BUS RECONDITI IN FOUR DAYS.

Page 12

Page 13

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

AT PRESENT the overhaul of a London General bus, carried out in one of the many garages of the company, occupies 16 days, and, therefore, entails the loss of nearly 4i per cent, of the vehicle's working capacity, because a bus undergoes this complete dock overhaul at the end of every year of service.

To have reduced the time to 16 days has, hitherto, been looked upon by all good judges of such matters as representing the height of efficiency. How, then, are we to regard the present intentions of the directors, acting through the chief engineer and his staff, to reduce the time still further—to four days? This means that the time loss of working capacity would be brought down to a shade over 1 per cent., and it is undoubtedly true to say that no piece of machinery in any branch of human service attains equal efficiency. The running time of a railway engine compared with the time occupied in overhaul is considerably smaller. Upon a well-tended sta tionary engine many hours per week are spent in work equivalent to that which occupies only 22 hours in the whole year on a bus mechanism.

The great. saving in time thus foreshadowed is being effected by the concentration of all the bus overhauling in one extensive works now under •eonstruction at Chiswick. Here, a bus, after the sur7 render of its licence to the police, will have its body removed on the coach-building side of the works, will be driven as a chassis to the other end of the works, there dismantled, and will emerge at the end of the same day, a completely overhauled unit, ready

for testing, painting, and , equipment with bodY which will occupy the remaining three days.

Carrying out the overhaul within the four walls of a single building, beyond the saving of time, will mean a saving of labour and reduction of risk. When a bus now comes off service for its dock overhaul its licence plate is surrendered, and then it has to be driven to the coach factory, where the body is removed. It is then driven back to its garage for the chassis overhaul, at the conclusion of whiclvit is sent to the central testing depot, when the chief engineer's staff inspects the operation and thus secures the uniformity which is so desirable. The chassis may even not come up to standard, and then would have to go back to the garage for further attention and return to the central test depot. Afterwards it is sent to the coach , factory, and is painted and equipped with body. Then it must return to the shed for accessories, after which it is free to be submitted to the police for rebeensing.

Concentration of the whoie of the operations will cut out nearly all this dead running. Centralization makes specialization possible and practicable. The work can pass from man to man, each doing his bit, and the result is better work • because, by means of this specialization, the men become more experienced. By careful planning, such as has been brought to-bear at Chiswick, practically all waste motion can be cut out, by passing the work from man to man and from section to section.

The site has been'well chosen : It as central ae any place could be, for the garages of the London.

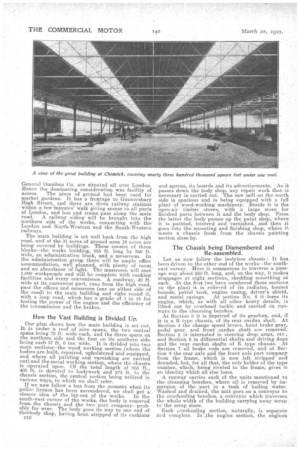

General Omnibus Co. are situated all over London. Hence the dominating consideration was facility of access. The piece of ground had been used for market gardens. It has a frontage to Gunnersbury High Street, and there are three railway stations within a few minutes' walk giving access to all parts of London, and bus and trams pass along the main road. A railway siding will be brought into the northern side of the works, connecting with the London and North-Western and the Sceuth-Western railways.

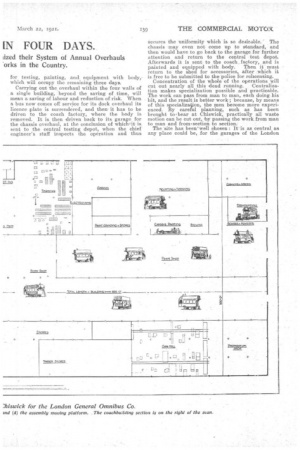

The main building is set well back from the high road, and of the 31 acres of ground area 16 acres are being covered by buildings. These consist of three blocks—the works building, 855 ft. long by 350 ft. wide, an administration block, and a messroom. In the administration group there will be ample office . accommodation, well planned, with plenty of room and an abundance of light. The messroorn will seat 1,000 workpeople and will be complete with cooking facilities and every convenience. A roadway, 40 ft. wide at its narrowest part, runs from the high road, past the offices and niessroom (one on either side of the road) to the main building and right round it, with a loop road, which has a grade of 1 in 15 for testing the power of the engine and the efficiency of the transmission and the brakes.

How the Vast Building is Divided Up.

Our plan shows how the main building is set out. It 4s under a roof of nine spans, the two central spans being 75 ft. wide each, and the three spans on the northern side and the four on its southern side being each 37 ft. 6 inn wide. It is divided into two main sections—the wood working section (where the bodies are built, repaired, upholstered and equipped, and where all painting and varnishing are carried out) and the metal working section, where the chassis is operated upon. Of the total length Of 855 ft., 400 U. is devoted to bodywork and 275 ft. to the chassis section, the central section being utilized in various ways, to which we shall refer.

If we now follow a bus from the moment when its police licence has been surrendered, we shall get a clearer idea oF the lay-out of the works. In the south-west corner of the works, the body is removed from,the chassis and the two part company—probably for ever. The body goes its way to one end of theebody shop, having been stripped of its cushions c10 and aprons, its boards and its advertisements. As it passes down the body shop, any repair work that is necessary is carried out. The saw mill on the north side is spacious and is being equipped with a full plant of wood-working machinery. Beside it is the open-air timber stores, with a large store for finished parts between it and the body shop. From the latter the body passes. up the paint shop, where it is painted, lettered and varnished, and then it goes into the mounting and finishing shop, where it meets a chassis fresh from the chassis painting section close by.

The Chassis being Dismembered and Re-assembled.

Let lie now follow the bodyless chassis: It has been driven to the other end of the works—the southeast corner. Here it commences to traverse a passage way about 250 ft. long, and, on the way, it makes stoppages at eight sections,. shedding something at each. At the first (we have numbered these sections on the plan) it is relieved of its radiator, bonnet boards, petrol tank', engine casing, driver's shield, and metal casings. At section No. 2 it loses its engine, which, as with all other heavy details, is lifted out by overhead tackle and carried On runways to the cleansing benches.

At Section 3 it is deprived of its gearbox, and, if it is a B type chassis, of its rear cardan shaft. At Section 4 the change speed levers, hand brake gear, pedal gear, and front' cardan shaft are removed. Section 5 is interested in steering drop arms, etc., and Section 6 in differential shafts and driving dogs and the rear cardan shafts of K type chassis. At Section 7 all brake rods are removed, and at Section 8 the rear axle and the front axle part company from the frame, which is now left stripped and denuded, but, for all that, the only holder of the type number, which, being riveted to the frame, gives it an identity which all else loses. A runway carries each of the units mentioned to the, cleansing benches, where oil is removed by immersion of the part in a tank of boiling water. Washed and drained, the unit goes on a conveyor to the overhauling benches, a conveyor which traverses the whole width of the building carrying away scrap to the scrap store,

Each overhauling section, naturally, is separate and complete. In the engine section, the engines

are stripped on the benches and conveyed by rollerways to the working benches. Every detail comes in for a thorougVexamination, and any fault is rectified. There is a wonderful machine for bedding-in. crankshafts, and special tools and appliances for rapid and accurate work abound. The engine is erected on an engine conveyor and passes to the test house and then back to a position beside the main moving platform (to which we shall refer). Each -unit—gearbox, steering gear, control gear, universal joint, ete.—is thus treated, the axles traversing their .section, and having wheels removed for retyring, painting and replacement. The frames travel along a runway and have their bolts and rivetia examined and the bushes in the spring hangers and dumbirons replaced. Every part thus travels from the dismantling point, through its overhauling department, to the assembly linebeside the main moving

i

platform. On to this s run a pair of axles, and on to them a frame is swung from the overhead runway, the springs are shackled in place, and, by the time this job is finished, the' moving platform (which is 220 ft. long by 8 ft. wide) has reached the next section, where the brake rods are fitted, and so on, throughout the whole gamut of reassembly.

The Frame, the Foundation for a New Vehicle.

The frame, being the first unit of the whole that originally composed a chassis to get on to the moving platform, will be some hours or even days in front of the other members, and therefore will be fitted with the first engine, the first gearbox, and so on, that are ready. By means of a careful proportioning of the floating number of units, according to the length of time each different class of unit takes in the overhauling, no delays occur in assembling due to unreadiness of units. Thus, the frame which came off the vehicle that was dismembered in the morning can be fully re-equipped by the evening, and, having reached the end of the moving platform, can have its tanks and radiator refilled and be driven off under its own power. As will be seen from the plan, a smithy and millwright's shop and an electrical department are placed on the north side, whilst, between them, ir_ the boiler-house for heating purposes and provision of hot water, and next to it is the rag-washing plant. Next to the boiler-house there is an unloading bay, with a conveyor to carry supplies into the various stores, the other end of the conveyor being the out bank for stores supplied to garages, etc. On the south side are the first-aid department, a laboratory, photographic department, etc., and, further along, a large tinsmiths' shop and a garage. Lavatories will be found at various parts of the

Testing and Completing the Vehicle.

To return to our chassis : this is tested over the road round the works, and, if passed as satisfactory, it is driven to the chassis painting department and there spray painted, passing, when ready, into the mounting and finishing section to receive its body. A final test of the brake gear and of the engine's pulling power is made on the graded road, and the vehicle is ready for Scotland Yard's examination. The test hill is 800 ft. long and the gradient both ways is equal.

The whole operation is a masterpiece of organization.

From the pit dug to form the graded road, many thousands of tons of sand and Thames ballast have been obtained—all that will be required in the building operations, and more. The hole beside the graded road will be used as a dump for the sludge that is taken from the interceptor pits at the .garages. From these as much as 200 tons of mud Per week is collected. By shooting on to their own land the company will save a large weekly putlay. A substantial area of the vacant land will be prepared and turfed as a sports ground for the works

staBITY the middle of April the coachbuilders will be at work, the body construction end of the building having been advanced with that end in view. The existing coach factories at Islington, Fulham, and Notting Hill will eventually be closed as the work is brought to Chiswick. The whole of the building work will be finished by the end of ,Tune and the equipment, with plant and machinery, will have kept pace with it, so that before the summer is well advanced London will have added to its amenities the largest and best organized repair works in the whole country.