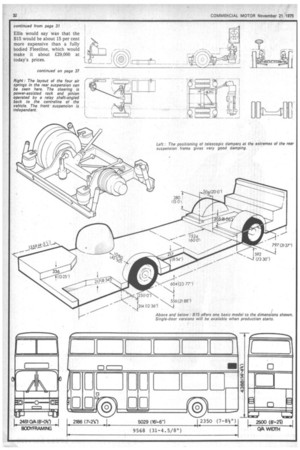

Marketing and construction

Page 33

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

ONCE the B15 comes into production—in 1977—first, the Flee tline, and secondly the Atlantean will cease production. This will leave the Bristol VR in production to satisfy the low bridge and export markets.

Leyland intends to assemble the B15 at the Park Royal works in West London using some body parts assembled by Charles Roe in Leeds and mechanical components built at Leyland, Lancs. Most of the body parts will be built at Park Royal. An earlier plan for London Transport to assemble the BI5 at its Aldenham works has now had to be dropped because of the costs that LT would incur in moving its bus overhaul works from Aldenham to Chiswick. This has thwarted the plan envisaged by Mr Ron Ellis, Leyland Truck and Bus managing director, of eventually " recycling " used B15s to as-new condition alongside the production line of new B 15s at Aldenham.

As well as having a B15 factory in London Leyland has offered an option to Walter Alexanders, the Falkirk bodybuilders, to assemble " kits " of B15 parts in Scotland, but this has not so far been taken up.

At present four B15 prototypes are in existence—three engineering test vehicles, and one for London Transport. fhese will soon be joined by a fifth prototype, which will be offered on test to the PTEs. Noticeably absent from the Leyland development and marketing plans are the National Bus Company and the Scottish Bus Group. They have both indicated their preference to stick to the Bristol VRT, largely because of its Gardner engine.

Initial production is expected to be around 200 in 1978 then slowly building up to around 2,000 buses per year. As for the cost, the most Mr Ellis would say was that the BI5 would be about 15 per cent more expensive than a fully bodied Fleetline, which would make it about £29,000 at today's prices.