A New Motor Omnibus Chassis.

Page 19

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

Progress at the New Works of Commercia' Cars, Limited, at Luton.

The new works of Commercial Cars, Limited, of &scot Road, Luton, are now completed. The company bought, a lew months ago, a piece ot freehold land with an area of just over 3i acres. The works are large; they cover acre, and the plant and organisation are both excellent. The production of commercial chassis is, as the title of the company indicates, its legitimate business, but a department established for the sale of various parts of omnibus chassis of the highest quality is a special feature; these will be supplied in any quantity to purchasers.

The svorks are ol square formation, and the main building is divided into four bays : the lighting arrangements are good, and the comfort of the workmen has been carefah), studied, inasmuch as a large hot-ai,r plant has be,2n installed for warming the atmosphere of the works during the wittier months.

The front of the building is devoted to numerous offices, including the drawing otlice. The principal portion of the first bay is utilised as stores, and this is sub-divided into three sections. These are, respectively, rough stores, fin

ished stores, and non-standard stores. The first section contains a large stock of the raw materials used subsequently in the construction of the ports of the chassis manufactured; the second department is divided into numerous lo:kers and pigeon holes, where the finished parts, made from materials drawn from the rough stores, find a resting place; whilst the third, and smallest, room holds a heterogeneous assortment of the small parts which are bought from outside engineering firms.

The rough stores contain a large cold-sawing machine, which cuts, the raw material into the lengths required for making standard parts. The necessary power is derived from a ioh.p. electric motor, and angle-plate, or bar steel can be operated upon up to a maximum depth of N inches. The saw—zo inches in diameter—leaves the work in a practically finished condition, so that hardly any subsequent machining is necessary. The slme bay includes also the en gine-erecting shop, fitted with the usual benches and vices engines are brought here from the machine shop and are lowered into position in the chassis, when the final der:ils :re aAeraiel to.

The second bay is set apart for the building of the chassis and gear-boxes : in fact, all the operations necessary for the building of a chassis are completed in this portion of the works, except the fitting of the engine, which is done, as previously explained, in the department in the first bay.

The third section of the works contains the various machine tools which are required by the fitters who assemble the chassis. These tools include so-rte special ones, which have been constructed in the works to the design of Mr. C. M. Lindley, the engineer to the Company. Among the general enFzineerintr tools in the same :ection is a very fine 40-inch double-disc grinder by Roberts, of Manchester, with a specially large tool table. A most ingenious machine is also placed in the same department ; this has been made fur cutting the cams used in the Company's patent gear-box, and has also been designed by Mr. Lindley. Other tools in

elude a couple of radial drilling machines, bv Swift, M 11 ilifax ; these are arranged side by side in such a way that different-sized holes can be drilled in a side member of a chassis without having to move it after it has been bolted into position. A corner of the same department is enclosed, and contains the stock of tools used in the many machines. The tools for each machine have their index number, and a mechanic can only get a certain attachment out of the stores by handing in one of a corresponding supply of checks bearing the same figures, which are in his possession as user of the particular lathe or tool for the rime being.

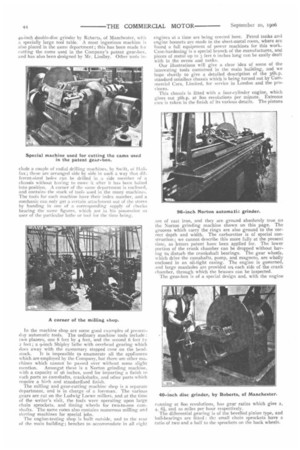

In the machine shop are some good examples of presentday automatic tools. The ordinary machine tools include : two planers, one 8 feet by 4 feet, and the second 6 feet ty 2 feet ; a 9-inch Shipley lathe with overhead gearing which does away with the customary stepped cone on the head stock. It is impossible to enumerate all the appliances which are employed by the Company, but there are other machines which cannot be passed over without some slight mention. Amongst these is a Norton grinding machine, with a capacity of q6 inches, used for imparting a finish to such parts as camshafts, crankshafts, and other parts which require a hierh and standardised finish.

The milling and gear-cutting machine shop is a separate department, and is in charge of a foreman. The various gears are cut on the Ludwig I.oewe millers, and at the time of the writer's visit, the tools were operating upon large chain sprockets, and timing wheels for two-to-one camshafts. The same room also contains numerous milling and slotting machines for special jobs. The engine-testing shop is built outside, and to the rear of the main building; benches to accommodate in all eight engines at a time are being erected here. Petrol tanks and engine bonnets are made in the sheet-metal room, where are found a full equipment of power machines for this work. Case-hardening is a special branch of the manufactures, and pieces of metal up to 3 feet 6 inches long can be easily dealt with in the ovens and tanks.

Our illustrations will give a clear idea of some of the interesting tools contained in the main building, and we hope shortly to give a detailed description of the 36h.p. standard omnibus chassis which is being turned out by Commercial Cars, Limited, for service in London and the provinces.

This chassis is fitted with a four-cylinder engine, which gives out 36h.p. at Soo revolutions per minute. Extreme care is taken in the finish of its various details. The pistons are of cast iron, and they are ground absolutely true on the Norton grinding machine shown on this page. The grooves which carry the rings are also ground to the correct depth and width. The carburetter is of special construction; we cannot describe this more fully at the present Lime, as letters patent have been applied for. The lower portion of the crank chamber can be dropped without having tek disturb the crankshaft bearings. The gear wheels, which drive the camshafts, pump, and magneto, are wholly enclosed in an oil-tight casing. The engine is governed, and large manholes are provided oo, each side of the crank chamber, through which the brasses can be inspected.

The gear-box is of a special design and, with the engine