DOWNDRAU RAISES 11 T INDUCTION ORMANCE

Page 50

Page 51

Page 52

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

By L. J. COTTON, M.I.R.T.E. AREMARKABLE improve7 ment in performance and fuel consumption has been attained in the Crossley coach chassis by the modification of the air induction system to the engine. Whereas with the previous arrangement, 100 b.h.p was developed at 1,750 r.p.m , the new " downdraught " system provides 114 b.h.p. at the Same engine speed. The extra power is obtained purely by the induction system. including the rearrangement of the inlet ports in the cylinder head. These are now placed vertically and apart from the exhaust ports Previously, the air-intake manifold was adjacent to the exhaust branch, but in the new head air is drawn from the coorside of the engine.

That this increase in power may be interpreted in more miles per gallon was proved by a road test of a coach chassis, with the modified power unit and fivespeed overdrive-top gearbox, when the consumption rate worked out to 19.8 ntp.g. This supports the theory outlined in Mr, Beart's article "Greater Power—Greater Economy," in the two previous pages.

The Crossley 8.6-litre six-cylindered direct-injection oil engine has a monobloic alloy-east-iron cylinder block, which is bolted to the aluminium-alloy crankcase, with air-hardened liners fitted in the block. Strip-bearings coated With lead-indium are used for all the main bearings, whilst the connecting-rod bearings are Crometlined. This is a modification because previously the lower parts of the big-end bearings were lined with white metal. Fitted with a torsional vibration damper at the front, the crankshaft has nitrided crankpins and journals, seven bearings supporting the shaft in the crankcase. Lubricating oil is drawn through a strainer and delivered through an Auto-Klean filter to the bearings. A secondary pump delivers oil to the timing chain and valve gear.

Engine and clutch are retained as a unit in the frame on Silentbloc mountings, the arrangement at the clutch housing comprising four rubber bushes attached through brackets to the periphery of the housing, and to the frame banjo member. A short propeller shaft with a Hardy Spicer coupling at the front and a Layrub. unit i16 at the rear conveys the drive to the gearbox, which is placed amidships in the chassis... The gearbox is also carried on a rubber-mounted crossmember attached to the rear of its

casing. An alternative four-speed

. gearbox has a banjo-type inotintinI. for -attachment to the engine an clutch

• The Crossley five-speed gearbox

provides constant mesh on all ratios except first and reverse. The overdrive-top, in conjunction with a 6-161, final drive, gives a maximum governed speed of 57 m.p.h. Behind the searbox. the two-piece propeller shaft has three Hardy

Spicer universal joints. Chassis suspension is by long semi-elliptic springs, underslung at • the rear axle, and Newton hydraulic shock absorbers at a]! wheels.

The frame is suitably braced with tobuia.r and pressed-ste,c1 cross-members, a detachable drop extension at the rear being provided to suppori a deep luggage compartment. A Clayton Dewandre. triple servo -braking system is used, the rear. brakes being operated from the master servo, whilst independent servos mounted direct on the stub axles operate the front brakes.

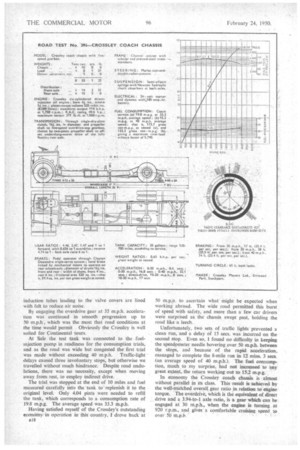

Before starting the test we Proceeded to the weighbridge, where he running weight was found to be 82 tons. Although this weight is representative of luxury coach with a full complement of passengers, it does not make any allowance for luggage, which for 32 passengers might amount to an extra ten. The distribution weight showed that 45 per cent of the load was carried by the front axle. The proportion would. of course, be less when carrying luggage at the real. To accommodate the load distribution, 9.75 by 20-in. tyre equipment is provided at the front, and 9.00 by 20-in, twin tyres at the rear

Because the test vehicle was essentially a long-distance coach chassis, the consumption trials were made over a, representative course on the A.50 road between Sale and Northwich. I soon noticed the rapid acceleration and the smooth running of the engine. There is slightly more induction roar from the modified engine, but it would not be noticed by passengers ina coach. The

induction tubes leading to. the valve covers are lined with felt to reduce air noise.

By engaging the overdrive gear at 35 m.p.h. acceleration was continued in smooth progression up to 50 m.p.h., which was the most that road conditions at the time would permit Obviously the Crossley is well suited for Continental tours.

At Sale the test tank was connected to the fuelinjection pump in readiness for the consumption trials, and as the road was wide but congested the first trial was made without exceeding 40 m.p.h. Traffic-light delays caused three involuntary stops, but otherwise we travelled without much hindrance. Despite road undulations, there was no necessity, except when moving away from rest, to employ indirect drive.

The trial was stopped at the end of 10 miles and fuel measured carefully into the tank to replenish it to the original level. Only 4.04 pints were needed to refill the tank, which corresponds to a consumption rate of 19.8 m.p.g. The average speed was 33.3 m.p.h.

Having satisfied myself of the Crossley's outstanding econoiny in operation in' this country, I drove back at 818 50 m.p.h. to ascertain what might be expected when working abroad. The wide road permitted this burst of speed with safety, and more than a few car drivers were surprised as the chassis swept past, holding the road like a leech.

Unfortunately, two sets of traffic lights prevented a clean run, and a delay of 15 secs, was incurred on the second stop. Even so, I found no difficulty in keeping the speedometer needle hovering .over 50 m.p.h. between the stops, and because of the rapid acceleration, managed to complete the 8-mile run in 12 mins. 3 secs. (an average speed of 40 m.p.h.). The fuel consumption, much to my surprise, had not increased to any great extent, the return working out to 15.2 m.p.g.

In economy the Crossley coach chassis is almost without parallel in its class. This result is achieved by the well-matched overall gear ratio in relation to engine torque. The overdrive, which is the equivalent of direct drive and a 3.94-to-1 axle ratio, is a gear which can he engaged at 30 m.p.h., when the engine is turning at 920 r.p.m., and gives a comfortable cruising speed to over 50 m.p.h Seated over the gearbox on the open chassis, I detected a slight whine when the overdrive was used, but the noise might not be detected when the body was fined: I found direct drive, with an overall ratio of 6 to 1, a useful gear between 21 m.p.h. and 36 m.p.h., and with a high power-to-weight ratio, it was sufficient to meet the demands of the steeper main-road inclines.

Starting on I in 4 Gradient

The 11-rride Snake Hill was a third-gear climb-, and instead of being a test of performance, the trial developed into a comfortable four-minute ride. The radiator -temperature rose 6 degrees during the climb, to reach'. a maximum of 134 degrees F. Ambient was .48degrees F. A more severe test was required, so a detour. was 'made, on the return to Stockport, to a local

hill:of 1 in 4. The inclines leading to this gradient required the use of third gear, and then the driver engaged second and—still more hastily—bottom gear. There was plenty of power available for a stop-start test, • and the hand brake held the chassis, without creeping, while we stopped to collect the photographer.

The 'acceleration trials demonstrated the good matching of the intermediate ratios. Using second gear when moving away from 'rest, the run from 0-20 m.p.h. occupied :16:8 sees. arid; engaging overdrive at 37 m.p.h.,

we reacheci:=10 m.p.h. in '-32 Sees The relatively low. axle ratio affords a good' acceleration rate in direct

drive, and we increased speed 'from 10-30 in

that gear, in 17 .sees. Good performance is clearly

obtainable without frequent gear changes: .

With a brake frictional area approaching 60 sq. ins. per ton as tested, and a Clayton Dewandre triple-servo system, the deceleration rate was ample for all requirements; the .average stopping distance from 30 m.p.h. being 38 ft. An emergency application of the pedal

from 40 m ph. brought the chassis to rest in 74 it Because of traffic conditions, further tests at higher speeds were out of the question.

I enjoyed driving the .Crossley dating the 90 mile test. The smooth running in the overdrive gives a false impression or speed, and drivers in this countrywill have to keep a watchful eye on the speedometer. The addition of Ne..vton hydraulic shock absorbers to the

suspension makes some of the worst road surfaces appear good and was effective when cornering at speed.

The gear change permits straightforward operation without any out-of-sequence movement of the ballchange lever. In effect, there is a six-position gate with three notches on each side of a 'transverse movement.