Trunk vehicle design and loading

Page 66

Page 67

Page 68

If you've noticed an error in this article please click here to report it so we can fix it.

BY R. P. A. F. WILLIAMS, BA, IVIIMH Assistant general manager, production, Harveys of Bristol Ltd.

MY company has recently put a great deal of thought into the question of transport. Great savings have been made and it is anticipated that greater savings will yet be made.

The problems which presented themselves resolved into three main headings: timing and scheduling of traffic; loading and unloading methods; and vehicle design (about which I wrote in COMMERCIAL MOTOR of March 25, dealing specifically with local delivery vehicles).

It became obvious to us, as to many other firms, that bad scheduling of vehicles, both in and out, was causing a great deal of wasted time, money and effort. Transport operators all over the country realized that large parts of their costs were absorbed in waiting time. At most docks, warehouses and factories, long queues of vehicles could be seen from a very early hour of the morning. Hours might pass before a vehicle even began unloading, and even then further delays might occur through inefficient handling and deployment of labour and machines.

This became a matter of extreme urgency to us about 18 months ago. Analysis showed that not only were hauliers losing considerable time, and consequently expecting to raise their rates, but our own bill for handling and labour was rising by a staggering amount. Our system of loading and unloading had always involved an attempt at scheduling goods in, but loading out had occurred as and when convenient during the day. Loading in particular was dependent on availability of fork-lift trucks, which during the day were in constant demand tending to the needs of the production lines. One obvious answer here would have been to have increased the numbers of fork-lift trucks in the fleet. But this was an expensive answer, and did not really get at the root of the matter, which was poor utilization of existing resources.

Our business is, of course, controlled by Customs rules and procedures, as the dispatches to which I am referring are from a bonded warehouse. After considerable negotiation agreement was reached to build a new internal partition, so that the loading bay and a holding area behind could revert from a bonded to a dutypaid area by official locking of certain doors. Other benefits accrued from this—such as being able to prepare one Customs warrant for all our dispatches of one kind of wine, in one day.

But the greatest benefit was obtained when we scheduled all our dispatches during the evening, when the area became dutypaid. Orders were run-up during the day into the holding area as consolidations of each type of wine. During the evening, vehicles were loaded from this area by our entire fleet of fork-lift trucks. It should perhaps be explained here that by certain Customs rulings we are only able to work in bond during certain specified • hours, so the production lines are not working during this evening and night period. The incoming goods were scheduled in during the day to a carefully regulated programme, with the very helpful co-operation of our suppliers.

The results of this reorganization were staggering. We found that we could load 60 tons of wine an hour, and even in our busiest period were finishing the day far earlier than prior to this plan. The fork-truck drivers appreciated this part of the deal also. They were asked to come in later in the day and were paid for a set period in the evening. During most parts of the year they get away far earlier than their pay time, and certainly earlier than they used to under the old scheme. This form of incentive works very well where it can be applied.

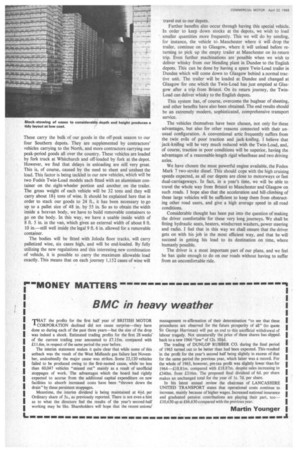

Our dispatches are mainly to our own depots dotted around the country; consequently we can pallet-load most of our goods. Without this factor, the scheme would not have worked so successfully. A lot of contractors' vehicles are involved in this work, and the benefits to them have been as great as to ourselves. They can plan their days much better knowing they will be loaded or unloaded at Harveys to a regular schedule. I feel sure this was a help to us in negotiating reasonable rates during the recent multiple increases.

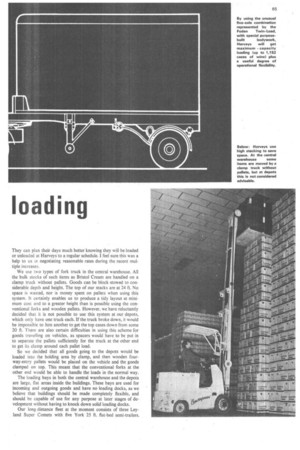

We use two types of fork truck in the central warehouse. All the bulk stocks of such items as Bristol Cream are handled on a clamp truck without pallets. Goods can be block-stowed to considerable depth and height. The top of our stacks are at 24 ft. No space is wasted, nor is money spent on pallets when using this system. It certainly enables us to produce a tidy layout at minimum cost and to a greater height than is possible using the conventional forks and wooden pallets. However, we have reluctantly decided that it is not possible to use this system at our depots, which only have one truck each. If the truck broke down, it would be impossible to hire another to get the top cases down from some 20 ft. There are also certain difficulties in using this scheme for goods travelling on vehicles, as spacers would have to be put in to separate the pallets sufficiently for the truck at the other end to get its clamp around each pallet load.

So we decided that all goods going to the depots would be loaded into the holding area by clamp, and then wooden fourway-entry pallets would be placed on the vehicle and the goods clamped on top. This meant that the conventional forks at the other end would be able to handle the loads in the normal way.

The loading bays in both the central warehouse and the depots are large, flat areas inside the buildings. These bays are used for incoming and outgoing goods and have no loading docks, as we believe that buildings should be made completely flexible, and should be capable of use for any purpose at later stages of development without having to knock down solid loading docks.

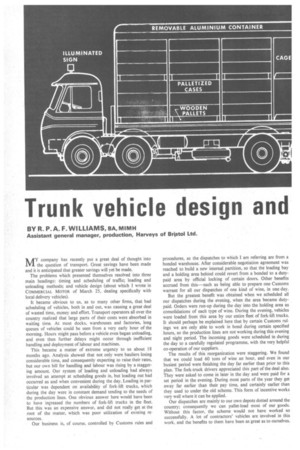

Our long, distance fleet at the moment consists of three Leyland Super Comets with five York 25 ft flat-bed semi-trailers. These carry the bulk of our goods in the off-peak season to our four Southern depots. They are supplemented by contractors' vehicles carrying to the North, and more contractors carrying our peak-period goods all over the country. These vehicles are loaded by fork truck at Whitchurch and off-loaded by fork at the depot. However, we find that delays in unloading are still very great: This is, of course, caused by the need to sheet and unsheet the load. This factor is being tackled in our new vehicles, which will be two Foden Twin-Load models each fitted with an aluminium container on the eight-wheeler portion and another, on the trailer. The gross weight of each vehicle will be 32 tons and they will carry about 18+ tons of wine. It should be explained here that in order to stack our goods to 24 ft., it has been necessary to go up to a pallet size of 48 in. by 55 in. So as to obtain the width inside a boxvan body, we have to build removable containers to go on the body. In this way, we have a usable inside width of 8 ft. 5 in. in the van, which gives an external width of about 8 ft. 10 in.—still well inside the legal 9 ft. 6 in. allowed for a removable container.

The bodies will be fitted with Joloda floor tracks, will carry palletized wine, six cases high, and will be end-loaded. By fully utilizing the new regulations and this interesting new combination of vehicle, it is possible to carry the maximum allowable load exactly. This means that on each journey 1,152 cases of wine will travel out to our depots.

Further benefits also occur through having this special vehicle. In order to keep down stocks at the depots, we wish to load smaller quantities more frequently. This we will do by sending, for instance, the vehicle toManchester where it will drop the trailer, continue on to Glasgow, where it Will unload before returning to pick up the empty trailer at Manchester on its return trip. Even further machinations are possible when we wish to deliver whisky from our blending plant in Dundee to the English depots. This can be done by having a spare Twin-Load trailer in Dundee which will come down to Glasgow behind a normal tractive unit. The trailer will be loaded at Dundee and changed at Glasgow for one which the Twin-Load has just emptied at Glasgow after a trip from Bristol. On its return journey, the TwinLoad can deliver whisky to the English depots.

This system has, of course, overcome the bugbear of sheeting, and other benefits have also been obtained. The end results should be an extremely modern, sophisticated, comprehensive transport service.

The vehicles themselves have been chosen, not only for these advantages, but also for other reasons connected with their unusual configuration. A conventional artic frequently suffers from the twin evils of poor traction and jack-knifing. I believe that jack-knifing will be very much reduced with the Twin-Load, and, of course, traction in poor conditions will be superior, having the advantages of a reasonable-length rigid wheelbase and two driving axles.

We have chosen the most powerful engine available, the Foden Mark 7 two-stroke diesel. This should cope with the high cruising speeds expected, as all our depots are close to motorways or fast dual-carriageways. In fact, in a year's time, we will be able to travel the whole way from Bristol to Manchester and Glasgow on such roads. I hope also that the acceleration and hill-climbing of these large vehicles will be sufficient to keep them from obstructing other road users, and give a high average speed in all road conditions.

Considerable thought has been put into the question ofmaking the driver comfortable for these very long journeys. We shall be fitting hydraulic seats, heaters, windscreen washers, power steering and radio. I feel that in this way we shall ensure that the driver, gets on with his job in the most efficient way, and that he will succeed in getting his load to its destination on time, where humanly possible.

The driver is a most important part of our plans, and we feel he has quite enough to do on our roads without having to suffer from an uncomfortable ride.