Special Steels for Motor Vehicles.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

The Teutunic Steel Works, Limited, although it is the ,owner of a singularly "German" name, is in "no way connected with the " Fatherland," but makes all its steels at Rock.ingham Street and Attercliffe Road, Sheffield, by the aid of British labour and capital. As specialists in the manufacture of high grade steels, this company has introduced several brands, specially to meet the demands of manufacturers pt. .motorcars, motorbuses, vans end lorries ; these steels are all the product of the crucible. In all its Nickel steels, the Teutonic Company aims at big margins of safety, by endeavouring to secure high tensile strength, high yield point, and relatively large elongation. How far its steels go to meet these three important requirements will best be understood, by engineers, on reference to our table, which gives all the three factors named, as well as the shearing strength.

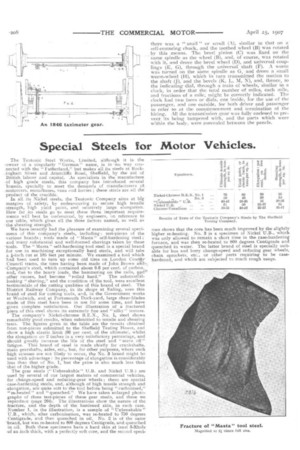

We have recently had the pleasure of examining several specimens of this company's steels, including: test-pieces of the various brands ; tools made of Masta " self-hardening steel ; and -many substantial and well.formed shavings taken by these -tools. The Masta" self-hardening tool steel is a special brand for use in machining exceptionally hard steels, and will take a 1-inch. cut at 185 feet per minute. We examined a tool which had been used to turn up some old tires on London Courly Council trams, the tires having been made of John Brown andCompany's steel, which contained about 0,6 per cent, of carbon, and, due to the heavy loads, the hammering on the rails, a.nd other causes, had become " rolled hard," The substantiallooking shaving," and the condition of the tool, were excellent testimonials of the cutting qualities of this brand of steel. The District Railway Company, in its shops at Ealing, uses this brand of steel for cutting tools, and, in the Government works at Woolwich, and at Portsmouth Dock-yard, large shear-blades made of this steel have been in use for some time, and have given complete satisfaction. Our illustration of a fractured piece of this steel shows its extremely fine and " silky " texture.

The company's Nickel-chrome BEN., No. 1, steel shows remarkably good results, when submitted to tensile and shearing -tests. The figures given in the table are the results obtained from test-pieces submitted to the Sheffield Testing House, and show a high elastic limit (86 per cent, of the ultimate), whilst the elongation on 2 inches is a very satisfactory percentage, and should greatly increase the life of the steel and "stave off" fatigue. This brand of steel is made chiefly for crankshafts, -main gearshafts, axles, etc., but, for other purposes, where such high stresses are not likely to occur, the No. 3 brand might be used with advantage : its percentage of elongation is considerably less than that of No. 1, but the price is also much less than that of the higher grade.

The gear steels t" Unbreakable" U.B. and Nickel U.B.) are used by several of our largest makers of commercial vehicles, for change-speed and reducing-gear wheels ; these are special case-hardening steels, and, although of high tensile strength and • elongation, are quite soft to the tool before being "carbonised," " re-heated " and "quenched." We have taken enlarged photographs of three test-pieces of these gear steels, and these we reproduce page 204). The illustrations show the nature of the fracture, and the depth of the hardened skin, in each case. Number 1, in the illustration, is a sample of " Unbreakable " U.B., which, after carbonisation, was re-heated to 750 degrees Centigrade, and then quenched in oil. No. 2 is of the same 'brand, but was re-heated to 800 degrees Centigrade, and quenched in oil. Both these specimens have a hard skin at least 3-32nds -of an inch thick, with a perfectly soft core, and the second speci men shows that the core has been much improved by the slightly higher re-heating. No. 3 is a specimen of Nickel U.B., which was only allowed to remain a short time in the case-hardening furnace, and was then re-heated to 800 degrees Centigrade and quenched in water. The latter brand of steel is specially suitable for bus and lorry change-speed and reducing gear wheels, chain sprockets, etc., or other parts requiring to be casehardened, and which are subjected to much rough usage.