RIO 10 HOPKINSON.

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

time, cart be worn down as clo.se as possible to OH.. \■ heel. This latter item is very important, for the %vast, rubber which is still sound when tyres require renewal is a great factor in the price of tyre upkeep.

To emphasise the trend of tyre construction in the direction of width, Figs. 5 and 9 illustrate sections of tyres shown at Olympia : these prove that efforts have been made in the direction of a wide tyre that is not too thick. In this connection, it must be noted that the Hopkinson tyre (Fig. to) is made with a double tread, and a quadruple tread is obtained when twin tyres are used. Some doubt may be raised as to whether this point is of consequence, because the double tread will soon wear off, and the tread will be flat for the remainder of the life of the tyre.

The methods of attachment of the tyre to the rim of the wheel present, to-day, the greatest variety. This b, however, an extremely important point, as is witnessed by the fact that many motor omnibuses have been running in London, on many occasions during the past summer, with the tyres half out 4)f their fastenings. The creeping ot the tyre inside the rim must be prevented at all costs, bid the difficulty is that the tyre tends to roll out and rapidly to elongate, unless it is effectually secured to the rim of the wheel. If any readers of. this article have experience which dates bark to the time of the ordinary bicycle, they vill remember that it was necessary periodically to take the tyre off, to cut it piece out, and then to re-cement it on the rim. Such methods are quite impracticable with motor tyres, and it is necessary to adopt a fastening that will prevent both creeping and elongation. The first methcd of fastening is that of the CFncher, illustrated in Figs. t, 17, and 3. Fig.. is a section of a Clincher tyre, made by the North British Rubber Company, and ri;.;-. 2 a section of the Royal Siedar Buffer tyre. This type of fastening is adopted in 'fixing the De Nevers (Fig. 3) and Imperial tyres. It requires no inconsiderable power to force the lyre into the rim, and, in fact, it is best to send the wheel to the rubber company when they require re-tyring, as they have special tools for this purpose. This is impracticable with public service vehicles, for which it is necessary to stock the tyres complete with their steel rims and to put these on to the wheels as a .single piece, securing them with a loose flange.

The De Neyers tyre, shown by J. Liversidge and Son, Limited, requires further description, as it is a praiseworthy attempt to solve the difficulty of creeping by tyre construction instead of entirely by the method of attachment. Fig. 3 is an illustration of this tyre, and it will be seen that the tmad practically consists of a number of sections, each of

which is independent of the next, although the common base is clinched into the rim in the ordinary way. This tyre is not endless, but is virtually made so by a number of wires which are inserted into the ends of the tyre and which ex. tend for a few inches on each side of the joint. The cross grooves on this tyre undoubtedly go a long way towards the prevention of skidding.

The second method of attachment, illustrated in Fig. 4, is to vulcanise the rubber tyre to a steel band, which band makes the tyre inextensible. The tyre illustrated is the Dunlop solid tyre, and it will be noticed that the endless steel band is of special section. To this steel band, a very hard vulcanite (shown black in section:, is first attached, and the remainder of the mould is filled up with ordinary rubber. If soft rubber were employed in the spaces provided in the steel band, it would soon work loose, because of the internal movement and heating, 1 it by using .bed of vul this danger is obviated. The Polack and the Peter Un i o n tyres are also vulcanised to a steel band; but were not exhibited at Olympia, except on vehicles. This, however, is good evidence of their real worth in daily service.

Fig. 5 shows t he fastening o m p lmed on Continental and on Goodr i c h tyres. The short lengths of cross

wire' are ern%MI NM

FIG II CLINCHER GRID.

O 1r )00 • rm. ) E

from( )

( )

Li

( )

O 0 • 0

O O,

O 0 O 0 O 0

(

) ) )

)

)

1.)

)

( 1

beC ded ill the • Xei &Ws 0

rubber before

vulcanisa t ion E3 at intervals of

about one inch.

When the tyre has been forced into the rim two circumferential wires are forced on over the flanges to nip the ends of the short cross wires. There is another form of wired-on tyre marketed by David Moseley and Sons, Limited, in which four endless wires are moulded in the tyre before vulcanisation. Fig. 6 shows a section of a twin tyre of this make. The twin tyre has been selected for illustration in this case, because a particularly neat form of rim and flange is employed. The Bull tyre, which is made by the Shrewsbury and Chaffiner Tyre Company, is a combination of the clinched and wired types : the tyre (Fig. 7) is not made endless : it is cut to length, forced into the rim, has two wires threaded through the holes in the rubber,

anti then these wires are electrically welded where their ends butt, after which the joint so formed is vulcanised. The same company also makes the Giant and the World tyres, to be used in conjunctien, the former on the front wheels and the latter on the back wheels. The Giant tyre is sped(lily designed to take the side strain that comes on the tyre of a steering wheel---a strain which not infrequently pulls a clinched tyre out of the rim. This tyre is shaped so that the pull does not tend to take it out of the rim, and the flanges are held by bolts at an angle of about 3odeg. instead of horizentally. The World tyre has a twin-tread tyre, made in

one piece, and held by detachable flanges. The makers find the continuous rubber base to give increased resilience.

.1 remarkable attachment is that of the Ducasble tyre (Fig. 8), which is manufactured by the North British Rubber Company. This tyre was originally made for the French market, where it has met with much success. It will be noticed that a continuous steel band passes through the centre of the tyre, and that mushroom-headed bolts are inserted at intervals, the nuts being on the inside of the felloe. The ordinary form is that illustrated in Fig. 8, which shows

a 90111111. tyre, but Fig. 9 shows a specially-wide form (e,5mm.) with two steel bands in it. Loose flanges have already been illustrated in Fig. 6; they are used in conjunction with many forms of tyre that have been made inextensible by wires or steel bands. The Hopkinson tyre (Fig. to), however, depends on loose flanges alone, but the inner sides of the flanges are serrated, and get a tremendous grip when tightened up.

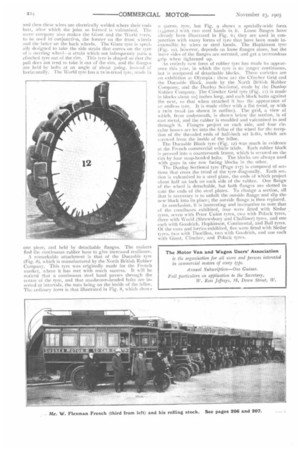

An entirely new form of rubber tyre has made its appearance this year, in which the tyre is no longer -continuous, but is composed of detachable blocks. Three varieties are on exhibition ai Olympia : these are the Clincher Grid and the Ducasble Block, made by the North British Rubber Company, and the Dunlop Sectional, made by the Dunlop Rubber Company. The Clincher Grid tyre (Fig. it) is made in blocks about tol inches long, and each block butts against the next, h o that when attached it has the appearance of ac endless tyre. It is made either with a flat tread, or with a twin tread (as shown in outline). The grid, a view of which, from underneath, is shown below the section, is of east metal, and the rubber is moulded and vulcanised to and through it. Flanges project on each side, and four circular bosses are let into the felioe of the wheel for the reception of the threaded ends of half-inch set btnits, which are eerewed (ruin the inside of the felloe.

The Ducashle Block tyre (Fig. 12) was much in evidence at the French commercial vehicle trials. Each rubber block is pressed into a countersunk frame, which is secured on the rim by four snap-headed bolts. The blocks are always used with gaps in one row facing blocks in the other. The Dunlop Sectional tyre (Page 217) is composed of sections that cross the tread of the tyre diagonally. Each section is vulcanised to a steel plate, the ends of which project about half an inch on each side of the rubber. One flange of the wheel is detachable, but both flanges are slotted to take the ends of the steel plates. To change a section, all that is necessary is to unbolt the outside flange and slip the new block into its place; the outside flange is then replaced.

In conclusion, it is interesting and instructive to note that of the omnibuses exhibited, four were fitted with Sirdar tyres, seven with Peter Union tyres, two with Polack tyres, three with World (Shrewsbury and Challiner) tyres, and one each with Goodrich, I lopkinson, Continental, and Bull tyres. Of the vans and lorries exhibited, five were fitted with Sirdar tyres, two with Thorillon, two with Goodrich, and one each with Giant, Clincher, and Polack tyres.