Patents Completed.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

A New Pressed-steel Wheel. Detachable-rim Improvements. An Unusual Bus-body. Rover Heavy-vehicle Rear Axles.

Copies of complete specifications of the patents published on this page can be obtained from the Sales Branch, Patent Office, Holborn, W.C., at the cost of sixpence for each specification.

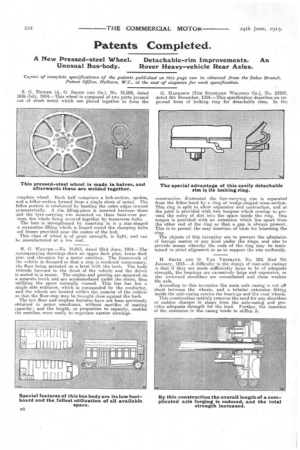

S. G. Diesxn {A. 0. SMITH AND Co.), No. 16,928, dated 16th July, 1914.—This wheel is composed of two parts pressed out of sheet metal which are placed together to form the 2oroplete wheel. Each half comprises a. hub-section, spokes, and a felloe-section formed from a single sheet of metal. The felloe portion is reinforced by bending the outer edges inward symmetrically. A rim filling-piece is inserted between them and the tyre-carrying rim mounted on these bent-over perions, the whole being secured together by transverse bolts. The hub is strengthened by inserting in it a star-shaped 'r serpentine filling which is looped round the clamping bolts ind bosses provided near the centre of the hub.

This class of wheel is of great strength, is light, and can be manufactured at a low cost.

H. G. IAIzaven.—No. 15,013, dated 23rd June, 1914.—The accompanying drawings show an upper deck plan, lower deck plan and elevation for a motor omnibus. The framework of the vehicle is dropped so that a step is rendered unnecessary, the floor being mounted on a level with the kerb. The body extends forward to the front of the vehicle and the driver is seated in a recess. The engine and gearing are mounted on a separate truck and are accommodated under the stairs, thus utilizing the space normally wasted. This bus has but a single side entrance, which is commanded by the conductor, and the wheels are located within the contour of the vehicle so that the floor-step may be brought close against the kerb.

The low floor and atepless features have not been previously obtained in motor omnibuses, without sacrifice of seating capacity ; and the length, in proportion to capacity, enables the omnibus more easily to negotiate narrow turnings. G. HARRISON (THE STANDARD WELDING CO.), NO. 23757, dated 8th December, 1914.—This specification describes an im• proved form of locking ring for detachable rims. In the

construction illustrated the tire-carrying rim is separated from the feline band by a ring of wedge-shaped cross-section. This ring is split to allow expansion and contraction, and at the joint is provided with two tongues which overlap to prevent the entry of dirt into the space inside the ring. One tongue is provided with an extension which lies apart from the other end of the ring so that a gap is always present. This is to permit the easy insertion of toots fcr loosening the ring.

The objects of this invention are to prevent the admission of foreign matter of any kind under the rings, and also to provide means whereby the ends of the ring may be maintained in strict alignment so as to support the rim uniformly.

H. SMITH AND G. VAN VESTRAUT, No. 289, filed 7th January, 1915.—A difficulty in the design of rear-axle casings is that if they are made sufficiently large to be of adequate strength, the bearings are excessively large and expensive, or else awkward shoulders are necessitated and these weaken the axle.

According to this invention the main axle casing is cut off short between the wheels, and a tubular extension fitting inside the axle-casing carries the bearings and the road wheels. This construction entirely removes the need for any shoulders or sudden changes in shape from the axle-casing and provides adequate strength for the load. Further, the insertion of the extension in the casing tends to stiffen it.