A Substitute for Air.

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

Government Recognition of the Value of Pneumatic-Tire Fillings.

One of the maintenance incidents encountered by the user of the light van and parcelcar is that of punctured tires, and the delay which is the natural result of such a misfortune. This is emphasized in the case of the three-wheeled type of p.axcelear, a type which has achieved very considerable success, as it is common knowledge that the accessibility of such models' rear wheels is not one of their strong points. The possibility of such trouble, moreover frequently acts as a deterrent when the horse owner is seriously considering the advisability of transferring his interests to the mechanically-propelled vehicle. In these days, when the reliability of the motor has arrived at such perfection, a punctuality is expected from the commercial motor far in excess of what is actually obtained by rail transport. This applies both with respect to goods delivery and also in the case of public-service vehicles. It is common knowledge that there are on the market at present few light vans designed to be suitable for running on solid tires. In the case of certain classes of goods the use of solids would be prohibitive, on account of the probable resultant damage owing to vibration. There have been several attempts to obviate this particular failing of the pneumatic tire, and these have assumed various forms. The more usual form taken by these is that of an elastic filling inserted in a molten state, but solidifying at ordinary temperatures, Unfortunately, in the majority of cases the remedy has proved to be worse than the disease. We have seen examples of tires so treated which have become, during a night, any shape but that which one normally expects to find, this being due to the fact that in some cases the filling was inserted into the inner tube in the ordinary way and at an insufficient pressure. As a consequence of such proceeding a considerable amount of chafing occurs in use which generates heat, with the result that at the end of a long run the substance has, to a certain extent, returned to the fluid state in which it was inserted.

It can be readily understood that if the car he left standing while the air substitute is in this state, the tire will, as it cools, solidify, and develop flats.

As this state of things necessitates, as a rule, the complete destruction of the cover before it can be removed from the rim it is very apparent that economy is not, in the case of such a filling, its strong point.

Numerous similar instances experienced in the past have naturally had the effect of prejudicing the minds of users, and the majority have naturally concluded that by sticking to pneumatic tires they are choosing the lesser of two evils.

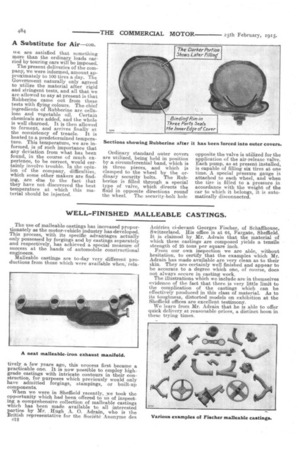

One of the latest examples of such fillings, and one which is apparently immune from such troubles as that described, is that manufactured by Rubberine, Ltd., of The Campsbourne, High Street, Hornsey, London, N.

We were informed from an authoritative source that a considerable number of vehicles for our own Services as well as for those of the allied Governments, were being supplied with Rubberine-filled tires, and we, therefore, made it our business to have a few words with the manager of the company as to the possibilities of this material, with view to being able to give small users the benefit of our considered opinion. We found the works engaged in filling tires for the Admiralty. We are unfortunately not privileged to give particulars of the cars on which these wheels are to run, but

vve are satisfied that something more than the ordinary loads carried by touring cars will be imposed. The present deliveries of the company, we were informed, amount approximately to 100 tires a day. The Government naturally only agreed to utilize the material after rigid and stringent tests, and all that we are allowed to say at present is that Rubberine came out from these tests with flying colours. The chief ingredients of Rubberine are cellulose and vegetable oil. Certain chemicals are added, and the whole is well churned. It is then allowed to ferment, and arrives finally at the consistency of treacle. It is heated to a predetermined temperature. This temperature, we are informed, is of such importance that any deviation from what has been found, in the course of much experience, to be correct, would certainly involve trouble. In the opinion of the company, difficulties, which some other makers are finding, are due to the fact that they have not discovered the best temperature at which this material should be injected. Ordinary standard outer covers are utilized, being held in position by a circumferential band, which is in three pieces, and which is clamped to the wheel by the ordinary security bolts. The Rubberine is filled through a special type of valve, which directs the fluid in opposite directions round the wheel. The security-bolt hole opposite the valve is utilized for the application of the air-release valve. Each pump, as at present installed, is capable of filling six tires at one time. A special pressure gauge is attached to each wheel, and when the tire is filled to a pressure in accordance with the weight of the car to which it belongs, it is automatically disconnected.