THREE IMPORTANT IN

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

EW FODEN PRODUCTS

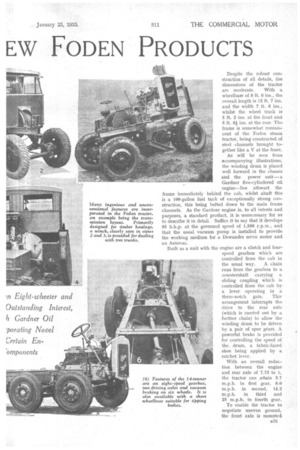

0 NLY a cursory glance at the latest products of Fodens, Ltd., Sandbach, Cheshire, is required for one to realize that they are typically British in design and construction, embodying as they do sound engineering principles and a characteristic robustness which should be reassuring to prospective purchasers. Whilst it is impossible to state that the layout of any of the vehicles is flagrantly unorthodox, there is a marked originality about the range which brings to one's notice the natural tendency of the general manager of the company— Mr. R. Wood Whittle—to "plough a lonely furrow."

This proclivity is particularly noticeable in the ingenious design of a timber-haulage tractor which has been developed for the special work involved in cutting down trees and hauling the trunks to a mill. The suspension of the front axles of the eight-wheeled 14-ton chassis also bears the stamp of originality, whilst the layout of a 5-ton model, although, naturally, planned on orthodox lines, typifies Foden principles for thoroughness in detail work.

We will deal first with the new tractor, because this machine. has been built to suit the requirements of a special class of work and, accordingly, the design is by no means conventional. Before going into details of construction, it should be stated that the tractor has been built to operate on rough, broken and soft ground, as well as on made roads, on which it has a capacity for pulling 12 tons at speeds up to the legal limit for a vehicle of this

Vim.

A point of particular interest is the inclusion of a winding gear with a drum containing 100 yds. of fin.diameter flexible steel rope, the vehicle being equipped with two anchors, one under the centre of the tractor and the other on the rear end of the frame. These enable complete trees to be hauled without moving the tractor. . A roller-type fairlead is attached to the frame at the front and the rear.

B32 Despite the robust construction of all details, the dimensions of the tractor are moderate. With a wheelbase of 8 ft. 6 ins., the overall length is 12 ft. 7 ins. and the width 7 ft. 6 ins., whilst the wheel track is 5 ft. 2 ins, at the front and 5 ft. 81 ins, at the rear. The frame is somewhat reminiscent of the Foden steam tractor, being constructed of steel channels brought together like a V at the front.

As will be seen from accompanying illustrations, the winding drum is placed well forward in the chassis and the power unit—a Gardner five-cylindered oil engine—lies athwart the frame immediately behind the cab, whilst abaft this is a 100-gallon fuel tank of exceptionally strong construction, this being bolted down to the main frame channels. As the Gardner engine is, to all intents and purposes, a standard product, it is unnecessary for us to describe it in detail. Suffice it to say that it develops 85 b.h.p. at the governed speed of 1,550 r.p.m., and that the usual vacuum pump is installed to provide the working medium for a Dewandre servo motor and an Autovac.

Built as a unit with the engine are a clutch and fourspeed gearbox which are controlled from the cab in the usual way. A chain runs from the gearbox to a countershaft carrying a sliding coupling which is controlled from the cab by a lever operating in a three-notch gate. This arrangement interrupts the drive to the rear axle (which is carried out by a further chain) to allow the winding drum to be driven. by a pair of spur gearS. A powerful brake is provided for controlling the speed of the drum, a fabric-faced shoe being applied by a ratchet lever.

With an overall reduction between the engine and rear axle of 7.73 to I, the tractor can _attain 3.7 m.p.h. in first gear, 8.6 m.p.h. in second, 14.2 m.p.h. in third and 25 m.p.h. in fourth gear.

To enable the tractor to negotiate uneven ground, the front axle is mounted on a trunnion at the centre of the chassis, a single inverted semi-elliptic spring being utilized to carry the • axle beam. A pair of radius arms is, of course, provided to constrain the fore-and-aft movement of the axle.

The steering is somewhat unorthodox, being planned to suit the special requirements of the vehicle. A ver tical column operates, through a worm-and-nut mechanism, a bell-crank lever slung from the underside of the frame. From this lever a drag-link communicates with the near-side wheel-pivot, and the usual track rod connects the two steering arms.

A solid rear axle, running in a pair of substantial plain bearings built as a part of the spring pads, is employed. Both hand and foot brakes operate only on the rear wheels, the pedal applying internalexpanding shoes in drums housed within the inner pair of the twin wheels, whilst the hand wheel operates a fabric-lined band which contracts on a drum built as a unit with the axle.

The axle itself is suspended on semi-elliptic springs

which are shackled at the front and rear, radius arms controlling the movement in order to maintain the correct chain tension. The list price of this model, with Trakgrip 40-in. by 8-in. tyres (twins at the rear), a spare wheel and tyre and a mechanically operated tyre pump driven from the gearbox, is £1,465. Furthermore, a 12-volt lighting and starting set, four wheel-spuds and a Foden patent trailer brake are also included in the specification.

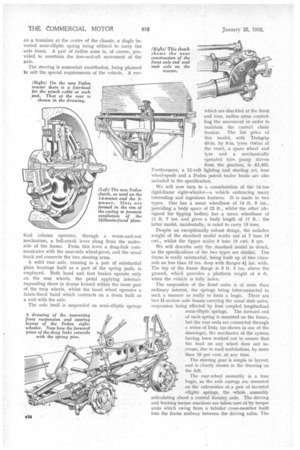

We will now turn to a consideration of the 14-ton rigid-frame eight-wheeler--a vehicle embracing many interesting and ingenious features. It is made in two types. One has a mean wheelbase of 14 ft. 8 ins., providing a body space of 22 ft., whilst the other (designed for tipping bodies) has a mean wheelbase of 11 ft. 7 ins, and gives a body length of 17 ft. ; the latter model, incidentally, is rated to carry 13 tons.

Despite an exceptionally robust design, the unladen weight of the standard model works out at 7 tons 19 cwt., whilst the tipper scales 8 tons 19 cwt. 3 qrs.

We will describe only the standard model in detail, as the specifications of the two types are similar. The frame is really substantial, being built up of two channels no less than 12 ins, deep with flanges 4i ins. wide. The top of the frame flange is 3 ft. 3 ins, above the ground, which provides a platform height of 4 ft. when the vehicle is fully laden.

The suspension of the front axles is of more than ordinary interest, the springs being interconnected in such a manner as really to form a bogie. There are two H-section axle beams carrying the usual stub axles, suspension being effected by four coupled longitudinal semi-elliptic springs. The forward end of each spring is mounted on the frame, but the rear ends are connected through a series of links (as shown in one of the drawings), the mechanics of the system having been worked out to ensure that the load on any wheel does not increase, due to road undulations, by more than 10 per cent, at any time.

The steering gear is simple in layout, and is clearly shown in the drawing on the left.

The rear-wheel assembly is a true bogie, as the axle casings are mounted on the extremities of a pair of inverted elliptic springs, the -whole assembly articulating about a central dummy axle. The driving and braking torque reactions are taken care of by torque arms which swing from a tubular cross-member built into the frame midway between the driving axles. The

last-named components have a worm and worm-wheel drive to fully floating half shafts. Both axles are used for the transmission of power, a short propeller shaft coupling the two worms.

A Gardner 6 L.W. power-unit is employed; it delivers 97 b.h.p. at 1,550 r.p.m. A single-plate clutch of Foden design (described later) transmits the drive to a dual type of gearbox providing eight forward and two reverse speeds. The main gearbox is operated in the ordinary manner, an auxiliary gear being brought into service by a secondary lever. To give an idea of the wide range of gearing which the arrangement permits, it might be added that, in the lowest gear with the auxiliary box in operation, the speed of the vehicle, at the governed engine speed of 1,550 r.p.m., is 2.2 m.p.h., whilst in "top" (without the auxiliary box) the vehicle speed is 36.9 m.p.h.

As might be expected in a vehicle of this character, a comprehensive braking system is employed. To give a light pedal pressure, a Dewandre vacuum system, employing three cylinders, is used. The pedal operates the master Dewandre cylinder, which is mounted just in front of the leading rear axle, a direct pull being exerted on a cross-shaft from which swinging levers connect with shoes in the drums on the bogie wheels.

The two auxiliary Dewandre cylinders are attached to the wheel pivots of only the leading axle.

The hand or parking brake is applied by a lever, through a ratchet, so that several strokes can be made in order fully to apply the shoes within the drums.

With an exceptionally full equip ment, including 40-in, by 8-in. straight-sided high-pressure tyres all round, with twin tyres at the rear, and a complete spare wheel, mounted on a carrier, the price works out at £1,943 for the chassis, the cab costing £50 extra and a hinged-sided lorry body a further £100.

As we have already indicated, the new 5-ton chassis follows much upon accepted Foden practice, the usual straight frame with adequate cross-bracing being em ployed, together with semi-elliptic springs all round, four-wheel brakes and a four-speed gearbox. The power-Unit is a Gardner 03 b.h.p. four-cylindered engine.

One of the Foden new-type clutches transmits the power by -means of a short clutch shaft to a separately mounted gearbox, the indirect ratios of which are 1.736, 3.037 and 6.775 to 1 ; the reverse gear ratio is the same as that of the first forward speed. A largediameter tubular propeller shaft connects with the overhead worm of the 6.25-to-1 rear axle.

This model is produced in two types, the wheelbase of the standard product being 12 ft., whilst in a special edition this dimension works out. at IS ft. 6 ins. ; the available body spaces are 14 ft. and 15 ft. respectively.

In each case the track measures approximately 5 ft. 7 ins., whilst the overall width of the chassis is 6 ft. 9 ins. The height of the top of the frame is 2 ft. S ins., making the laden height of a flat platform lorry 3 ft. 6 ins. With the usual Foden full equipment and 34-in. by 7-in. tyres (twins at the rear) the chassis price is £1,065—a figure which includes a spare rim and tyre mounted on a carrier. The cab costs an extra £50 and the hinged-sided lorry body a further £50.

Finally, two components are worthy of mention, one being a clutch and the other an hydraulic pump for use with tipping gears. The clutch is of the singleplate variety with the fabric riveted to the free member. The back and pressure plates are separate from the flywheel, being attached thereto by means of a six-stud fixing. As the springs are fitted between the flywheel and the pressure plate, the back plate is a fixture.

The sketch of the oil pump for hydraulic tipping gears is almost self-explanatory. From the usual gearbox power take-off, a shaft, terminating in a cam, is rotated in the crankcase of the pump, the four cylinders of which are arranged in radial fashion.

It will be noticed that there are two pipe unions in the pump body, the larger one being for the in-going oil and the smaller one for the out-going fluid under pressure. An important feature of the design is the fact that there are no running joints under pressure— a point of importance in a system where high fluid pressures are common. At 600 r.p.m.—the engine idling speed—the pump will deliver about six gallons of oil per hour at pressures up to 2,000 lb. per sq. in.