STEPPING ON THE GAS

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

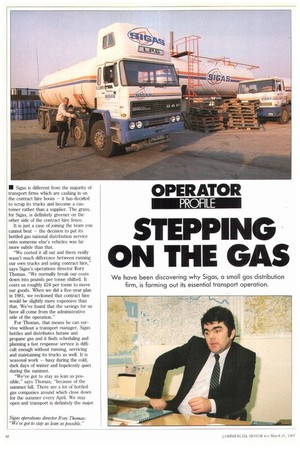

We have been discovering why Sigas, a small gas distribution firm, is farming out its essential transport operation.

• Sigas is different from the majority of transport firms which are cashing in on the contract hire boom — it has decided to scrap its trucks and become a customer rather than a supplier. The grass, for Sigas, is definitely greener on the other side of the contract hire fence.

It is just a case of joining the team you cannot beat — the decision to put its bottled gas national distribution service onto someone else's vehicles was far more subtle than that.

"We costed it all out and there really wasn't much difference between running our own trucks and using contract hire," says Sigas's operations director Rory Thomas. We normally break our costs down into pounds per tonne shifted. It costs us roughly £24 per tonne to move our goods. When we did a five-year plan in 1981, we reckoned that contract hire would be slightly more expensive than that. We've found that the savings for us have all come from the administrative side of the operation."

For Thomas, that means he can survive without a transport manager. Sigas bottles and distributes butane and propane gas and it finds scheduling and planning a fast response service is difficult enough without running, servicing and maintaining its trucks as well. It is seasonal work — busy during the cold, dark days of winter and hopelessly quiet during the summer.

"We've got to stay as lean as possible," says Thomas, "because of the summer lull. There are a lot of bottled gas companies around which close down for the summer every April. We stay open and transport is definitely the major cost centre of our business." That is not surprising, because Sigas is a transport and distribution operation, pure and simple.

The company does not sell its gas on a door-to-door basis at all, though that is how it started in 1980. It buys its gas in bulk from the big petrochemical suppliers like Mobil, Esso, or Shell and bottles it at a purpose-built depot at Poplar, in London's East End. It then distributes the gas to a national network of Sigas-approved and franchised dealers.

Most contract hire customers are ownaccount operators whose main business is anything but transport. Some are children's clothes specialists, like Mothercare, or supermarket chains, like Sainsbury's, but they usually have one thing in common — they see transporting their goods to market as nothing more than a necessary evil.

Sigas is a road distribution company putting its transport out on a third-party contract hire limb because, says Thomas, "I like the predictable and fixed costs contract hire produces. We know what our transport costs are going to be for the next five years. If you know that nothing can spring up and surprise you."

During Sigas's five-month summer recess, fixed costs are a vital asset. Though Thomas would worry about the possibility of trucks standing idle and depreciating in his yard during August, he does not like to contract out his drivers. All of Sigas' drivers are full-time employees, apart from the occasional agency temp during winter's hot spots. "We sell on service," says Thomas, and he does not want his key frontmen — the drivers — to be outside his direct control.

Thomas knows a thing or two about driving: that is where he started. When Sigas was formed in 1980 it had three personnel including managing director Bill Bradley. Thomas was the firm's driver.

Today it has about 30 employees and it is growing fast — around 30% so far every year. The Earl of Arundel, whose money helped get things off the ground, is chairman.

"It's a growing market," says Thomas, especially if you set the operation up to cope with the troughs when demand plummets. The company still processes the gas at its original Allsa Wharf depot in Poplar; it plans to set up a new base somewhere near Swindon in the next six months. Manchester is its most northerly dealership so far.

Sips runs four 16 tonne cylinder carriers — three Fords and a Leyland — with a 32 tonne Ford Cargo artic.

Trailers come from BRS on rental and have specially designed flat-beds fitted with gas bottle frames for Sips. "BRS modified some old flat-beds specially for us," says Thomas. `"rhat's one of the advantages of contract hire — you tell them what you need and they go away and build it."

Sigas is commissioning a new gooseneck trailer to carry more bottles a time. The company loads onto the rear of its trailers and 16 tonners with palletised fork-lift cargoes, and the bottles are transferred off the pallets and stacked on the back of the truck "loose".

When the vehicle gets to the appropriate depot the bottles are unloaded one by one as required from the side_ "We did look into fitting tail-lifts, but they take up too much load space and they're too heavy," says Thomas. "Fitting a halftonne tail-lift would lose us 15 gas bottles on average," he says.

Each gas bottle weighs about 26kg; the gas itself accounts for about half of that.

"Our vehicles are usually only halfloaded because they are always bringing back empties," says Thomas. He has just taken on two new bulk gas tankers. These will be used to go around filling up the large, semi-industrial gas tanks in which farms and remote buildings which are not connected to the national gas grid store butane gas. "They've both got 6.5tonne gas bodies fitted," says Thomas, "and they take about 10 months to build." Both of the new tankers were delivered late. Sigas should have had them on the road last October; in fact the first arrived just before Christmas and the second in February. Thomas is thinking of buying a Seddon Atkinson tanker next time.

The company has no back-up vehicles of its own: -11f we get a breakdown with the special BRS step-frame and they give us a standard replacement — which is normally a dropside — we lose the cylinder frame and its capacity. This cuts

a 350-cylinder load in half," says Thomas.

He thinks that large contract hire firms like BRS treat his operation as an unimportant minnow. "My administrative staff spend too much time on the phone dealing with BRS. Their accounts department is dreadful. Fleetcare took three days to service our first truck, and they also gave us a terrible paint job."

Thomas is now putting his eggs into more baskets and has another contract hire firm in on the act: Comet Vehicle Leasing from Trafford Park in Manchester.

Other problems include running under the stringent carriage of petrol regulations, with fire extinguishers, protected electrical wiring and insulated radiators.

Thomas wants to improve the company's efficiency. He likes the idea of leaving full trailers at his depots and only going up to replace them as they become empty with another full trailer. He has looked at demountable trailers but dismissed them because they are too heavy for a bottled gas operation.

"All our competitors run artics," he says. "We will go more and more into artics in the future. We've also had a good look at drawbars, but they need a good driver."

Probably his most irritating problems come courtesy of good old British bureaucracy: "Liquid petroleum gas is not allowed through the Dartford tunnel so the M25 is completely useless to us," he says. "That is despite the fact that they allow ordinary petrol tankers to go through. I have to go up into London from Poplar and cross the Thames at the next available bridge — Southwark Bridge. It's crazy. We're being forced to run LPG through the city. It could only happen in England."

D by Geoff Hadwick