MODERN FACTORY PLANNING.

Page 23

Page 24

If you've noticed an error in this article please click here to report it so we can fix it.

A Description of the New Tilling-Stevens Factory at Maidstone.

THE CASUAL visitor to the town of Maidstone could hardly fail to notlee the factory of Tilling-Stevens Motors, Ltd., which occupies a very fine position on the banks of the River Mectway at the side of the main line of the S.E. and C. Railway, from London to the coast. The major portion of this factory, the building of which was commenced early in 1917, and which was delayed by the conditions produced by the war, consists of a large ceutre block of five spacious stories, 318 ft. 10 ins. long and61 ft. 8 ins, wide overall, with blocks on both sides of the five stories, _ all built in reinforced concrete. The new factory adjoins the single-storey building which at one time comprised the entire works of the company. Provision is made at two ends of the building for further extensions, so that when completed the factory will be approximately twice its present size.

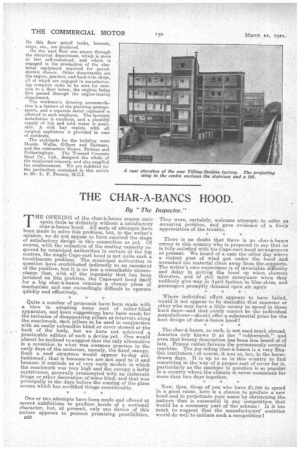

The plan of the first floor, which ewe reproduce herewith, gives a general idea of the lay-out of the five floors. The height of the first three stories is •14 ft., the other two being 15 ft. high. The columns are set out to form bays 20 ft. long by 20 ft. wide.

• The floors, which are designed to carry a superimposed load of 150 lb. per sq. ft., are formed of slabs 3 ins, thick resting on secondary beams 16 ins, deep by 6 ins, wide, which run across the build, ing and divide the bays into three equal parts, and are carried on main beams 24 ins. deep by 8 ins. wide. All the beams have 3 in. diameter holes pierced through them to facilitate the carrying of pipes and . cables ; they have also either " slotted inserts " or "bolt hanger sockets " cast in the underside of them for the attachment of the mechanical equipment required for the shops, such as Motors and shafting.

The site being so near the river, execution of the foundations for the columns presented some difficulties, as not only was water met with in the excavations, but the majority of the column bases had to be taken down to a depth of 17 ft. below ground-floor level before soil of a suitable bearing value could be reached. All these long columns are tied together

by means of a steel reinforcement cast into the ground-floor slab.

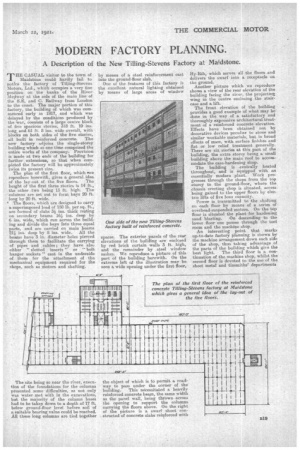

One of the features of this factory is the excellent natural lighting obtained by means of large areas of window

spaces. The exterior panels of the rear elevations of the building are enclosed by red brick curtain walls 3 ft. high, and the remainder by steel window sashes. We reproduce a picture of this part of the building herewith. On the extreme left a the illustration may be seen a wide opening under the first floor, the object of which is to permit a roadway. to pass under the corner of the

building. This necessitated a heavily reinforced concrete beam, the same width as the panel wall, being thrown across the opening to support the columns carrying the floors above. On the right of the picture is a swarf shoot constructed of concrete slabs reinforced with By-Rib, which serves all the floors and delivers the swarf into a receptacle on the ground. Another picture which we reproduce shows a view of the rear elevation of the building facing the river, the projecting wing in the centre enclosing the staircase and a lift.

The front elevation of the building provides a good example of what may be' done in the way of a satisfactory and thoroughly expressive architectural treatment of a reinforced concrete elevation. Effects have been obtained not by decorative devices peculiar to stone and similar workable materials, but in broad effects of mass, with surface finishes and flat or low relief treatment generally. There are six stories at this part of the building, the extra storey being a small building above the main roof to accommodate the case-hardening shop. The building is _centrally heated throughout, and is equipped with an essentially modern -plant. Work progresses through the shops from the top storey to the ground-floor,, where the chassis erecting shop is situated, access: being gained to the upper floors by electric lifts of five Tons capacity.

Power is transmitted to the shafting on each floor by means of a series of overhead-suspended motors. On the top floor is situated the plant • for hardening sand bloating. On descending to the lower floor one passes through the tool room and the machine shop. An interesting point that marks up-to-date factory planning is shown by the machine Arrangement down each side of the shop, thus taking advantage of the parts of the building which give the

best light. The third floor is a continuation of the machine shop, whilst the second floor is devoted to the use of the sheet metal and tinsmiths' departments

On this floor petrol tanks, bonnets, trays, etc., are produced.

On the next floor one passes through the electrical department, which is more or less self-contained, and which is engaged in the production of the electrical equipment required for petrolelectric chassis. Other departments are the engine, gearbox, and hack-axle shops, ill of which are engaged in manufacturing complete units to be sent for erection to a floor below, the engines being first passed through the engine-testing department. The workmen's dressing accommodation is a feature of the planning arrangements, and a separate metal cupboard is allotted to each employee. The lavatory installation is excellent, and a plentifia supply of hot and cold water is available. A sick bay replete with all surgical appliances is provided in case of accidents.

The architects for the building were Messrs. Wallis, Gilbert and Partners, and the contractors Messrs. .Patman and Fotheringharn. The Trussed Concrete Steel Co., Ltd., designed the whole of the reinforced concrete, and also supplied the reinforcement. We are indebted for the particulars contained in this article to Mr. L. P. Francis, •M.C.I.