fitted with the unit was included in our issue of June. 12, 1959. A range of designs has been 'fully developed, suitable for use in conjunction with engines with maximum torques of from 70 to 900 lb.-ft., but at present the only units being produced are those suitable for car and light commercial vehicles with engines of 1to 3-litre capacity. The unit .fitted to the van tested was the Type 1523 in the form suitable for a maximumtorque input of 112 lb.-ft.

All the versions follow the same basic design. The transmission is wholly mechanical in . operation and the system comprises three separate units—a clutch unit at the front end, a brake unit in the centre and a gear train at the rear—and there are two separate hydraulic circuits.

c24

Working from the back of the 1523 box, the gear tra is a compound planetary unit which provides four forwa ratios and one reverse. Elements of the gear train are he stationary by disc brakes in the central brake unit provide the intermediate ratios and reverse, and when secondary clutch in the front clutch unit is engaged the ge train is locked and rotates as a unit to provide direct drit The clutch and disc brakes, which are themselves simil to plate clutches, are actuated by hydraulic pressure appli through diaphragms to the pressure plates.

The clutch unit is bolted to the engine flywheel ai houses a main clutch as well as the secondary clut already referred to. The main clutch is used for t take-up of drive in first gear and is engaged for all forwa ratios. The secondary clutch is used in conjunction vvi the main clutch to provide direct drive, in which posig the three disc brakes are disengaged. It is also used for t take-up of drive in reverse gear, which is obtained wh the secondary clutch and the first gear brake are actuat together.

One hydraulic circuit includes an oil pump (driven frr the forward clutch housing), which supplies the operating oil pressure for the clutch and brake engagement. Delivery and pressure of the oil are controlled by valves housed with the pump in a hydraulic unit. Delivery of the oil under pressure to particular clutches and brakes is determined by a governor, valve in the second hydraulic circuit. Although there are two distinct operating circuits, the governor valve is housed, together with the front pump and other valves, in a self-contained hydraulic unit. This valve is controlled by oil pressure supplied by a pump driven by the gearbox output shaft. As a result, the pressure varies with the vehicle's speed. Movement of the governor valve is also :ontrolled by the position of the accelerator pedal, so that he pattern of automatic changing is determined by a :ombination of road speed and throttle opening.

An important feature of the Mecha-Matic transmission s that the governor valve can be overridden by a manual ;elector. Thus, upward—and, to a certain extent, downward—changes can be made manually. A lower gear annot be engaged, however, if the road speed is too high or that gear. The selector, which, in the case of the [lames van, was mounted in the same position as the tormal steering column gear-change lever, has positions 'or reverse, neutral, first, second and third ratios, and Lutomatie.

Other advantages of the design are that the engine can )e started by towing the vehicle at about 3 m.p.h. with ' automatic " selected. There is no "slip " in the transnission. as with fluid couplings, and there is no " creep " vhen idling correctly with a gear or automatic selected as the clutches are disengaged. There is engine braking in all gears and, as a certain amount of lubrication for the unit is provided by the rear oil pump, the vehicle can be towed in the event of breakdown without the need to disconnect the propeller shaft.

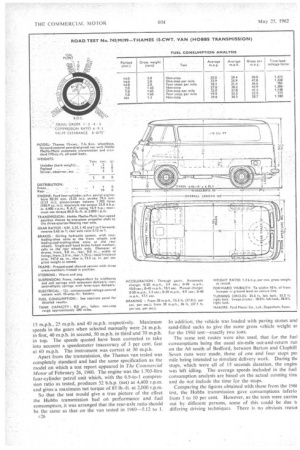

On the van tested it was found that with a light throttle depression changes from first to second ratio were made at 5 m.p.h.: changes from second to third at 14 m.p.h., and from third to top at 21 m.p.h. With full throttle the respective speeds were 10 m.p.h., 20 m.p.h. and 30 m.p.h., whilst downward movement of the accelerator pedal beyond the full-throttle position opened the " kick-down valve to increase the road speeds for the changes to 15 m.p.h., 25 m.p.h. and 40 m.p.h. respectively. Maximum speeds in the gears when selected manually were 24 m.p.h. in first, 40 m.p.h. in second, 50 m.p.h. in third'and 70 m.p.h. in top. The speeds quoted have been corrected to take into account a speedometer inaccuracy of 3 per cent. fast at 60 m.p.h. The instrument was correct at 30 m.p.h.

Apart from the transmission, the Thames van tested was completely standard and had the same specification as the model on which a test report appeared in The Commercial Motor of February 26, 1960, The engine was the 1.703-litre four-cylinder petrol unit which, with the 6.9-to-1 compression ratio as tested, produces 52 b.h.p. (net) at 4,400 r.p.m. and gives a maximum net torque of 85 lb.-ft. at 2,000 r.p.m.

So that the test would give a true picture of the effect the Hobbs transmission had on performance and fuel consumption, it was arranged that the rear-axle ratio should be the same as that on the van tested in 1960-5.12 to I.

c26 in addition, the vehicle was loaded with paving stones and sand-filled sacks to give the same gross vehicle weight as for the 1960 test-exactly two tons.

The same test routes were also used, that for the fuel consumptions being the usual six-mile out-and-return run on the A6 south of Bedford, between Barton and Clophill Seven runs were made, those of one and four stops pei mile being intended to simulate delivery work. During du stops, which were all of 15 seconds duration, the engin( was left idling. The average speeds included in the fuelconsumption analysis are based on the actual running firm and do not include the time for the stops.

Comparing the figures obtained with those from the 196( test, the Hobbs transmission gave consumptions inferio from 3 to 10 per cent. However, as the tests were carrie( out by different persons, some of this could be due t( differing driving techniques. There is no obvious reasoi why the non-stop consumptions should be poorer with the automatic box. The indication is that factors other than the gearbox (such as engine tuning) were partly to blame. It is also likely that top gear was used for almost the whole of these runs on the 1960 test, whereas on this test the intermediate gears came into operation on the turn at Clophill. Taking into account all the factors, the fitting of the Hobbs box appears to have only a marginal effect on fuel consumption.

The results obtained on the hill-performance tests were interesting. Bison Hill, which is 0.75 mile long and has an average gradient of 1 in 10.5, with a maximum of 1 in 6.5, was used for these tests. Two maximum-power runs were made up the hill, one with automatic changing and one with the speed of the changes controlled manually. The " kick-down " accelerator pedal position was used for the ascent in "automatic," which took 2 minutes 28.2 seconds. Second gear was the lowest in use (for 20 seconds) and the -Teed dropped to 12 m.p.h. on the steepest section.

A much faster run was made when manual gear changes were made. Total time for the ascent in this case was minutes 7.7 seconds, second gear was the lowest used (for I6 seconds) and the minimum speed was 18 m.p.h. klthough the performance with automatic changes was not LS good as that obtained with the van tested in 1960 (the ime for the ascent then was 2 minutes 12 seconds), that 'or the run when manual changes were made was better. Phis was mainly due to the instantaneous ratio changes vhich could be made. On a third run up the hill the van vas stopped on the steepest section and was restarted easily without judder. When facing down the hill on the same section faultless restarts were made in reverse.

Because the gross weights and the braking systems on the current van and on the model tested in 1960 were the same, there would have been little point in carrying out brake tests. The figures included in the results panel are, therefore, those obtained in 1960.

Direct-drive acceleration figures could not, of course, be taken, but runs were made first with " automatic " selected and then using the manual selector. Runs were made in opposite directions on a level stretch of road to obtain the mean times quoted, which are excellent for a van of this size. The times show a slight improvement on those obtained in 1960.

Acceleration Figures It will be seen that there was very little difference between the times for acceleration when automatic changes were made and those when upward changes were .made manually. Automatic proved slightly quicker up to 20 m.p.h. and virtually identical times were obtained up to 30 m.p.h. Manual selection gave the better. times up to 40 m.p.h. These results actually contradicted first impressions of driving the van using the full automatic transmission. When I first took over the vehicle its performance seemed quite sluggish, but after I had beeome accustomed to driving it I realized that the feeling was due mainly to the smoothness of the transmission and, to a certain extent, to the accelerator pedal having an unusually heavy feel—the pedal had to be pressed particularly hard to get the " kick-down " position. These two points gave the impression that the accelerator had to be depressed more than normally for particular road speeds.

Another point was that the accelerator pedal had to be used to a certain extent as a gear-change pedal. By this I mean that when fast acceleration was required to keep up with traffic, extra depression could be given to bring about a downward change. All these impressions were obtained when the van was fully laden and the only criticism I have is that I would have preferred the changes from first to second and from second to third ratios to have been at a higher road speed for part-throttle positions.

However, the automatic transmission made driving the Thames 15 cwt. a most pleasant experience, particularly so in London's traffic. I am now convinced that, at the risk of developing wasted left-leg muscles and a corn-free left hand, I would dispense with the clutch pedal and gearchange lever and go for an automatic gearbox. There is the proviso, though, that it would have to be a well-designed transmission—as good as I found the Mecha-Matic.